Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

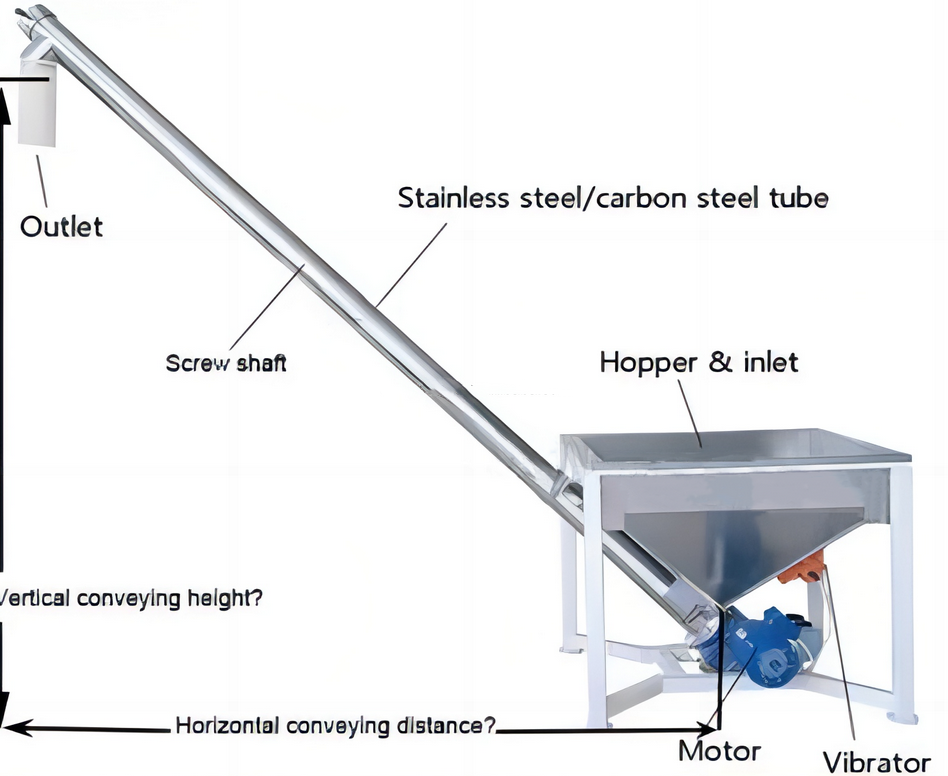

Ranch Series Auger Feeder utilizes innovative auger conveying technology, equipped with wear-resistant spiral blades and a removable chassis, allowing for flexible transfer positions and adapting to different application scenarios. Auger Feeder supports rapid transfer operations. Available in 304 stainless steel or carbon steel, it meets various hygiene standards. Compared to traditional transfer methods, it consumes 60% less energy. Customizable to your specific needs, we can tailor the right conveyor system to your ranch, ensuring a seamless transfer process.

Our Farm Series spiral feeders offer three popular hopper designs: round, square, and conical, fully meeting the needs of different feed characteristics and farm scenarios. The round hopper is sealed and dustproof, the square hopper has a large capacity, and the conical hopper prevents bridging, making it ideal for handling sticky materials.

Round hoppers: With their symmetrical structure and evenly distributed load, they are suitable for conveying free-flowing granular or powdered materials such as feed and grain. They also offer excellent sealing properties, reducing dust spillage.

Square hoppers: With their large capacity, they easily interface with linear conveying equipment like conveyors and are well-suited for space-constrained pastures. They are primarily used for storing and conveying bulky, lightweight materials such as grass and straw.

Conical hoppers: With their tapered bottom design, they guide and concentrate material flow, preventing bridging and residue buildup. They are suitable for handling sticky, easily agglomerated materials such as wet feed and additives.

The Ranch Series Auger Feeder features fast conveying, stability and durability, and a unique sealing design that effectively prevents dust and moisture. Combined with a customized hopper and variable frequency speed regulation function, it significantly improves feeding efficiency and reduces operating costs!

Flexible mobility: equipped with heavy-duty universal wheels or traction hooks, supports fast transfer, and is suitable for rotation of multiple livestock houses.

Fast delivery: delivery capacity 1-10t/h, delivery distance 5-20 meters (customizable), meeting the needs of large, medium and small ranches.

Low loss design: special treatment of spiral blades and pipe body to avoid feed crushing (crushing rate <1%).

Multi-material adaptation: granular feed, powdered premix, and silage can all be stably transported.

Energy-saving design: motor power 2.2-15kW, energy consumption is 60% lower than traditional manual feeding.

The Ranch Series Auger Feeder is designed with mobility, conveying accuracy and environmental adaptability as the core design concept. Each component works together to achieve automatic and intelligent feed delivery.

Universal wheel: The front wheel is a universal wheel (with brake), with a steering angle of 360° and a minimum turning radius of ≤1.2 meters, suitable for the narrow passage of the cowshed.

Spiral component: The spiral blades in contact with the feed are made of 304 stainless steel to reduce feed residue and adhesion.

Main shaft: 40-60mm diameter stainless steel shaft, with deep groove ball bearings at both ends, adjustable speed of 50-150rpm, and the conveying volume is controlled by the frequency converter.

Conveying pipe: 304 stainless steel pipe, inner diameter 150-300mm, customizable length.

Storage hopper: Conventional 100-500L, inverted cone design (cone angle 60°), ensuring smooth self-flow of feed, suitable for single feeding needs of small ranches.

Main drive motor: three-phase asynchronous motor (power 1.5-3kW), IP54 protection level, suitable for humid ranch environment;

Mobile drive motor: DC brushless motor (power 0.75-1.5kW), 20% more efficient than traditional brushed motor.

The working process of the ranch series spiral feeder is as follows: Before starting, push the equipment to the designated feeding point through the mobile chassis, and the electric type can automatically drive and position. The operator sets the feeding amount on the control screen. After the feed in the hopper is broken by the vibration motor, the quantitative gate controls the flow rate and falls into the conveying pipe. The motor drives the spiral blade to rotate, lifts the feed along the pipeline and pushes it to the discharge port, and evenly puts it into the feeding trough. During the conveying process, the observation window can monitor the feed status, and the material level sensor monitors the inventory in real time. When it is insufficient, an alarm will be issued to prompt refilling. After the operation is completed, the residual feed is cleaned through the feed cleaning port, and the mobile chassis is folded to quickly transfer to the next feeding point. The whole process is efficient and coherent, and it is adapted to the feeding needs of multiple scenarios on the ranch.

The ranch series spiral feeder is widely used in the field of animal husbandry and related scenarios due to its flexible movement and precise transportation.

Large-scale dairy farms: It can flexibly shuttle between different cow sheds, milking halls and feed warehouses, and accurately deliver silage and mixed concentrate to each feeding trough to meet the feeding needs of dairy cows in different groups.

Modern pig farms: Provide customized feed for piglets and fattening pigs in different areas such as nurseries and fattening houses to prevent feed from spilling and wasting, and keep the pig house environment clean.

Poultry farms: In poultry breeding sheds, quickly deliver granular feed and powdered nutritional additives to the automatic feeding system to ensure that the feed is fresh and hygienic.

Special animal breeding: For special animal breeding sites such as alpacas and deer, the conveying volume can be flexibly adjusted according to the habits and nutritional needs of animals to achieve personalized and precise feeding.

Feed processing workshop: In the feed production process, the crushed and mixed materials are transported from the processing equipment to the storage bin or transport vehicle to complete the material transfer and distribution.

|

Comparison Dimension |

Ranch Series Screw Feeder |

Traditional Feeding Methods (e.g., Manual Feeding, Fixed Trough Feeding) |

|

Feeding Efficiency |

Automated conveying; one device covers multiple areas with 3-5 tons/hour capacity, reducing manual round-trip time. |

Manual handling or fixed trough requires point-by-point feeding, with low efficiency and high labor demand for large-scale ranches. |

|

Flexibility and Mobility |

Automated conveying; one device covers multiple areas with 3-5 tons/hour capacity, reducing manual round-trip time. |

Fixed trough feeding has stationary positions; manual feeding relies on transport tools, showing poor flexibility. |

|

Environmental Adaptability |

Fully enclosed pipeline design, rainproof and pollution-proof, operable in open-air or humid sheds. |

Open-air feeding is vulnerable to weather, with feed prone to mildew; open troughs are difficult to clean. |

|

Data-driven Management |

Control panel records feeding volume, frequency, etc., supporting integration with ranch management systems for breeding data traceability. |

No data recording function; unable to monitor feed consumption and its correlation with animal growth accurately. |

|

Application Scenarios |

Large-scale ranches, feed processing workshops, multi-variety group breeding scenarios, especially suitable for frequent transfer or precision feeding needs. |

Small-scale farms or traditional free-range modes with low requirements for efficiency and precision. |

It can convey pellet feeds such as corn and soybean meal, premixed powder, mineral powders, and long-fiber grass such as silage and hay.

Pellet feed conveying: This series of equipment is specially designed for pellet feed, and can convey cattle and sheep pellets, poultry compound feed and fish feed (particle size 2-8mm) at high speed. The standard shafted spiral structure ensures a stable conveying volume of 1-5t/h, and the special low-crushing design makes the feed breakage rate less than 1%. The carbon steel economic model meets the needs of conventional ranches, and can be equipped with variable frequency speed regulation to achieve precise feeding.

Powdered premix conveying method: For fine powders such as vitamin premixes and mineral additives, a fully enclosed shaftless spiral design is adopted, and the 304 stainless steel material meets food hygiene standards.

Silage handling: The large pitch shaftless spiral model (blade spacing ≥ 300mm) is specially developed for fiber materials such as corn silage and alfalfa segments, which completely solves the problem of winding and blocking.

Mixed wet material conveying: For sticky materials such as fermented feed and molasses mixture, a stainless steel quick-release model with polished inner wall is selected. The anti-stick coating is combined with a high-pressure cleaning interface to ensure that the material does not remain.

Select the conveying capacity according to the scale of the ranch: different types of conveying equipment are used for 100 heads and more than 1,000 heads.

Small ranches (with less than 100 heads in stock): It is recommended to use a mobile spiral feeder with a standard conveying capacity of 1-3 tons/hour, equipped with a manual or electric mobile chassis (8 hours of battery life), which can flexibly cover 3-5 feeding points.

Large ranches (with more than 1,000 heads): It is recommended to adopt a fixed + mobile combination solution, deploy a 5-10 t/h fixed spiral system on the main conveyor line (such as from the feed tower to the main channel), and use a mobile feed distributor (with a conveying capacity of 3-5 t/h) to achieve accurate feeding at the end.

Multi-variety grouping farming scenario: Optional dual-hopper intelligent switching model, equipped with two independent storage hoppers (capacity of 200L each), automatically switch to convey different formula feeds through PLC preset programs.

Extreme climate areas (such as below -10℃): It is recommended to install an electric heating and insulation system, wrap the heating belt (power 0.5kW/m) on the outer wall of the conveying pipe, and use a polyurethane insulation layer (thickness 50mm) to ensure that the feed does not freeze in a low temperature environment.

The Ranch Series Auger Feeder provides efficient and stable feed management solutions. Available with round, square, and conical hoppers, it meets the needs of various farming scenarios.

Large dairy farms: To address the low efficiency and inaccurate feed ratios of traditional manual feeding, a stainless steel screw feeder equipped with a conical hopper and a variable frequency drive system was used for automatic feeding.

Sheep farms in high-humidity areas: Faced with the challenges of handling easily clumped wet feed and preventing equipment corrosion, a customized 304 stainless steel screw feeder was developed. The hopper features a vibrating arch-breaking device, a sealed structure to prevent moisture erosion, and a special coating on the spiral blades to reduce sticking.

Intensive chicken houses: Due to limited space, compact equipment is required for automatic feeding. A vertically mounted square hopper screw feeder was selected to save space. Connected to a PLC control system and linked to sensors, it delivers feed at fixed times and in fixed quantities based on flock size.

The price of ranch spiral feeders is divided into three ranges according to the configuration differences: the economical carbon steel model (1-3t/h) is suitable for small and medium-sized ranches; the 304 stainless steel model is 30%-50% more expensive and is dedicated to premixes and wet feeds; the customized model (shaftless/frequency conversion model) requires a separate quotation. The mobile type is 15%-20% more expensive than the fixed type. We provide free selection services to ensure the best cost-effective solution. If you need it, please feel free to contact us!

The ranch series spiral feeder has become an important part of modern animal husbandry feed management with its advantages of precision, high speed, sturdiness and durability. And its innovative "mobile" feature gives the equipment unprecedented flexibility and adaptability, which can better meet the complex and changing feeding needs of ranches. It will help farmers achieve smarter, more convenient and more economical feed management, thereby improving overall breeding benefits.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!