Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

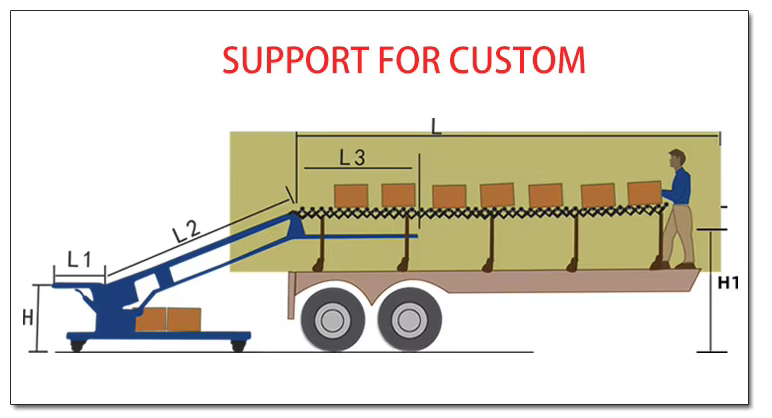

Belt width: 400-1200mm

Fixed length: 3-26 meters

Extended length: 2.8-14 meters (can be customized)

Number of conveyor sections: two-section, three-section, four-section

Capacity: 50-400T/H

Power: 8.5KW-18KW (depending on the length)

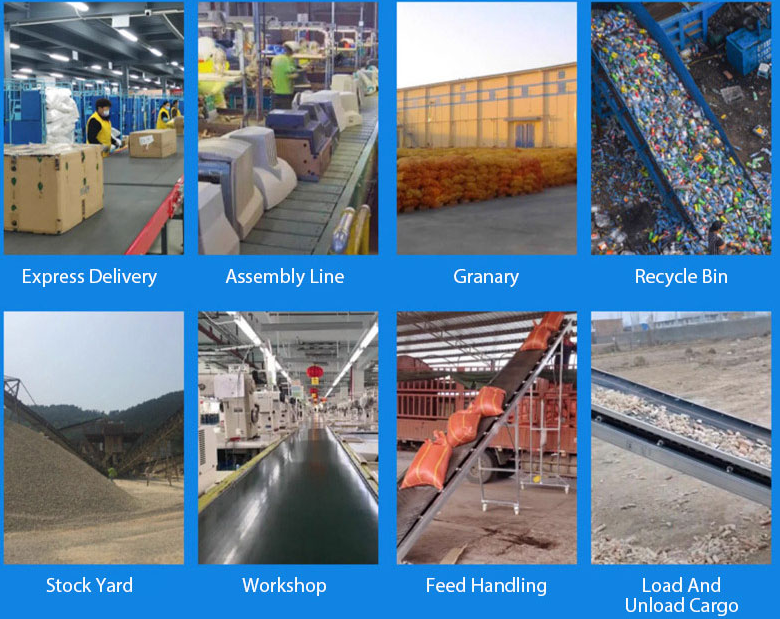

Application: Typically used in warehouses, distribution centers and shipping facilities for loading and unloading trucks and containers. They are also used in manufacturing plants and assembly lines to transport materials to different workstations.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Truck Loading Conveyor is the core equipment of modern logistics loading and unloading system, mainly used for fast loading of bulk materials, boxed goods and bagged materials. It realizes seamless connection from warehouse to transport vehicle through retractable and adjustable conveying mechanism, and is widely used in grain, building materials, chemical industry, express delivery and other industries.

Truck Loading Conveyors are constructed of high-strength carbon steel or stainless steel, offering excellent wear and corrosion resistance. They are suitable for loading a variety of bulk materials, including grain, coal, and ore. A wide range of product types are available, including fixed, mobile, and telescopic configurations to meet diverse site requirements. They offer comprehensive customization options, including adjustable conveying lengths, angles, and drive modes. Additional features such as dust covers and weighing systems are also available.

Truck loading conveyors are primarily categorized as adjustable, portable, and telescopic. Adjustable conveyors offer adjustable angles and are suitable for fixed loading and unloading points; portable conveyors are easily relocated with wheels and are suitable for temporary operations; and telescopic conveyors offer variable lengths and support high-speed loading.

Adjustable conveyors: offer an adjustable conveying angle from 0° to 45°, accommodating trucks or containers of varying heights. These conveyors are typically fixed installations and are suitable for fixed loading and unloading points such as warehouses and docks, meeting the frequent angle adjustments required by various industries.

Portable conveyors: feature rollers for flexible movement to various loading and unloading points. Their lightweight structure allows for manual transfer or forklift operation, making them suitable for temporary loading and unloading operations on construction sites and farms.

Telescopic conveyors :offer an adjustable conveying length between 6 and 20 meters, enabling them to cover varying distances. They support automated operation to reduce manual adjustments and are suitable for loading containers and trucks.

It has three core advantages: high speed and energy saving, flexible adaptation, and easy operation. Its modular structure supports adjustable angles, mobile transitions, or free extension and retraction, and one person can complete precise loading and unloading.

Shortened vehicle loading and unloading time: Compared with pure manual handling, conveyors can continuously and stably transport goods, greatly shortening vehicle loading and unloading time and improving turnover rate.

Reduced labor intensity: Reduced the number of times workers need to bend over and carry heavy objects repeatedly, reducing physical exertion and fatigue.

Reduced cargo damage: The automated conveying process is smoother, reducing cargo collisions and damage caused by improper manual operation.

Flexibility and adaptability: Many types of truck loading conveyors (especially telescopic ones) can adjust the length and height to accommodate trucks of different sizes and cargo stacking requirements.

|

Type |

section |

Fixed Length (A) |

Extension length (B) |

Total Length (C) |

Belt Length (W) |

|

DH-2-6A/4B |

2 |

6000 |

4000 |

10000 |

600/800 |

|

DH-3-5A/7B |

3 |

5000 |

7000 |

12000 |

600/800 |

|

DH-3-6A/8.6B |

3 |

6000 |

8600 |

14600 |

600/800 |

|

DH-4-5A/10B |

4 |

5000 |

10000 |

15000 |

600/800 |

|

DH-4-6A/12.6B |

4 |

6000 |

12600 |

18600 |

600/800 |

Truck loading conveyors use electric motors as power sources. Through transmission devices such as gear boxes, belts or chains, power is transmitted to the drive rollers of the conveyor belt, causing it to rotate and drive the conveyor belt, laying the power foundation for cargo transportation. The goods are placed at the feed end and move along the belt surface by the friction generated by the roughness of the conveyor belt surface. Its frame can flexibly adjust the height and tilt angle through hydraulic or mechanical devices, accurately docking with different truck compartments to ensure smooth loading of goods.

It is suitable for various fields such as grain, coal, building materials, and chemicals. Its flexible adjustable angle, portable or telescopic extension function can easily adapt to different loading scenarios such as trucks and containers.

Logistics warehouse: In logistics warehouses, truck loading conveyors are used to quickly and accurately load stored goods onto transport trucks. Whether it is a small express parcel or a large pallet cargo, it can be loaded by a conveyor.

Production plant: In a production plant, a truck loading conveyor can connect the production line and the truck to achieve a seamless connection from production to transportation of products.

Port terminal: Port terminals need to load a large amount of goods onto trucks for transshipment. Truck loading conveyors can be used in conjunction with the port's loading and unloading equipment to quickly load the goods unloaded from the ship onto trucks.

Agricultural product processing enterprises: Agricultural product processing enterprises need to load a large amount of agricultural products onto trucks during the harvest season and transport them to processing plants or markets.

Building materials market: Various types of building materials in the building materials market, such as cement, sand, bricks, etc., usually need to be loaded onto trucks and transported to construction sites. Truck loading conveyors can easily handle these heavy and large-volume goods.

Large e-commerce logistics center: tens of thousands of orders per day, with a wide variety of goods, ranging from electronic products to daily necessities, mostly packaged in cartons. In the past, manual loading of trucks was inefficient, often leading to backlogs and delayed shipments. The situation has changed significantly after the introduction of telescopic truck loading conveyors. The conveyor can flexibly adjust the length and height to accurately dock different types of trucks.

Food processing company: A food processing company that mainly produces bagged snacks and bottled beverages needs to frequently load products onto trucks and transport them to distributors in various places. Previously, forklifts were used in conjunction with manual handling, which was not only inefficient but also prone to wear and tear on product packaging. The company used a truck loading conveyor with a buffer device and an anti-skid conveyor belt. In order to solve the problem of easy slippage of bagged snacks, the conveyor belt is designed with a special texture to increase friction; for bottled beverages, the buffer device can reduce the vibration impact during loading.

Building materials production factory: The main products include bricks, bagged cement, and building sand. Bricks are large and heavy, cement is easy to generate dust, and construction sand is highly fluid. In the past, loading was difficult and harmful to workers' health. To solve these problems, the factory customized different types of truck loading conveyors. For bricks, a high-strength, large-load flat-plate conveyor is used. Its sturdy frame and wear-resistant conveyor belt can easily handle the handling of bricks.

Different material properties (such as particle size, fluidity, humidity, corrosiveness, etc.) directly affect the selection of conveyors. The following are selection recommendations.

Granular bulk materials: grain, feed, coal, etc., good fluidity, not easy to adhere, and allow slight impact. Telescopic belt conveyors and inclined belt conveyors are recommended. The belt speed should not be too fast (1~2.5m/s) to prevent crushing. Add sidewalls or anti-slip strips to prevent materials from sliding.

Powdered materials: cement, fertilizers, flour, easy to generate dust and absorb moisture, fully enclosed screw conveyors are recommended.

High viscosity/easy to stick materials: feed, molasses, sludge, easy to stick to belts/spiral blades, poor fluidity, scraper conveyors and shaftless screw conveyors are recommended, and the contact surface is Teflon coated or stainless steel polished.

Heavy/sharp materials: ore, gravel, metal scraps, high wear and high impact, heavy chain conveyors and corrugated sidewall belt conveyors are recommended.

The Multifunctional Truck Loading Conveyor Combination Solution leverages the core strengths of different conveyor types, combining them with scenario-specific design requirements to create an integrated operating system. This system effectively addresses diverse challenges, including multi-product cargo, complex sites, and dynamic loading and unloading.

Fixed Loading and Unloading Points: The system utilizes an adjustable conveyor as the backbone, connected in series with a short telescopic section. The adjustable section adjusts from 0° to 45° to accommodate the height of the truck or container, while the telescopic section precisely controls the drop point. Equipped with a non-slip belt coating, the system can handle both bulk materials like grain and packaged goods like cartons.

Temporary Dynamic Sites: The system utilizes a portable conveyor as the mobile carrier, equipped with adjustable angle attachments and elevating outriggers. The wheeled design allows for cross-site transfers, with an extended angle adjustment range of 0° to 60°. The outriggers accommodate uneven surfaces, enabling the transfer of bagged cement, agricultural products, and other items from the ground to the truck.

Long-Distance Precision Loading: The system utilizes a telescopic conveyor as the backbone, integrated with an adjustable end-steering mechanism and an intelligent positioning system. The 6-20 meter telescopic length covers different carriage depths. The terminal steering mechanism can rotate 360° to adjust the direction of material drop. Combined with sensors to detect the height of cargo stacking in real time, it automatically starts and stops or adjusts the conveying speed. It is suitable for express delivery and large-scale cement handling scenarios.

We have been focusing on the research and development and manufacturing of truck loading conveyors for many years, and can accurately grasp the characteristics of various materials and customize suitable conveyors. Whether it is dealing with block, granular, powdery or packaged materials, the equipment produced is durable and energy-efficient. From design, production to installation and after-sales, we provide one-stop service. With reliable quality and considerate service, our products are sold all over the country, and have won high praise from customers in multiple industries such as logistics, building materials, and food, and fully help companies improve loading efficiency.

We offer high-speed, durable, and intelligent loading solutions! Our versatile, adjustable, mobile, and telescopic designs meet all your bulk material handling needs. We offer fully customized services, from dust covers to intelligent weighing systems.

High efficiency and energy saving: 5~10 times higher than traditional manual loading efficiency, reducing operating costs.

Intelligent control: Optional PLC automation system to achieve automatic metering, anti-eccentric loading, and remote monitoring.

Sturdy and durable: Key components are made of wear-resistant steel plates and imported bearings, with a service life of more than 10 years.

Customized service: Design length, angle, material, and drive mode according to customer needs.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!