Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

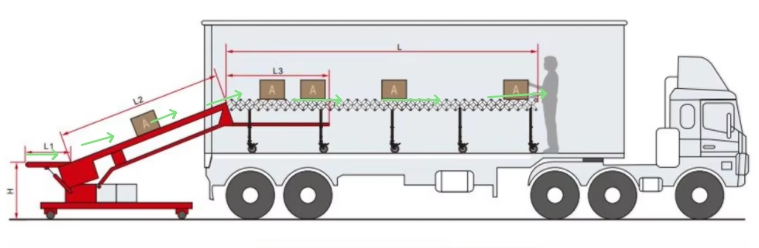

Truck Loading Unloading Belt Conveyor drives the product through the belt, moves along the direction of the conveyor, and finally transports it to the truck and the designated unloading point.

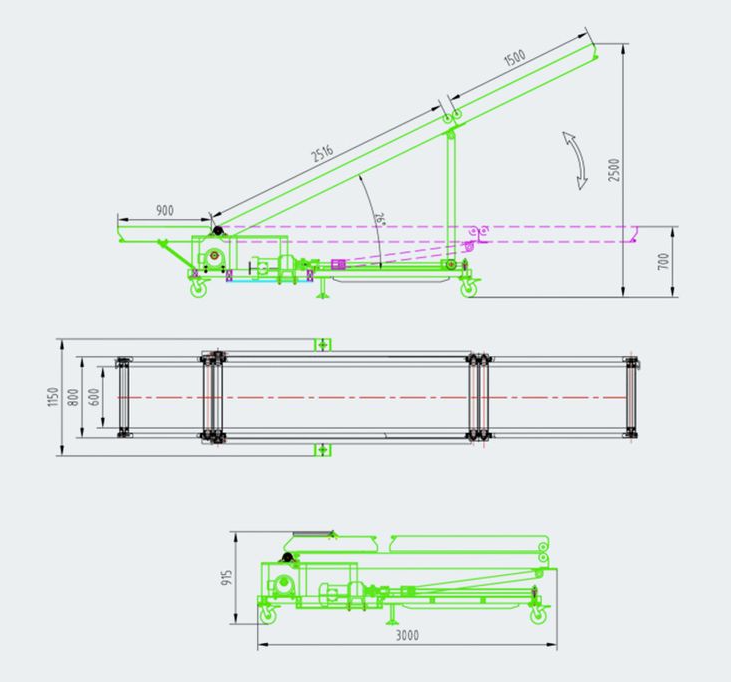

Belt width: 400-1200mm

Fixed length: 3-26 meters

Extension length: 2.8-14 meters (customizable)

Number of conveying sections: two sections, three sections, four sections

Output: 50-400T/H

Power: 8.5KW-18KW (depending on the length)

Application: Commonly used in truck loading and unloading processes in warehouses, cargo distribution centers, and logistics centers.

Promise: Free delivery/5-day delivery/30-day return/customization supported

strong>Truck Loading Unloading Belt Conveyor is designed for fast loading and unloading of bulk materials such as grain, sand, and coal. The belt conveyor adopts a modular and retractable structure, with an adjustable conveying length of 8-20 meters and a hydraulic adjustment of the tilt angle of 0-45° to meet the loading and unloading needs of different models. Equipped with a high-strength anti-slip belt (bandwidth 500-1000mm) and a variable frequency drive system, the conveying capacity can reach 50-300 tons/hour, which is more than 10 times higher than manual efficiency. In addition, we can customize it according to your conveying needs.

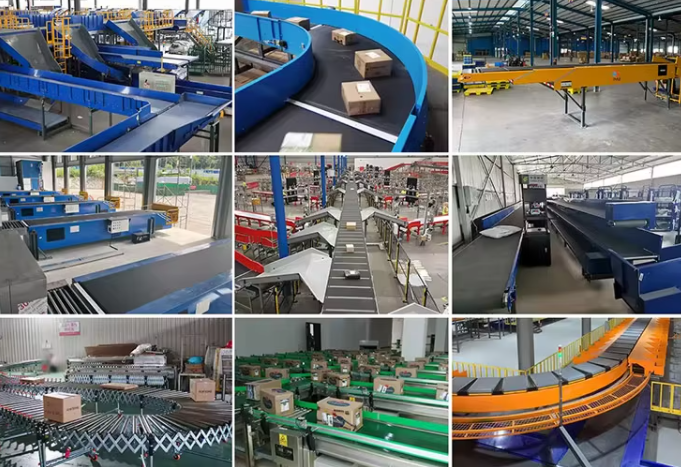

There are many types of truck loading and unloading belt conveyors, including retractable belt conveyors and high-angle belt conveyors:

Retractable belt conveyors: retractable and can adjust the length as needed to adapt to trucks or loading and unloading areas of different lengths.

High-angle belt conveyors: mainly used for inclined conveying of goods, the inclination angle can be adjusted to transport goods from a lower position to a higher position.

Truck loading and unloading belt conveyors have become the core equipment for modern bulk material transportation with their efficient and flexible design. They can easily achieve a loading and unloading efficiency of 50-300 tons/hour. The main advantages are as follows.

Two-stage retractable truck unloading for outbound delivery can be used with other equipment.

The conveyor belt has good popularity, which can ensure that the package maintains a consistent flow operation.

It can be directly transported to the interior of the carriage, reducing the time of manual handling.

It runs smoothly and can reduce the damage of fragile goods.

Truck loading and unloading belt conveyors are widely used in the fields of logistics and freight. The main application fields include but are not limited to the following aspects:

Logistics center: Truck loading and unloading belt conveyors transport the goods on the truck to the designated location, and then transport the goods to be transported to the interior of the carriage through belt conveyors.

Manufacturing plant: Truck loading and unloading belt conveyors load raw materials, semi-finished products or finished products from trucks to production lines or warehouses.

Construction sites: Truck loading and unloading belt conveyors can be used to load waste materials, soil, etc. onto trucks.

Agricultural grain: Truck loading and unloading belt conveyors transport the produced grain to designated granaries.

There are many options for truck loading and unloading belt conveyors to meet different application needs and scenarios.

Conveyor belt type: There are rubber conveyor belts, PVC conveyor belts, and steel cord conveyor belts, which can be selected based on the product's extra characteristics.

Support structure: You can choose the appropriate support structure type according to the unloading height and the needs of loading and unloading operations, such as fixed support, adjustable height support, etc.

Size and capacity: Choose the appropriate size and capacity specifications according to the size, weight and quantity of the loaded and unloaded goods.

Additional functions: Some additional functions, such as dustproof devices, waterproof devices, temperature control devices, etc., can be selected according to your own needs.

| Type | section | Fixed Length (A) | Extension length (B) | Total Length (C) | Belt Length (w) |

| DH-2-6A/4B | 2 | 6000 | 4000 | 10000 | 600/800 |

| DH-3-5AV7B | 3 | 5000 | 7000 | 12000 | 600/800 |

| DH-3-6A/8.6B | 3 | 6000 | 8600 | 14600 | 600/800 |

| DH-4-5A/10B | 4 | 5000 | 10000 | 15000 | 600/800 |

| DH-4-6A/12.6B | 4 | 6000 | 12600 | 18600 | 600/800 |

In general, the inclination angle of the belt conveyor is between 0°~45°.

0°~18°: suitable for conveying coal, ore, etc. with relatively large shapes.

18°~30°: Generally used for conveying grain and cement.

30°~45°: The inclination angle is relatively large and can intelligently convey smaller powder and granular materials.

Truck loading and unloading belt conveyors are usually composed of the following main components:

Belt: It is a component that directly contacts the goods and has different materials to help the goods to be transported normally.

Support structure: used to support and fix the structure of the belt conveyor to ensure its stability and safety.

Unloading port and loading port: used for unloading and loading so that trucks can easily move goods to or from the conveyor.

Drive system: provides the required power and control to ensure that the conveyor can work smoothly as planned.

Guide rollers and rollers: rollers used to guide the running direction of the belt and support the goods.

Safety equipment: including warning signs, protective covers, emergency stop buttons and other safety equipment to ensure the safe operation of truck loading and unloading belt conveyors.

Truck loading and unloading belt conveyors start the conveyor belt to load and transport goods from the parked truck along the running direction of the conveyor, and unload to the designated location or load the goods onto the truck, thereby realizing the loading and unloading of goods.

Truck loading and unloading belt conveyors play an important role in many fields with their high speed and flexibility. The following are customer feedback in different scenarios.

Grain storage and logistics transit: Traditional manual loading has low efficiency (20 tons/hour) and a spillage loss of 3%. Installing a 15-meter retractable belt conveyor (800mm bandwidth) increases the loading speed to 150 tons/hour, and realizes data docking with the grain depot DCS system.

Port bulk cargo collection and distribution: The efficiency bottleneck of ship and truck transshipment is solved by installing multiple 20-meter belt conveyors to form a mobile transfer system. The truck turnover time is shortened from 45 minutes to 15 minutes, and the 24-hour operation capacity reaches 8,000 tons.

Production logistics transfer: Traditional manual handling not only wastes manpower, but also has extremely low efficiency. The telescopic belt conveyor is used, and the height can be adjusted to adapt to different truck heights.

We focus on the research and development and production of truck loading/unloading belt conveyors and have many years of industry experience. The company's product line covers 8-25 meters of retractable belt conveyors, with modular design, a conveying efficiency of 50-500 tons/hour, a lifting system, and an angle adjustment range of 0-30 degrees. We provide customized solutions for grain storage, building materials processing, port logistics and other industries. The company has a complete quality management system, provides 24-hour technical support and lifelong maintenance services to ensure that customers get the best experience.

When choosing a truck loading and unloading belt conveyor, you need to pay attention to the following important matters:

Load capacity: Make sure that the selected truck loading and unloading belt conveyor has sufficient load capacity to withstand the weight and volume of the goods.

Conveyor belt type: Choose the appropriate conveyor belt type according to the nature of the goods being transported and the working environment, such as conveyor belts with characteristics such as wear resistance and high temperature resistance.

Unloading height: Consider the unloading height, select the appropriate support structure and conveyor belt length to ensure the accuracy and efficiency of unloading to the designated location.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!