Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Seasoning Powder Inclined Screw Conveyor is a mechanical device used to convey spice powder, especially for light and dusty powders such as seasoning powder. It conveys seasoning powder from low to high through the rotation of spiral blades, and is suitable for occasions where inclined conveying is required.

The inclination angle of the seasoning powder inclined screw conveyor is a key parameter in its design and use, which directly affects the conveying efficiency and applicable scenarios.

0°-20°: Nearly horizontal conveying, suitable for short-distance and low-height conveying scenarios, such as short-distance conveying in workshops.

20°-45°: Medium inclination angle, suitable for conveying at medium height and distance, such as from the ground to medium-height equipment

45°-90°: Large inclination angle, suitable for conveying with large height differences, such as from the basement to the upper production line.

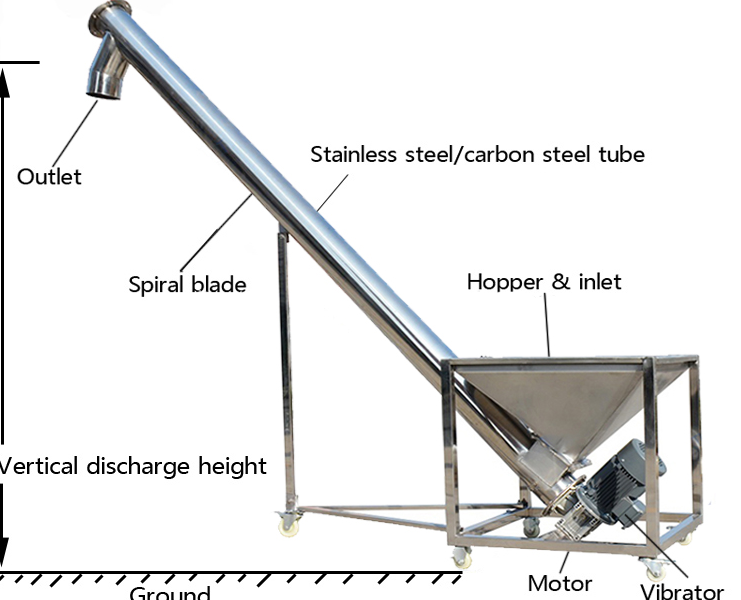

The composition structure of the seasoning powder inclined screw conveyor is roughly similar to other conveyors, mainly composed of the following components.

Screw shaft: responsible for driving the spiral blade to rotate, usually driven by a motor.

Spiral blade: directly contacts the seasoning powder and pushes the material forward.

Conveying trough: accommodates the screw shaft and spiral blade, usually a closed structure to prevent dust leakage.

Feed port and discharge port: used for material input and output respectively.

The seasoning powder enters the screw conveyor casing from the feed port. The design of the feed port focuses on cooperating with the spiral blade so that the seasoning powder falls evenly on the blade. The spiral shaft rotates, and the friction force pushes the seasoning powder to move along the inclined channel. During transportation, various factors affect its speed and stability, and measures are taken to prevent backflow. Finally, the seasoning powder is discharged from the optimized discharge port and enters the next production link.

The seasoning powder inclined screw conveyor has many advantages in the application of seasoning powder, as follows

It can convey a variety of seasoning powders: whether it is common fine powdered seasoning powders such as salt, sugar, and monosodium glutamate, or seasoning powders with a certain granularity such as chili powder and pepper powder, the inclined screw conveyor can convey them well.

Dealing with special seasoning powder: For some hygroscopic and slightly sticky seasoning powders, under appropriate design and operating conditions, the inclined screw conveyor can also prevent the seasoning powder from agglomerating and adhering to the conveying pipe or blades to a certain extent through the rotation and pushing of the spiral blades, ensuring smooth transportation.

Adjustable conveying angle: The inclination angle can be flexibly adjusted according to the layout of the production site and the needs of the process flow. Within a certain range, it can not only achieve smooth transportation at a smaller inclination angle, but also lift the seasoning powder to a higher position at a larger inclination angle to meet the material transportation needs between equipment at different heights.

Ensure powder uniformity: In the process of conveying seasoning powder, the rotation of the spiral blades can make the seasoning powder form a certain stirring and mixing effect in the conveying trough, ensuring the uniformity of the seasoning powder before and after transportation.

Reduce material oxidation: The sealed conveying method reduces the contact area and time between the seasoning powder and the air. For some easily oxidized seasoning powders, it can effectively reduce the degree of oxidation during the conveying process.

The seasoning powder inclined screw conveyor is widely used in many links of seasoning powder processing due to its high efficiency, flexibility and good sealing. The following are its main application scenarios

Raw material transportation: transport the seasoning powder raw materials from the storage silo to the mixing equipment to ensure the continuous supply of raw materials.

Mixing equipment to packaging equipment: transport the mixed seasoning powder to the packaging equipment to ensure that the mixed materials enter the next process in time.

Multi-batch mixing: transport seasoning powder between different mixing batches to ensure production continuity.

Filling equipment: used to transport seasoning powder to the filling equipment to ensure accurate filling and reduce waste.

Connection between equipment: connect different production equipment to ensure smooth transportation of seasoning powder between processes.

Transport of multiple seasoning powders: on the production line producing multiple seasoning powders, use inclined screw conveyors to transport different types of seasoning powders to ensure production flexibility and efficiency.

As a fast and flexible powder conveying equipment, the seasoning powder inclined screw conveyor plays an important role in the food processing industry. Its tilted design, good sealing, strong flexibility and easy cleaning make it an ideal choice for seasoning powder production and packaging processes.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!