Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

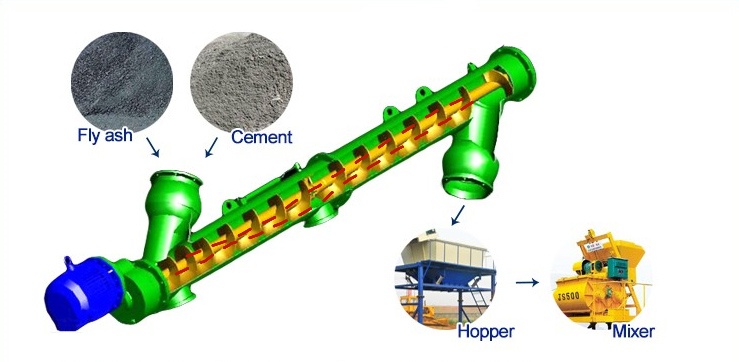

Cement Clinker Screw Conveyor is specially used to convey high-temperature, granular cement clinker in the production line. It adopts high-temperature resistant materials to adapt to the high-temperature characteristics of cement clinker. The closed pipeline avoids the scattering of cement clinker in the conveying project. It is widely used in the production process of cement and building materials.

Cement clinker screw conveyor is an indispensable equipment in the cement production industry. Its advantages are mainly as follows.

High temperature resistance: It adopts high-temperature resistant materials to adapt to the high-temperature characteristics of cement clinker.

Prevent material blockage: The shaftless design can reduce the problem of pipe blockage during transportation.

Prevent cement leakage: The closed design perfectly solves the problem of cement delivery and falling.

Conveying different types of cement: It is suitable for a variety of material states, including dry and wet cement clinker.

Cement clinker screw conveyor is widely used in various links of cement production line.

Clinker bottom conveying: The produced cement clinker is conveyed to the next process through a screw conveyor.

Conveying before clinker mill: The screw conveyor can convey cement clinker to the clinker mill for grinding.

Clinker cooler conveying: The newly produced clinker has a certain temperature and can be quickly transferred to the coolant by the screw conveyor.

The cement clinker screw conveyor pushes the material along the fixed conveying trough through the rotating spiral blade to realize the transportation of cement clinker.

Spiral rotation: The motor drives the spiral shaft to rotate, and the spiral blade rotates accordingly.

Material pushing: The spiral blade pushes the cement clinker from the feed port to the discharge port.

Continuous conveying: The material moves continuously under the push of the spiral blade to complete the conveying process.

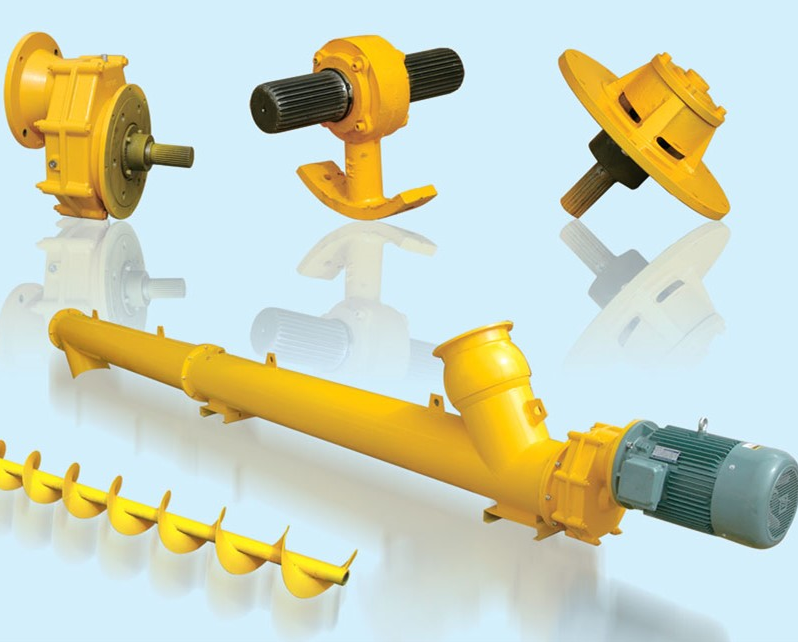

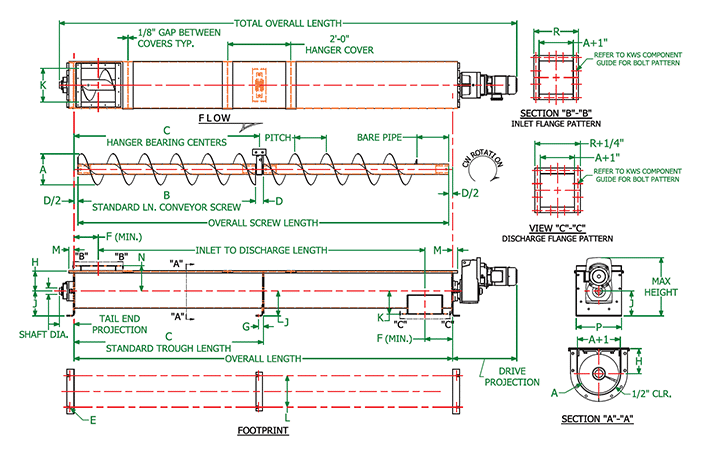

The cement clinker screw conveyor is mainly composed of the following parts

Spiral shaft: The core component, usually made of high-strength steel, with spiral blades welded on the surface.

Spiral blades: Used to push materials, different shapes (such as belts, paddles) can be selected according to the characteristics of the material.

Conveying trough: The shell that holds the material and the screw shaft is usually made of wear-resistant steel plate.

Driving device: It includes a motor and a reducer, which provide power to drive the screw shaft to rotate.

Feed port and discharge port: used for material input and output respectively.

We are a professional manufacturer focusing on the research and development, manufacturing and service of cement clinker screw conveyors. We are committed to serving the cement, building materials, chemical and other industries. With years of industry experience and technical accumulation, we have become one of the leading domestic suppliers of screw conveying equipment. We can provide personalized design according to customer needs to meet the conveying requirements of different working conditions and material characteristics. We provide full-process services from installation and commissioning to after-sales maintenance to ensure that customers have no worries. Choose us, you will get professional technical support, reliable product quality and efficient after-sales service, which will help you improve your production efficiency comprehensively!

Cement clinker screw conveyor is an indispensable equipment in cement production line, with the characteristics of high efficiency, high temperature resistance and wear resistance. Through reasonable selection and maintenance, production efficiency can be significantly improved and equipment service life can be extended. If you need further technical details or application examples, please feel free to let me know!

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!