Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

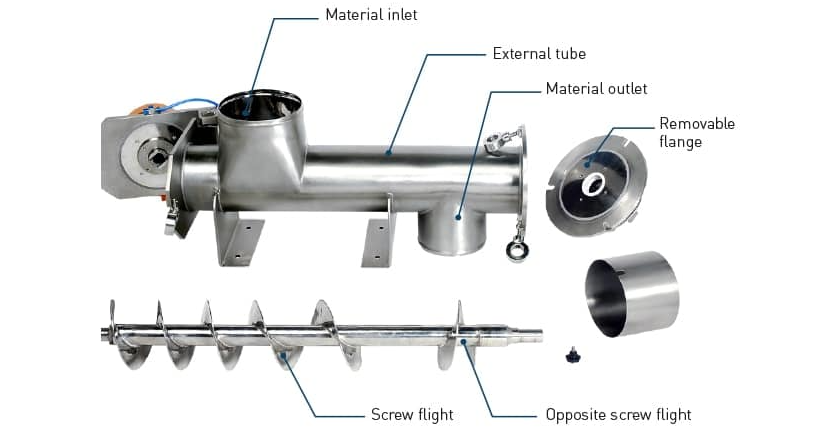

Salt Powder Screw Conveyor is a device used to transport salt powder. It can transport the finished salt powder to the packaging machine and mixer through the screw conveyor. The overall material is closed stainless steel, which meets the hygiene standards and will not cause pollution to the salt during transportation.

Can transport a large amount of salt powder: with different diameters of spiral pipes, suitable for large-scale salt powder transportation

Sealing design: The closed pipeline design can effectively prevent salt powder leakage and reduce pollution waste.

Can transport dry and wet salt powder: with or without shaft and with shaft design, it can adapt to salt powder with different humidity.

304 material: Stainless steel has a certain corrosion resistance and can also ensure the hygiene of salt powder.

The working principle of the salt powder screw conveyor is to use the rotating screw shaft to push the salt powder to move along the axial direction of the casing. When the drive device drives the screw shaft to rotate, the spiral blades and the salt powder generate friction, causing the salt powder to move along the direction of the screw shaft. At the same time, due to the limitation of the casing, the salt powder can only move along the direction of the spiral shaft to achieve transportation.

When choosing equipment suitable for conveying different types of salt powder, many factors need to be considered to ensure efficiency and effect.

Wet salt: high water content, easy to stick, you can choose a screw conveyor with shaftless design and good sealing.

Dry salt: good fluidity, you can use a traditional shafted screw conveyor.

Bag salt powder: when storing and transporting large quantities of salt powder, you can choose a belt conveyor, which can effectively solve the problem of manual handling.

Granular salt powder processing: when it is necessary to quickly convey the salt to a certain height with a crusher, you can choose a bucket elevator for transportation. It has a hopper inside to ensure the consistency of the feed output.

| LS Model | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX Model | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter (mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Pitch (mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Rotating speed (r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Throughput Qp=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| Power Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd 1=30m (KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Rotating speed (r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Throughput QФ=0.33 (m3/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd 1=10m(KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd 1=30m(KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Rotating speed (r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Throughput QФ=0.33(m3/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd 1=10m (KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 133 |

| Power Pd 1=30m (KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Rotating speed (r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Throughput Qφ=0.33 (m3/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| Power Pd 1=10m(KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| Power Pd 1=30m(KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.1 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

Screw conveyors are widely used in the production and processing of salt powder, mainly used in the following links:

Raw material transportation: After salt mining or salt drying in salt fields, the raw salt needs to be transported to the processing plant. Screw conveyors can transport raw salt from the yard or silo to subsequent processing equipment.

Crushing and grinding: After crushing and grinding, raw salt will become fine salt powder. Screw conveyors can transport salt powder from the crusher or grinder to the next process.

Screening and grading: After screening and grading, salt powder will obtain products of different particle sizes. Screw conveyors can transport salt powder to different silos or packaging lines separately.

Mixing and blending: When producing seasoning salt or mixed salt products, salt powders of different ingredients need to be mixed and blended. Screw conveyors can be used to convey various salt powders.

Packaging: In the process of salt product packaging, screw conveyors can be used to transport salt powder from silos or hoppers to packaging machines.

Quantitative feeding of salt powder: Screw conveyors can be equipped with variable speed motors or frequency converters to achieve quantitative feeding of salt powder to meet the requirements of production processes.

In general, screw conveyors play an important role in the production, processing, packaging and recycling of salt powder. It not only improves production efficiency, but also ensures the cleanliness and stability of salt powder during transportation. If you need to transport salt powder, the screw conveyor is undoubtedly your ideal choice!

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!