Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Starch Screw Conveyor is a mechanical device specially used for conveying corn starch, potato starch and cassava starch. It drives the starch to move in a closed pipe or trough through the rotation of the spiral blade to achieve horizontal, inclined or vertical conveying. It has a simple structure and good sealing performance. It will not cause the problem of powder flying during the conveying process. It is an indispensable equipment for powder conveying.

The inclination angle of the starch screw conveyor is an important parameter, which will affect the conveying capacity and efficiency of the conveyor.

Horizontal conveying: The inclination angle is 0 degrees, which is suitable for long-distance conveying.

Inclined conveying: The inclination angle is less than 20 degrees, which is suitable for short-distance conveying or occasions where the height needs to be lifted.

Vertical conveying: The inclination angle is 90 degrees, which is suitable for occasions where the material needs to be lifted vertically.

The following factors need to be considered comprehensively to select a suitable inclination angle:

Material characteristics: Generally speaking, starch with smaller particle size, lower humidity and lower viscosity is suitable for a larger inclination angle.

Conveying distance: The longer the conveying distance, the smaller the inclination angle needs to be selected to reduce the resistance of the material during the conveying process.

Lifting height: If the height of the material needs to be lifted, a larger inclination angle needs to be selected.

Conveying volume: The larger the conveying volume, the larger the inclination angle needs to be selected to improve the conveying efficiency.

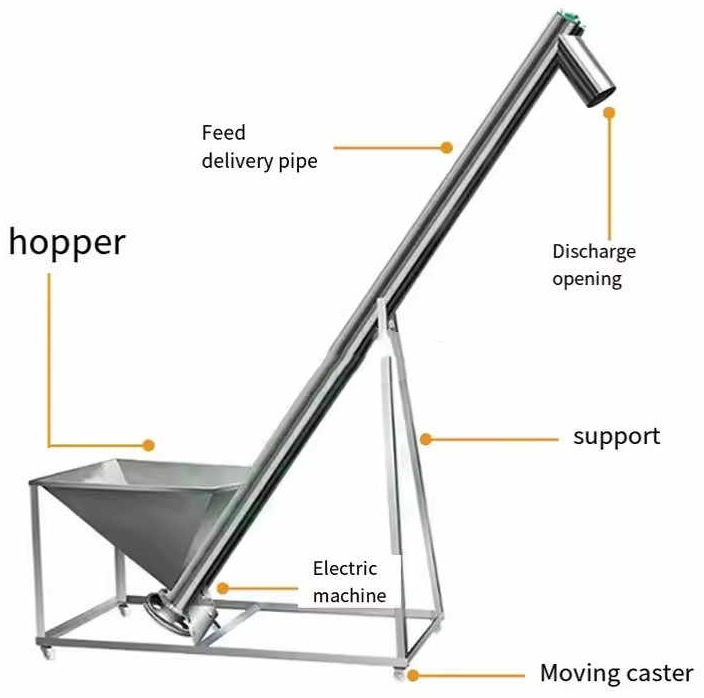

The starch screw conveyor has a simple structure and is made of stainless steel. It is mainly composed of the following components

Spiral blades: Made of stainless steel or carbon steel, it has good wear resistance and corrosion resistance.

Conveying pipe (trough): Usually composed of steel pipe or U-shaped trough to ensure that starch does not leak during transportation.

Driving device: includes motor, reducer and coupling to provide stable power output.

Feed port and discharge port: used for feeding, the discharge port can be equipped with valves or material distribution devices to facilitate the control of starch flow.

The starch screw conveyor drives the spiral shaft to rotate through the motor, and the spiral blade pushes the starch from the feed port to the discharge port. During the conveying process, starch is driven by the propulsion of the spiral blades and its own gravity, thus achieving continuous and uniform conveying.

In the production, processing and transportation of starch, the spiral conveyor has become an ideal choice for starch conveying due to its unique design and performance. The following are the main advantages of starch spiral conveyor in starch conveying

Good sealing to prevent starch dust: The fully enclosed structure is adopted to effectively prevent starch from generating dust during the conveying process.

Meet a variety of starch characteristics: The equipment parameters can be adjusted according to the characteristics of starch (such as particle size, humidity, viscosity) to ensure smooth conveying.

Meet food grade requirements: The equipment is made of stainless steel, with a smooth inner wall and easy to clean, which meets the hygiene standards of the food and pharmaceutical industries.

Easy maintenance and reduced downtime: The spiral conveyor has a simple structure, is easy to disassemble and clean, and has low maintenance costs.

Multiple installation methods to adapt to different scenarios: Supports horizontal, inclined or vertical installation to adapt to different production scenarios.

Starch screw conveyor is widely used in starch production and processing, mainly in the following aspects

1. Starch extraction: In the process of starch extraction, screw conveyor can be used to convey starch extracted from potatoes and cassava.

2. Starch processing: The dried starch needs to be conveyed and packaged. The screw conveyor can be used to convey the dried starch to the packaging machine or storage bin.

3. Starch sugar production: Starch sugar is a variety of sugar products made from starch. In the process of starch sugar production, screw conveyor can be used to convey starch slurry, glucose syrup and other materials.

The clay shaftless screw conveyor has become an ideal equipment for handling high viscosity clay due to its non-blocking, strong conveying capacity and good sealing. It plays an important role in industries such as ceramics, construction, environmental protection, chemicals and agriculture, and can efficiently and reliably complete the conveying task of clay. When selecting, it is necessary to select the appropriate equipment specifications and materials according to the characteristics of clay (such as viscosity, humidity, particle size) and process requirements.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!