Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

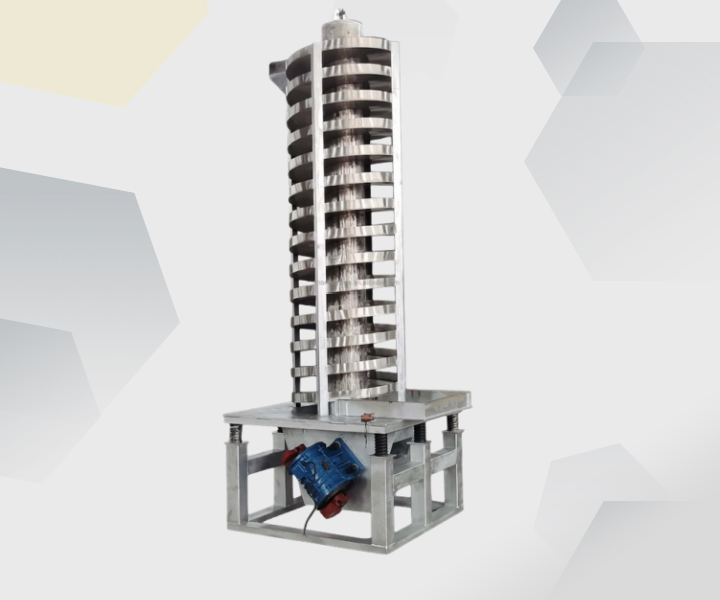

Vibration Cooling Convcyor can convey materials while vibrating.

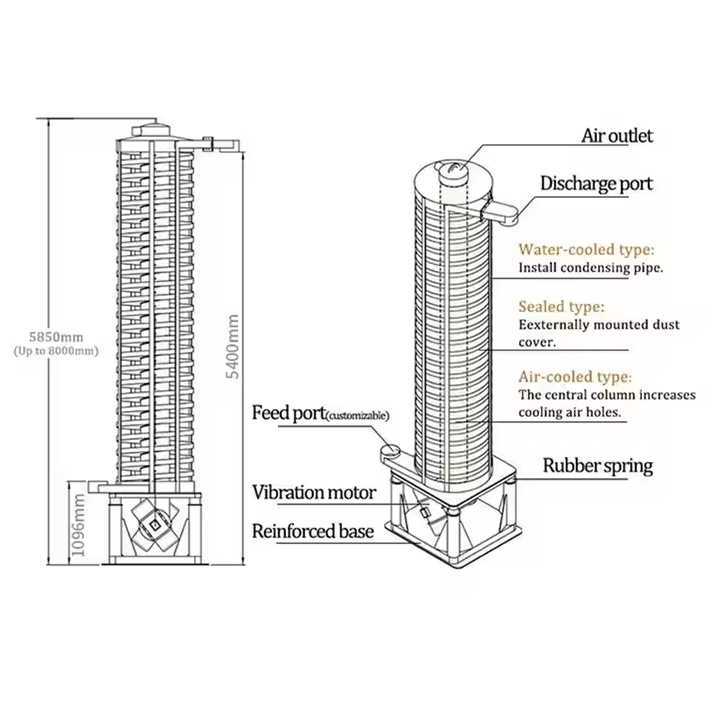

Conveyor trough diameter: 300-900mm Height: ≤6 meters

Conveying capacity: 3.5 tons/hour

Power: 2* (0.4-3)kw

Frame material: SUS304/Carbon Steel

Speed: Adjsutable Speed

Customization: up-vibration, down-vibration, air-cooled, water-cooled, closed, open, 360-degree feeding, etc.

Application: For conveying and lifting powdery, lumpy and short-fiber materials.

Vibration Cooling Convcyor can also be called drying conveyor or cooling conveyor. It uses vibration motor as vibration source, and has cooling, temperature reduction and multi-functional feeding. It combines the advantages of spiral conveying and vibration conveying. It conveys materials from the feed port to the discharge port through spiral blades, and cools the materials by water cooling during the conveying process.

As the source manufacturer of conveying equipment, we sell different types of vibration cooling conveyors for customers to use.

Long-distance vibration elevator: long material conveying stroke, more sufficient heating or cooling of materials

Cold/hot air type elevator: continuous conveying, can cool, dry, and enhance air convection heat dissipation effect by double

Water spray + blowing type elevator: spray water to quickly cool materials to avoid adhesion, and blow air to cool and dry surface moisture

High temperature tolerance: It can convey high temperature materials and can withstand high working temperatures.

Good cooling effect: The materials are cooled by water cooling, and the cooling effect is better.

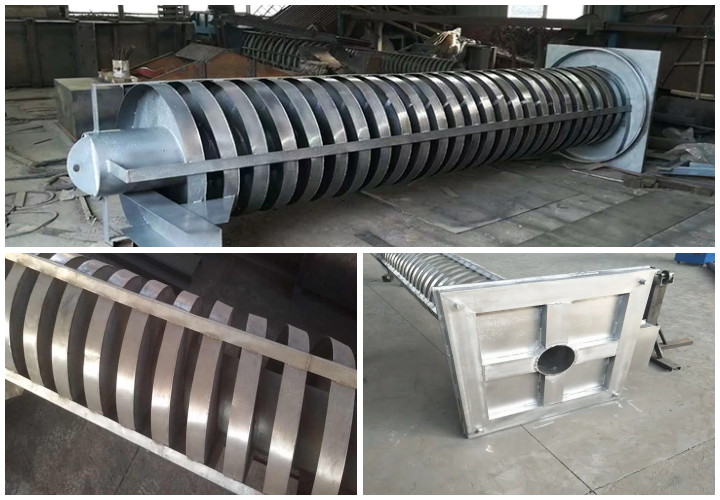

Spiral structure: The structure of the spiral conveyor can ensure that the materials are not blocked and the material conveying is stable.

Customizable: Different specifications and models of vibration cooling conveyors can be customized according to different process requirements.

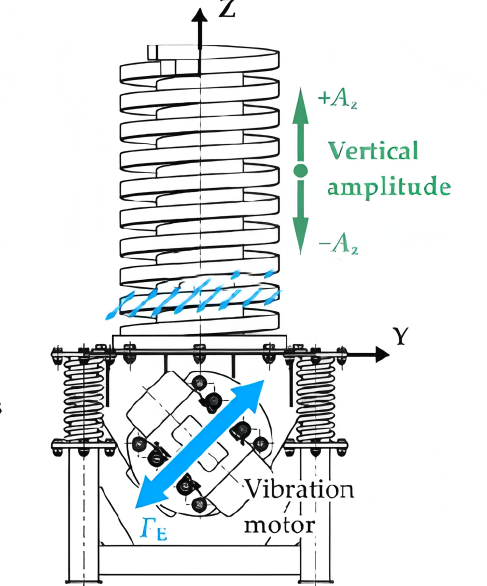

The working principle of the vibration cooling conveyor is based on the combination of spiral conveying and vibration conveying. The high-temperature material enters the conveyor through the feed port, and the spiral blades start to push in combination with the vibration motor, and gradually convey it forward along the conveying pipeline. During the conveying process, the material is cooled by spraying water or water-cooled jackets to reduce the material temperature. The cooled material is discharged from the discharge port to complete the conveying and cooling process.

| Model | Φ | Φ1 | Φ2 | H | H1 | H2 | H3 | D | Lx8 | LdxBd | Φd |

| DZC300 | 300 | 146 | 500 | ~2000 | ~2750 | 40 | 75 | 270 |

680x680 |

\ | 11 |

| DZC500 | 500 | 219 | 850 | ~3000 | ~4020 | 50 | 80 | 475 | 1080x1080 |

880X880 |

13 |

| DZC550 | 550 | 245 | 900 | ~3500 | ~4530 | 55 | 85 | 500 | 1100x1100 |

900X900 |

13 |

| DZC600 | 600 | 273 | 950 | ~4000 | ~5150 | 60 | 85 | 525 | 1100x1100 |

900X900 |

15 |

| DZC800 | 800 | 351 | 1200 | ~4500 | ~5650 | 60 | 90 | 650 |

1300x1300 |

1050X1050 | 15 |

| DZC850 | 850 | 402 | 1250 | ~5000 | ~6150 | 65 | 100 | 675 |

1400x1400 |

11501150 | 17 |

| DZC900 | 900 | 530 | 1300 | ~6000 | ~7180 | 65 | 110 | 700 |

1600x1600 |

13001300 | 17 |

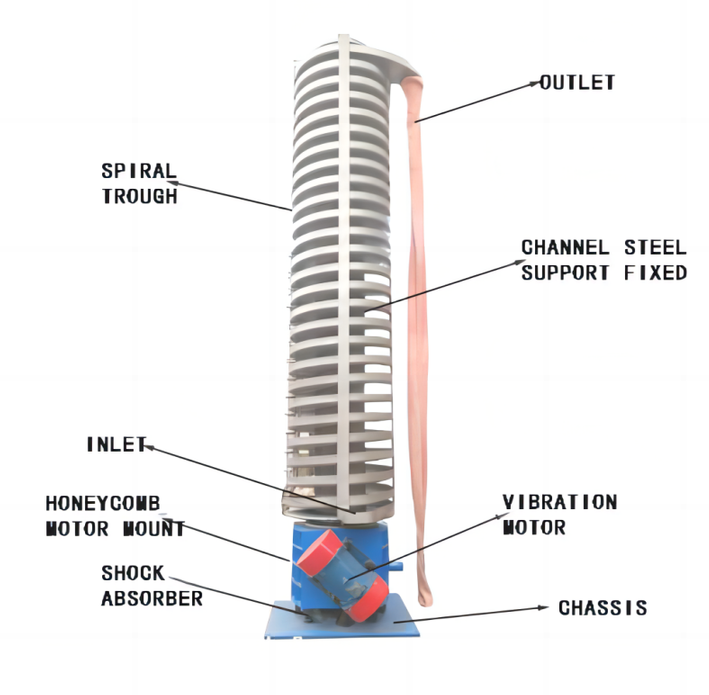

The vibration cooling conveyor is a device that combines vibration conveying with cooling functions. It is mainly used for conveying and cooling granular and powdered materials.

Conveying trough: The main structure used to carry the product, with two forms of closed and 360° loading.

Vibration source installation: The installation position and angle of the vibration source have a very important influence on the vibration effect.

Cooling system: Including cooling medium circulation system, nozzle or heat exchanger, etc., to ensure the cooling temperature of the product is also the most important structure in the equipment.

This type of equipment is widely used in many industries, mainly for processing high-temperature materials and cooling them, including but not limited to the following areas:

Metallurgical industry: used to cool and transport blast furnace charges and metallurgical slag of metallurgical charges.

Thermal power generation industry: convey the burned ash and coal powder to the specified position through the vibration cooling conveyor belt.

Cement industry: used for conveying and cooling cement clinker and cement clinker flue gas treatment.

Chemical industry: petroleum coke and naphtha in the chemical industry can also be cooled and transported by vibration cooling conveyors.

Generally speaking, the price range of vibration cooling conveyors is large, ranging from tens of thousands to hundreds of thousands of yuan. The main factors affecting its price are as follows.

Equipment size: Different conveying volumes, conveying distances, and different materials and drive methods will affect the price.

Configuration and function: If you need to install some control systems and alarm systems, these configurations will also increase the overall price.

Degree of customization: If your site and conveying requirements require some customized services, the price will also increase accordingly.

We are a manufacturer focusing on the production of conveying equipment. In the field of vibrating cooling conveyors, we have rich production experience and a professional technical team. We continue to invest in research and development resources to continuously optimize the working principles of our vibrating cooling conveyors. Combining the interaction principles of heat transfer, mass transfer and transmission, we ensure the efficient operation of the equipment. We also have special solutions for the vibration problems of cooling conveyors.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!