Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Corn Pellet Screw Conveyor is an important equipment specially used for conveying corn. It uses vibration force to push the spiral blades to convey corn particles to the target position along the pipeline, which can quickly complete the transfer and storage of corn and improve the production and transportation of corn.

Clean and hygienic: The whole is made of stainless steel to ensure that the corn is not contaminated during the conveying process.

Save manpower: The screw conveyor replaces the cost of manual handling and reduces labor.

No material spillage: The closed structure is adopted, and corn particles will not fall when conveying corn, ensuring the overall yield of corn.

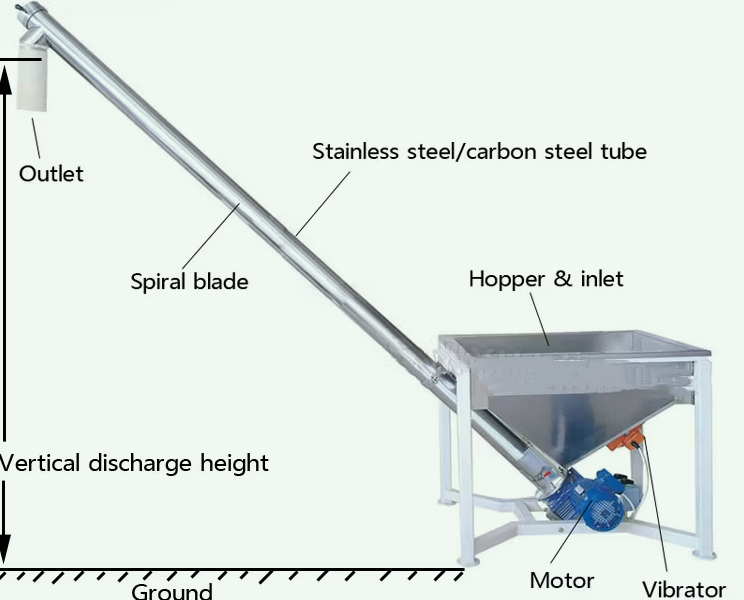

Corn pellet screw conveyors usually consist of the following parts:

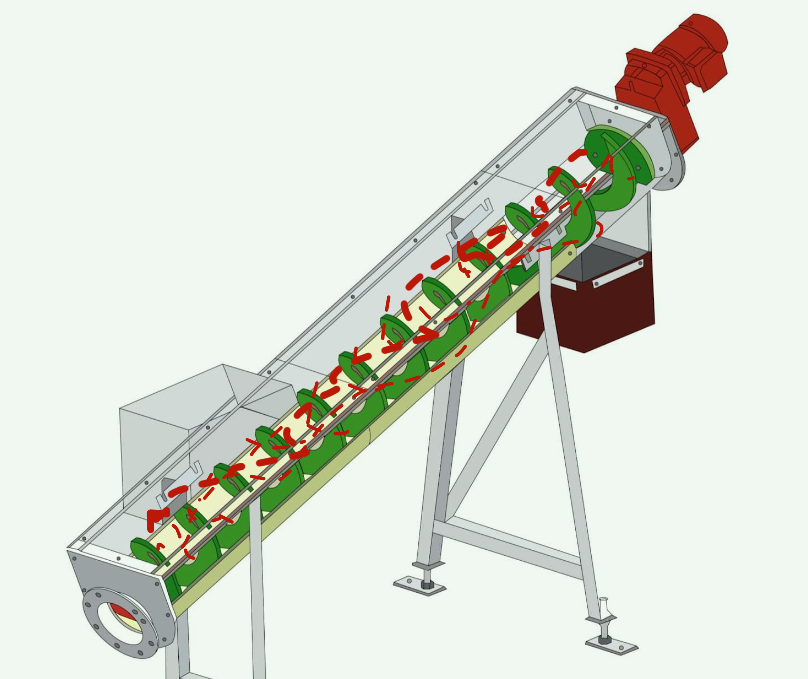

Screw: Responsible for conveying corn particles along the conveyor pipeline to the destination. Generally, stainless steel is used for conveying corn.

Conveyor pipeline: Used to carry and wrap the corn particles to be conveyed.

Hopper: Used to store a certain amount of corn particles to facilitate the conveying process without material breakage.

Transmission: The transmission is the power source of the conveyor, usually including components such as motors and reducers, which are used to drive the rotation of the screw.

Support frame: supports the entire conveyor system to ensure the stability and safety of the conveyor.

The corn pellets are first put into the conveyor pipe through the feed port of the conveyor. As the transmission device drives the spiral screw to start rotating, the corn pellets are pushed from the feed port of the conveyor to the discharge port. Under the push of the spiral screw, a continuous flow is formed along the pipe. The corn pellets are finally output through the discharge port of the conveyor to complete the conveying process.

Customizable: It can customize the appropriate size according to the customer's transportation scenario.

Can convey a variety of materials: In addition to conveying corn, it can also convey a variety of granular materials such as wheat, soybeans, and grains.

Easy to control: Equipped with a PLC automatic control system, the conveyor can be remotely controlled when conveying corn.

Flexibility: It can be transported horizontally, inclined or vertically to adapt to different production scenarios and process requirements.

Screw conveyors have a wide range of application scenarios in corn pellet transportation, including but not limited to the following aspects:

Agricultural processing plants: Screw conveyors can transport corn pellets to processing links such as cleaning, crushing, and grinding.

Corn storage logistics: Mainly used to transport corn pellets from the warehouse to the loading area or from the unloading area to the warehouse.

Food processing plants: In the corn food processing industry, a certain amount of corn pellet raw materials are required. Screw conveyors need to transport corn pellets to different equipment such as mixers, baking equipment, and packaging machines to ensure the normal operation of the production line.

Feed processing plants: In the feed processing industry, screw conveyors are used to transport corn pellets from raw material warehouses to mixers, tablet presses and other equipment.

Screw conveyors have many advantages in conveying granular materials such as corn. They can meet the needs of corn pellet transportation, improve production efficiency, optimize the material transportation process, and save labor costs, making them an indispensable equipment in the grain processing industry.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!