Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Calcium Carbonate Screw Conveyor is a mechanical device used to convey calcium carbonate powder or particles. Its conveying process has high requirements for the sealing, wear resistance and stability of the equipment. The screw conveyor pushes calcium carbonate to move in a closed pipe or tank through the rotation of the spiral blade to achieve horizontal, inclined or vertical conveying. It is generally used in the food additive and pharmaceutical industries.

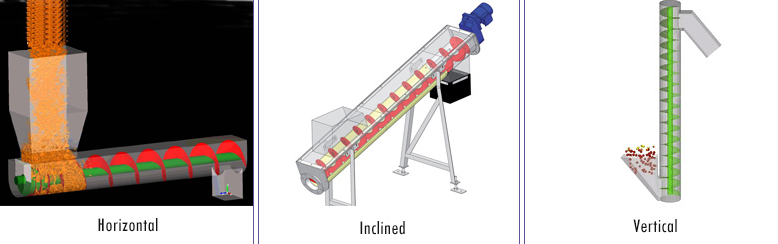

Calcium carbonate screw conveyors can be divided into horizontal screw conveyors, inclined screw conveyors and vertical screw conveyors according to the installation angle and conveying direction. Each type of conveyor has its unique application scenarios and advantages.

1. Horizontal screw conveyor: suitable for conveying calcium carbonate powder or particles with good fluidity, and can convey calcium carbonate from the raw material warehouse to the production equipment. Used for short-distance horizontal transfer.

2. Inclined screw conveyor 0°~45°: can achieve inclined conveying within a certain angle range to save space. Conveying calcium carbonate from the ground to higher equipment or storage silos can achieve material lifting and transfer in production lines with limited space.

3. Vertical screw conveyor90°:The conveying height is large, suitable for long-distance vertical lifting. The fluidity requirements for calcium carbonate are high, and it is necessary to ensure that the material is not easy to agglomerate or adhere. Lift calcium carbonate vertically from the ground to a high-level storage silo or equipment.

Choose according to the conveying distance:

Short-distance conveying: Choose a horizontal screw conveyor.

Medium-distance conveying: Choose an inclined screw conveyor (angle not exceeding 30°).

Long-distance vertical conveying: Choose a vertical screw conveyor.

Choose according to material characteristics:

Calcium carbonate powder with good fluidity: suitable for horizontal or inclined conveyors.

Calcium carbonate particles with poor fluidity: It is necessary to choose a large-angle or vertical conveyor, and equip it with a vibration device to prevent clogging.

Choose according to space layout:

Spacious space: give priority to horizontal or inclined conveyors.

Limited space: give priority to vertical conveyors.

In the production, processing and transportation of calcium carbonate, the screw conveyor has become an ideal choice for calcium carbonate transportation due to its unique design and performance.

1. Improve production efficiency: The scientific spiral blade design can quickly and evenly convey calcium carbonate to meet the needs of large-scale continuous production.

2. Prevent calcium carbonate dust: Calcium carbonate particles are small and easily dispersed during transportation, causing material waste and environmental pollution. The sealing design not only reduces the loss of calcium carbonate, but also improves the working environment.

3. Strong wear resistance and extended equipment life: Calcium carbonate has a certain abrasiveness, and ordinary equipment is prone to wear and damage. The use of wear-resistant materials extends the service life of the equipment and reduces maintenance costs.

4. Strong adaptability to meet a variety of calcium carbonate characteristics: The equipment parameters can be adjusted according to the characteristics of calcium carbonate (such as particle size, humidity, viscosity) to ensure smooth transportation. Material residue.

5. Easy maintenance and reduced downtime: Calcium carbonate is easy to remain in the equipment. Regular cleaning and maintenance are the key to ensure the normal operation of the equipment. The simple maintenance design of the screw conveyor reduces downtime and improves production efficiency.

The calcium carbonate screw conveyor is a device that uses the rotation of spiral blades to transport calcium carbonate materials from one location to another. When the spiral blade rotates, calcium carbonate gradually moves toward the outlet along the conveying pipeline under the force of gravity and the push of the spiral blade, and is finally transported to the designated location.

Calcium carbonate screw conveyors play an important role in multiple industries and scenarios, especially in environments where efficient conveying of calcium carbonate is required.

Cement plant: In the cement production process, screw conveyors can transfer limestone and other raw materials to the grinding system.

Premixed mortar: In mortar production, screw conveyors transport calcium carbonate to the mixer for mixing with other ingredients.

Plastic processing: Screw conveyors are used to convey calcium carbonate as a filler to a mixer to provide strength and wear resistance for plastic products.

Paint manufacturing: Calcium carbonate is an important filler, and screw conveyors can convey calcium carbonate raw materials to a mixer for addition and mixing.

Calcium carbonate screw conveyors play an important role in the production, processing, and packaging of calcium carbonate. It not only improves production efficiency, but also ensures the cleanliness and stability of calcium carbonate during the conveying process.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!