Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Food Grade Belt Conveyor uses a belt to transport food from the feed port to the designated location. Generally, food-grade belts are used to meet hygiene standards.

Belt material: food-grade PVC, PU

Belt width: 300-1500mm

Speed: 0.8-4.0m/s

Conveying capacity: 28-800m3/h

Conveying length: 6 meters

Conveying angle: 0-90°

Frame material: SUS304 stainless steel

Weight: 300 kg

Application: Used in the food industry to transport various foods, such as grains, fruits, vegetables, meat, baked goods, candy, bread, pastries, potato chips, biscuits, etc.

Promise: Free delivery/5-day delivery/30-day return/customization support

Food Grade Belt Conveyor is a high-sanitation conveying equipment designed for the food processing industry. The core components are made of materials that meet international food contact material certifications such as FDA and EU 10/2011. They are oil-resistant and temperature-resistant (-20℃ to 120℃), and can withstand high-pressure washing and steam sterilization. It can convey production lines for candies, cakes, meat and vegetables, and is particularly suitable for candy chocolate coating, baked food cooling, fresh meat cutting and vegetable sorting with high sanitation requirements.

Food Grade Belt Conveyor uses belts that meet FDA/USDA standards to ensure hygienic material transportation and prevent contamination.

Meeting hygiene standards: The conveyor belt is made of food grade PVC, PU and other materials, which are non-toxic and harmless and easy to clean.

Corrosion resistance and high temperature resistance: It can withstand the corrosion of various cleaning agents and disinfectants, as well as the transportation of high-temperature materials.

There is a certain friction: The conveyor belt produces a certain amount of friction particles with the product during transportation, which reduces the situation of material blockage.

Customizable: Conveyors of various specifications and shapes can be customized according to different production lines and material characteristics.

There are many types of food grade belt conveyors, and each type has its unique advantages and scope of application.

PVC belt conveyor: It has good wear resistance and chemical resistance, suitable for conveying, such as bread, vegetables, etc.

PU belt conveyor: strong wear resistance, long service life, certain tensile resistance, can be selected for conveying chicken breast, steak and other meat.

Silicone belt conveyor: It has certain high temperature resistance, oil resistance, acid and alkali resistance, and can convey baked bread, pastries, etc.

Mesh belt conveyor: It adopts metal mesh belt, which has the characteristics of ventilation and air permeability, easy to clean and disinfect, and can be used in food processing links that require ventilation and drainage, such as fried chicken, French fries, etc.

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 |

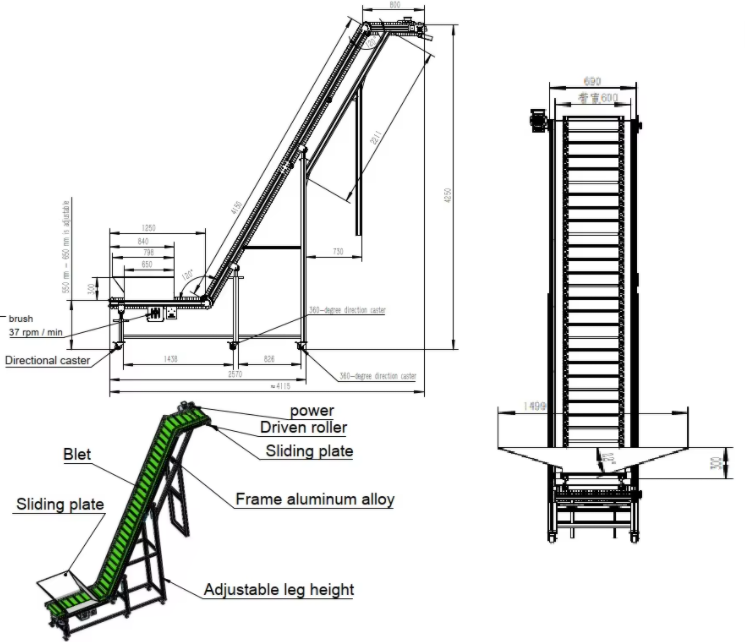

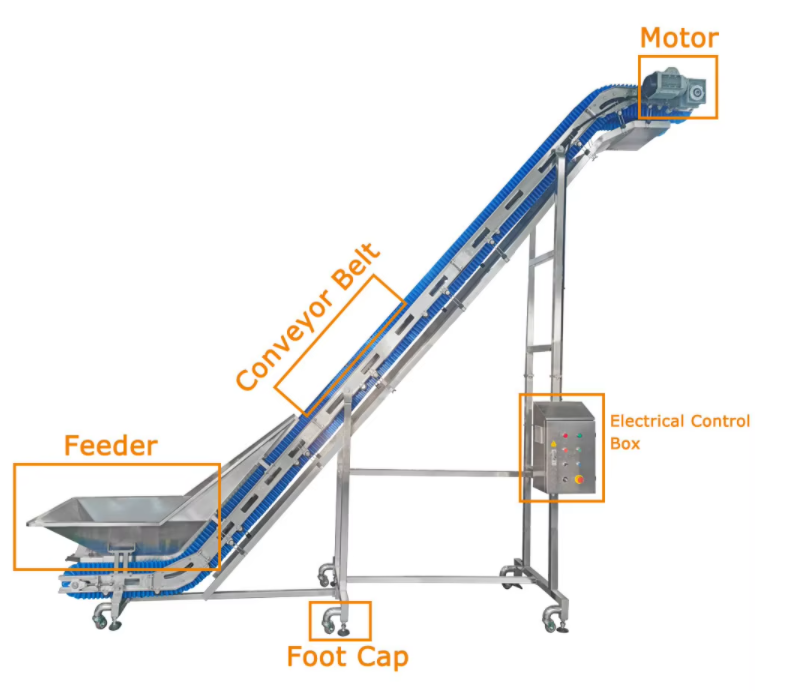

The structure of the food-grade belt conveyor is usually simple, mainly including the following key components:

Conveyor belt: The conveyor belt is the belt on the conveyor, usually made of PVC, PU, silicone and other materials, which meets the food hygiene standards.

Drive device: The drive device is usually composed of a motor, a reducer and a transmission device, which is used to drive the belt for transportation.

Support structure: The support structure is the structure of the conveyor, which is used to support the transportation of food and fix the belt and other components.

Guide device: The guide device guides the direction of food during transportation.

Tension device: The tension device can adjust and maintain the tension of the belt to ensure that the belt maintains proper tension during operation and reduce the relaxation and deviation of the belt.

The food-grade belt conveyor drives the belt through the motor, the support structure firmly supports, the guide device guides the transportation direction of the food, the cleaning device maintains hygiene, the tension device adjusts the tension, and finally transports the food from the starting point to the end point. The safety device ensures safe operation, and together ensures that the food is efficiently and safely transported on the production line.

Food-grade belt conveyors are equipment used for material transportation in the food industry. Depending on the material, the application scenarios vary.

Rubber material: Suitable for various types of baked food factories, such as bread, biscuits, candies, meat processing plants, etc. It can withstand certain temperature changes and has good flexibility and wear resistance. It can adapt to foods of different shapes and weights and can meet the frequent transportation needs during meat processing.

PVC material: Widely used in fruit and vegetable processing companies, it can be used for fruit grading, transportation after washing, and sorting and pre-packaging transportation of vegetables. PVC material is corrosion-resistant and can adapt to the humid environment during fruit and vegetable processing. It has a smooth surface and will not damage the skin of fruits and vegetables.

PU material: In dairy factories, it is often used for pre-filling transportation of liquid dairy products such as milk and yogurt. PU material has good water resistance and chemical resistance, which can prevent dairy products from corroding the belt. It can still maintain good flexibility and strength in low temperature environments, ensuring that quick-frozen foods are not damaged during transportation.

Teflon material: Commonly found in some high-end food processing factories, such as chocolate factories. Teflon material is non-sticky and can prevent chocolate from adhering to the belt. In some food factories that require high-temperature processing, such as fried food factories, Teflon belts can withstand higher temperatures. Its high temperature resistance and non-stickiness make it an ideal choice for high-temperature food transportation.

When choosing a food-grade belt conveyor, you can choose a conveyor that suits you based on the characteristics and shape of the product.

Liquid flowing food: You can choose a conveyor with an anti-drip design, such as a mesh belt conveyor, to prevent food from overflowing during transportation.

Bulk food: Consider choosing a conveyor with a skirt design and an anti-slip design to ensure that the food is transported stably without scattering.

Fragile food: Choose a conveyor with a softer surface and buffering performance, such as a PU belt conveyor.

High temperature or low temperature food: Choose a silicone belt conveyor made of high temperature or low temperature resistant materials to ensure the quality of transportation and food safety.

Food with sauce and grease on the surface: Choose a PVC belt conveyor made of easy-to-clean material, which not only ensures the safety of the food but also facilitates cleaning.

In the horizontal transportation scenario, we have customers from different industries. The following is the on-site feedback of the solutions configured for them.

PVC quick-frozen dumplings processing plant: Large quick-frozen food companies need to transport the formed dumplings from the packaging machine to the quick-freezing tunnel. The transportation process is required to be hygienic, non-sticky and easy to clean. PVC food-grade belts (5mm thickness, white anti-slip surface) are used for horizontal transportation. The length is 8 meters and the width is 600mm. 3,000 dumplings are transported per hour. The anti-stick design of the belt surface prevents the dumplings from being damaged. The PVC material is resistant to low temperatures (-30℃) and is suitable for the pre-cooling workshop environment.

Bottled beverage labeling horizontal assembly line: The beverage factory needs to smoothly transport the bottled beverages after filling to the labeling machine, requiring no pollution and low noise. Equipment configuration: Green PVC food-grade belt (3mm thick, FDA certified) horizontal conveyor, length 15 meters, width 400mm, conveying speed 0.5m/s, average daily processing capacity 50,000 bottles.

Replacing the belt of a food grade belt conveyor usually requires the following steps:

Turn off the power of the conveyor and make sure the equipment is in a stopped state.

Remove the original belt and release the connection device of the original belt, making sure to record the installation method and direction of the belt.

Clean the conveyor, clean the belt track and related components of the conveyor, and ensure that there is no residue that interferes with the installation and operation of the new belt.

Install the new belt and place the new belt on the conveyor according to the recorded installation method and direction

Connect the belt and connect the new belt to the transmission device of the conveyor to ensure that the connection is firm and will not loosen or fall off.

As a source manufacturer of conveying equipment, Dahan Machinery has more than ten years of industry experience and technical accumulation. Our food grade belt conveyor uses high-quality belt materials and advanced manufacturing processes to ensure product safety and reliability. Our professional team can customize the design according to customer needs and provide a full range of pre-sales consultation and after-sales services.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!