Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Food Grade Conveyor Belts for Food Handling and Processing adopts highly elastic PU/PVC/silicone materials, are non-toxic and odorless, oil-resistant and temperature-resistant (-40℃ to +220℃), and are suitable for baking, meat, fruits and vegetables and other processing scenarios. Food Grade Belt Conveyor has optional thickness of 1.5-10mm and customized width of 100-2000mm. Anti-skid patterns, guide strips or baffles can be added on the surface to ensure stable conveying. Tear resistance ≥15MPa, good wear resistance, easy to clean, support dry and wet use, effectively improve production efficiency. Anti-mildew and antibacterial design, suitable for environments with high hygiene standards, such as cold chain, packaging, sorting, etc.

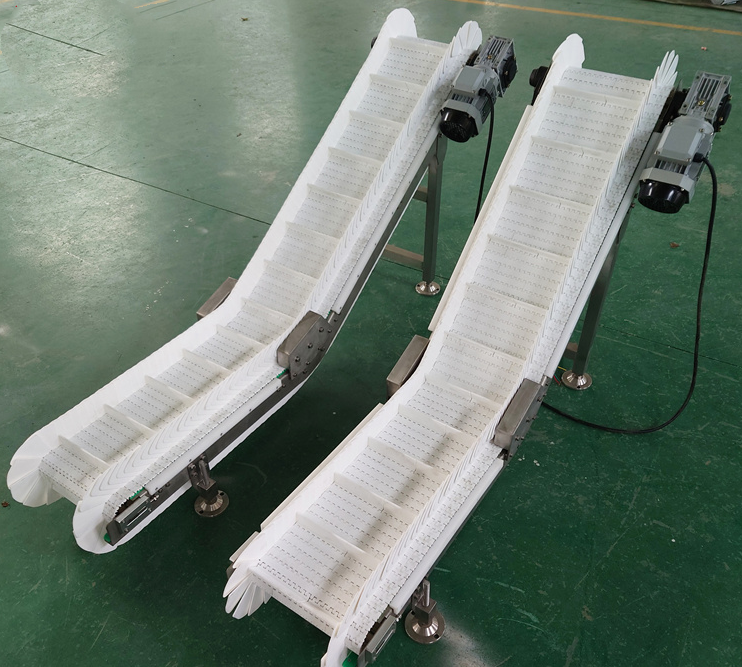

Food-grade conveyor belts used for food handling and processing can be categorized by conveying angle into horizontal and inclined types. Horizontal conveyors are suitable for flat surfaces, while inclined conveyors are suitable for climbing slopes.

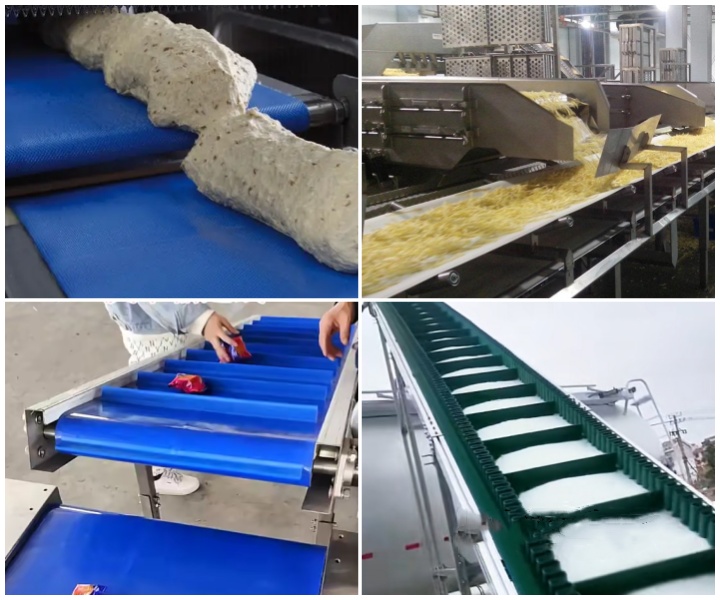

Horizontal food-grade conveyor belts: centered around horizontal conveying, are suitable for sorting, packaging, and assembly. They utilize standard PU, PVC, or silicone belts, with anti-slip grooves or sidewalls to prevent material slippage. They are widely used in conveying baked goods such as bread and biscuits, in meat and seafood processing lines, and in fruit and vegetable sorting and packaging.

Inclined food-grade conveyor belts:adjustable from 10° to 30°, allow for both climbing and descending conveyance. They feature an anti-slip design to ensure stable conveyance of wet materials, and optional hollow belts facilitate drainage. They are suitable for conveying washed fruits and vegetables uphill, canning and bagging sauces and granular foods, and transferring frozen foods between upper and lower levels.

Food-grade conveyor belts have significant advantages in food processing. The materials meet food standards, are safe and non-toxic, resistant to high and low temperatures, oil and water, easy to clean, and can be adapted to horizontal and inclined scenarios.

Safety and hygiene: Food-grade conveyor belts are made of food-grade silicone, polyurethane, polyethylene, etc. These materials are non-toxic and tasteless, do not contain harmful chemicals, and will not react chemically with food or release harmful substances.

Durable and reliable: Conveyor belts made of polyurethane have excellent wear resistance and can withstand the friction of food particles, packaging containers, etc., and their service life is 2-3 times longer than that of ordinary conveyor belts; silicone conveyor belts have excellent high and low temperature resistance and can work stably in an environment of -60℃-200℃.

Meet diversified production: Food processing covers baking, meat processing, fruit and vegetable sorting, beverage filling and other sub-segments, and different production links have different requirements for conveyor belts. Food-grade conveyor belts provide a variety of types and customized services to meet the diverse needs of customers.

Energy saving and noise reduction: Food-grade conveyor belts use lightweight design and low friction coefficient materials, which require less power during operation and can reduce energy consumption by 15%-20% compared to traditional conveyor belts.

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 |

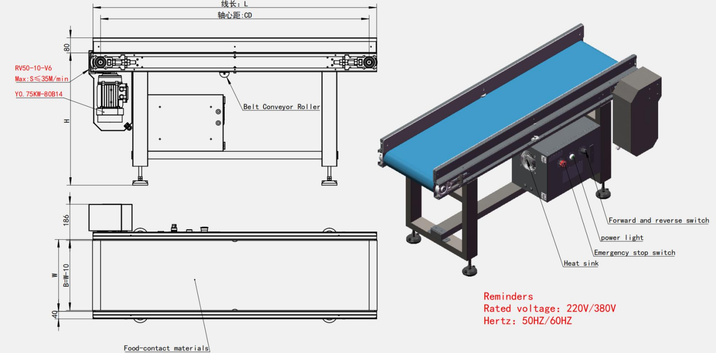

The working principle of food grade conveyor belts is similar to that of ordinary conveyor belts. It mainly relies on the driving device (such as motor, reducer) to drive the transmission roller to rotate, and the friction makes the conveyor belt circulate to realize the transportation of materials.

From high temperature baking to low temperature freezing, from meat cutting to fruit and vegetable sorting, food grade conveyor belts accurately match the needs of food processing in all scenarios with safe materials, customized design and excellent performance.

Baking industry: In bread and biscuit production lines, food grade silicone conveyor belts can withstand high temperatures above 200℃, suitable for baking links, can maintain stable performance in high temperature environments, and the surface is smooth and non-sticky, which is convenient for product demolding and transmission.

Meat processing industry: During meat cutting and sorting, the cut-resistant and easy-to-clean food grade conveyor belts can resist accidental scratches by knives and reduce the risk of damage.

Fruit and vegetable processing industry: In the process of washing, sorting and packaging fruits and vegetables, mesh-belt food-grade conveyor belts have good air permeability, which is convenient for water to drain and improves washing efficiency; conveyor belts with skirts and baffles can realize inclined conveying of fruits and vegetables to avoid slipping.

Beverage filling industry: In the process of conveying, filling and labeling beverage bottles, food-grade conveyor belts are accurately positioned and can be precisely matched with filling equipment, labeling machines, etc.; its anti-static design can prevent beverage bottles from absorbing dust due to static electricity.

Professional food-grade conveyor belts are far superior to ordinary conveyor belts in terms of safety compliance, durability and food adaptability due to certified materials, aseptic design and strict hygiene standards.

Material standards: Food-grade conveyor belts are made of food-grade silicone, polyurethane (PU), polyethylene (PE) and other materials that meet international authoritative certifications such as FDA and NSF, eliminating harmful substances from the source, ensuring that they are non-toxic and tasteless, and will not react chemically with food, thus building a solid line of defense for food safety. In contrast, ordinary conveyor belts are mostly made of ordinary rubber, plastic and other materials, which may contain harmful substances such as plasticizers and heavy metals. Once in contact with food, it is very easy to cause contamination.

Hygienic performance: Food-grade conveyor belts have the advantage of smooth and flat surfaces. The characteristics of no pores and cracks make it difficult to leave food residues; some products also have antimicrobial properties, which can effectively inhibit the growth of bacteria. On the other hand, ordinary conveyor belts have rough surfaces and pores, and dirt and bacteria are easily retained in them. It is difficult to clean and it is difficult to achieve the hygienic level required by food production.

Environmental adaptability: Food-grade conveyor belts have excellent environmental adaptability and have excellent properties such as high temperature resistance, low temperature resistance, acid and alkali resistance, and grease resistance. Whether it is a high temperature environment during baking or a low temperature condition in the freezing process, it can operate stably. When ordinary conveyor belts face high temperature, low temperature or corrosive environment, the material is prone to aging and deformation, which not only affects the normal use of the conveyor belt.

Durability: In order to cope with the high load and high frequency operation in the food processing process, food-grade conveyor belts have significantly enhanced wear resistance and fatigue resistance by means of edge reinforcement, improved joint technology, and the use of wear-resistant materials. Ordinary conveyor belts have poor wear resistance and fatigue resistance due to the limitations of materials and processes, and are very easy to be damaged under complex food processing conditions.

Degree of customization: The food processing industry has diverse needs. Food-grade conveyor belts fully take this feature into account, provide a rich selection of types, and can customize the width, length, color, surface texture, etc. of the conveyor belt according to customer needs, accurately adapting to various food processing scenarios. Ordinary conveyor belts are limited to fixed types and specifications, with a low degree of customization, and it is difficult to meet the special requirements of the food industry for equipment diversification and refinement.

Food-grade conveyor belts can transport a variety of food types, including granular candies and nuts, powdered flour and milk powder, sticky/wet dough and jam, as well as slices and strips of potato chips and bacon, etc., adapting to the transportation needs of different forms of food.

Granular foods: including candies, nuts, grains, frozen vegetables, beans, etc., require conveyor belts with non-slip surfaces or sidewalls to prevent rolling. They are suitable for horizontal or slightly inclined conveying at a degree of ≤15° to ensure stable material transmission.

Powder and powdered foods: such as flour, milk powder, seasonings, and protein powder. The conveyor belt must adopt a fully enclosed structure to prevent dust from flying, and the surface must be smooth for easy cleaning without residue, in line with hygiene requirements.

For sticky/wet foods :such as dough, cheese, minced meat, and jam, the conveyor belt should have a Teflon or silicone anti-stick coating, a tiltable design, and a self-cleaning scraper to reduce material adhesion and maintain conveying efficiency.

For sheet/strip foods:including potato chips, bacon, seaweed, and noodles, the conveyor belt needs a low-friction surface to reduce breakage and precise speed regulation to avoid accumulation, adapting to the shape protection requirements of this type of food.

In response to the strict requirements of the food industry such as high temperature, high humidity, and hygiene, we provide high-performance food-grade conveyor, aseptic design, and customized functions to provide safe and fast conveying solutions for baking, meat, fruits and vegetables and other scenarios.

|

Industry Scenario |

Customized Solution |

Key Features |

|

Baking |

High-temperature silicone conveyor belt |

Resists up to 220℃, non-stick surface for easy cleaning, residue-free transport of pastries and bread |

|

Meat Processing |

Antimicrobial PU/PVC conveyor belt |

Oil-resistant, cut-resistant, compliant with HACCP standards, suitable for meat cutting and packaging lines. |

|

Fruit & Vegetable Sorting |

Soft anti-scratch PE conveyor belt |

Low-friction design protects produce skin, minimizes damage during sorting and handling. |

|

Cold Chain Logistics |

Low-temperature resistant TPU conveyor belt |

Withstands -40℃, non-slip and freeze-resistant, ensures stable transport of frozen foods. |

|

Packaging |

Precision timing conveyor bel |

synchronous high-speed cartoning and sealing, prevents offset during packaging. |

The core reasons why food companies must choose food-grade conveyor belts can be summarized as follows.

Ensure food safety: Food-grade conveyor belts are an important line of defense for food safety. The total number of colonies at the seams of ordinary belts can reach 10⁴ CFU/cm², while food-grade conveyor belts can control the total number of colonies to <10² CFU/cm² with their seamless design.

Optimize production efficiency: Food-grade conveyor belts significantly improve production efficiency and reduce costs. It supports CIP cleaning and can be cleaned within 15 minutes, which saves a lot of time compared to ordinary belts that require manual brushing for 1-2 hours/time; the anti-sticking design reduces the material residue rate from 15% to <1%.

Adapt to complex working conditions: Food processing has complex working conditions such as high temperature, low temperature, and high acid. Food-grade conveyor belts have excellent environmental adaptability. In a high-temperature frying environment of 150℃, silicone belts can remain unchanged, while ordinary PVC belts will soften and release toxins; in the -30℃ quick freezing stage, the cold-resistant TPU material resists brittle cracking, while ordinary rubber belts are prone to breakage and cause downtime.

Reduce overall costs: The average service life of food-grade PU belts is 3-5 years, while ordinary PVC belts are only 6-12 months. Taking a 10-meter production line as an example, although the initial investment of a food-grade conveyor belt is 50,000 yuan higher than that of an ordinary belt, it does not need to be replaced within 3 years, and saves 36,000 yuan in cleaning agent costs each year, and the total cost in 3 years is only 150,000 yuan; ordinary belts need to be replaced twice in 3 years, with a total cost of up to 300,000 yuan, so choosing a food-grade conveyor belt is more economical.

When choosing a food-grade conveyor belt for food handling and processing, the price is usually affected by multiple factors, including materials, design, specifications, and customization requirements. Food-grade conveyor belts are generally made of high-quality materials that meet hygiene standards, such as PVC or PU, which ensure safety and durability. Customized options, such as conveyor belts designed according to specific process requirements, usually add additional costs. If you are interested, please feel free to contact us for detailed quotes and solutions!

Food-grade conveyor belts are key equipment to ensure the efficiency and safety of food handling and processing. We can provide targeted solutions based on the specific needs of customers, which can help companies stand out in the fiercely competitive market. Choosing the right food-grade conveyor belt can not only improve production efficiency, but also ensure product quality, achieving a win-win situation of customer satisfaction and corporate benefits.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!