Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Telescopic Belt Conveyor has become the core equipment for modern bulk and piece goods transportation with its freely adjustable length body design. Its core advantage lies in its dynamic telescopic ability, which can be flexibly extended or contracted within a range of 10-50 meters according to the operation requirements. It is perfectly adapted to port loading and unloading, coal mining, warehousing and logistics, etc., significantly reducing equipment displacement or transfer links, and improving operation efficiency by more than 30%. The modular body structure takes into account both compactness and maintenance convenience, and cooperates with the automatic control system to achieve energy saving and unmanned operation.

The Telescopic Belt Conveyor offers both fixed and mobile options, supporting customization in lengths from 6 to 30 meters and inclinations from 0° to 45°. Available in carbon steel or stainless steel materials and with electric, hydraulic, or diesel drive options, it also features expanded dust protection and weighing capabilities, increasing loading and unloading efficiency by 80% in logistics center applications.

We offer different types of mobile telescopic belt conveyors. We can recommend a customized conveying solution based on your production needs and can also modify the equipment to suit your materials. The main types are as follows.

Mobile telescopic belt conveyors: Equipped with tires or tracks, they offer flexible mobility and are suitable for construction sites, temporary storage yards, agricultural grain loading and unloading, and require no fixed installation, allowing for quick relocation.

Fixed telescopic belt conveyors: Fixedly installed in factories, docks, or production lines, they are suitable for mines, logistics centers, and factory assembly lines. They offer a stable structure, are suitable for conveying materials over distances of 20-30 meters, and have low maintenance costs and a long service life.

Hydraulic telescopic belt conveyors: Using a hydraulic system to control extension and lifting, they offer powerful power, high load capacity, and easy adjustment, making them suitable for loading and unloading heavy materials such as ore and coal.

Fully automatic telescopic belt conveyors: Integrated with a PLC control system, they automatically adjust length and angle. They are suitable for smart warehousing and automated logistics, enabling unmanned operation and saving labor.

The core intelligence of the telescopic belt conveyor is reflected in the three-level operation mode supported by the PLC control system, which meets the automation needs of different scenarios through differentiated logic design.

Manual mode: "Inching" operation is realized through the body button box or remote control panel, and the start and stop of the conveyor belt and the movement of the telescopic frame can be controlled separately. This mode does not require complex programming and is suitable for non-continuous operation scenarios such as temporary loading and unloading at ports and emergency transfer in warehouses.

Semi-automatic mode: The system can store 2-3 groups of commonly used working lengths (such as 5 meters / 8 meters / 12 meters). The operator selects the corresponding mode through the touch screen or buttons, and the PLC automatically completes the positioning of the telescopic frame and the belt tensioning adjustment.

Fully automatic mode: By integrating sensors such as material level meters, photoelectric switches, and encoders, the system can sense the material position and conveying status in real time and automatically adjust the parameters.

The telescopic belt conveyor has shown significant advantages in multiple application scenarios due to its unique telescopic design, especially in terms of flexibility, efficiency and space adaptability.

Dynamically adjust the length: Through the telescopic mechanism, the body length can be freely extended or contracted according to work requirements, without the need to frequently disassemble and assemble the equipment, and quickly adapt to the 5-30 meter transportation needs.

Adapt to changing working conditions: Suitable for scenarios where the location of loading and unloading points changes frequently (such as port loading and unloading, coal mine excavation working face), reducing the need to move equipment or add transfer conveyors.

Seamless operation: Compared with fixed conveyors, the telescopic body can realize continuous material transportation, avoid interruption of the process due to distance changes, and improve production efficiency.

Compact structure design: It takes up little space when in the retracted state, suitable for sites with limited space.

The telescopic belt conveyor adopts the four-dimensional core architecture of "drive system + telescopic frame + conveyor belt + control system". During operation, the material falls into the conveyor belt from the fixed end feed port, and the motor drives the roller to operate to achieve conveying. When the length needs to be adjusted, the control system sends a command, and the drive device pushes the telescopic section to move forward and backward along the track. At the same time, the tensioning system automatically adjusts the belt tension to ensure smooth conveying.

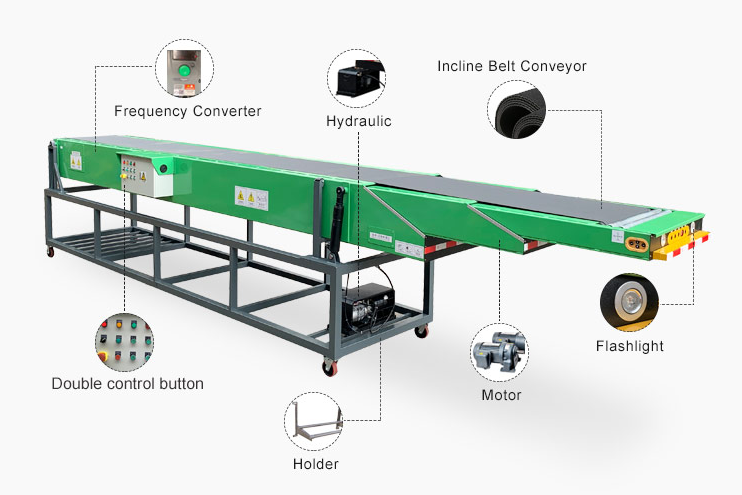

A telescopic belt conveyor's main structure includes the conveyor belt, drive unit, telescopic mechanism, tensioning device, and control system. The conveyor belt transports the material, the drive unit provides power, and the telescopic mechanism adjusts the length, all working together to ensure flexible and fast conveying.

Main conveying section: This is the fixed base part of the conveyor, which usually contains the drive motor, control system and main frame.

Telescopic section: One or more sections of the movable body that can slide within the main conveying section. Driven by a chain, gear or synchronous belt drive system, these telescopic sections can be smoothly extended forward or retracted backward under the drive of the motor.

Conveyor belt system: A complete conveyor belt runs through all telescopic sections and the main conveying section. The specially designed belt storage and tensioning system ensures that no matter what length the conveyor is at.

Control system: The operator can easily control the telescopic movement of the conveyor, the forward and reverse rotation of the belt and the speed through the control panel located at the front or rear end of the conveyor.

Support and mobile structure: The conveyor is usually installed on a sturdy base and can be fixed or equipped with heavy-duty casters to enable it to be flexibly moved between different loading and unloading platforms.

Telescopic belt conveyors are suitable for a wide range of product types and can transport piece goods such as cartons and parcels, bulk materials such as grains and ores, as well as large items such as home appliances and building materials.

Granular/powdered: wheat, corn, cement, coal powder, fertilizer, use anti-skid conveyor belt to prevent slipping, optional sealing cover to reduce dust flying; powder materials need to control the conveying angle ≤18° to avoid accumulation.

Block/granular: ore, iron ore, quartz sand, coal, gravel, equipped with wear-resistant rubber belt and anti-tear layer, hopper feed port equipped with grille to screen oversized bulk materials, conveying speed controlled at 0.8-1.2m/s to prevent impact.

Bag/box finished products: fertilizer bags, express parcels, food boxes, use flat conveyor belt + side baffle design, conveying angle ≤15°; with photoelectric sensor to automatically detect material position to avoid stacking and extrusion.

Mildly sticky materials: wet sand, clay, dough, sauce, use PVC or PU material conveyor belt with adhesion resistance, with high-frequency vibration device to prevent material adhesion; add scraper cleaner at the rear of the conveying.

The telescopic belt conveyor can freely adjust the length, reduce equipment displacement and transfer, and is especially suitable for scenes with frequent changes in loading and unloading points; while the fixed conveyor needs to be stopped for adjustment, occupies a large space, and is only suitable for fixed distance transportation.

|

Scenario |

Advantages of Retractable Type |

Limitations of Fixed Type |

|

Frequent changes in loading/unloading points |

Dynamic adjustment without disassembly |

Requires shutdown for relocation or additional equipment |

|

Long-distance segmented conveying |

Single unit covers full distance, reduces transfers |

Multiple units in series increase failure points |

|

Narrow/irregular spaces |

Saves space in retracted state |

Fixed length may not fit installation requirements |

Telescopic belt conveyor solutions are customized for different scenarios and include hydraulic, fully automatic, mobile, and explosion-proof models. They are suitable for ports, warehousing, construction, chemical, and other fields, improving efficiency and meeting specialized needs.

Port Coal Loading and Unloading: The customer required fast coal loading and unloading and adaptability to different vehicle types. The solution was a 20-meter-long, 1000mm-wide hydraulic telescopic belt conveyor equipped with a dust cover and an automatic weighing system. This ultimately increased loading and unloading efficiency by 80%.

Grain Storage and Logistics Center: A PLC-controlled, 15-meter-long, fully automatic telescopic belt conveyor with integrated flow sensors for precise material discharge control was implemented. This enabled unmanned loading and reduced labor costs by 70%.

Construction Sand and Gravel Transfer Project: Flexible mobile transport of sand and gravel was required at a temporary site. The solution was a 12-meter-long mobile telescopic belt conveyor with a tire base, equipped with a wear-resistant rubber belt and anti-slip design. This equipment requires no fixed installation and can be operational in 30 minutes.

A powder packaging line in a chemical plant requires conveying powders in an explosion-proof environment. The solution is a 10-meter-long, explosion-proof telescopic belt conveyor with a fully enclosed structure and an electrostatic eliminator. This equipment ensures the safe transportation of flammable powders such as sulfur and starch.

Dahan Machinery is a professional telescopic belt conveyor R&D and manufacturer. We have advanced production equipment and a complete testing system. Our products are widely used in coal mines, ports, electricity, building materials, logistics and warehousing industries. The fuselage length can be flexibly adjusted (10-50 meters), equipped with an intelligent control system to achieve automatic operation and remote monitoring. It provides customized conveying solutions for many domestic and foreign companies and has won wide acclaim. We insist on technological innovation and are committed to providing customers with more reliable and intelligent conveying equipment to help the industry develop efficiently.

The conveying distance of a telescopic belt conveyor is flexibly adjustable, typically ranging from 6 to 30 meters. Mobile types are generally suitable for short-distance conveying of 6-15 meters, while fixed types can cover long distances of 20-30 meters. Some customized equipment, with its multi-stage telescopic design, can extend to over 50 meters. This meets the needs of both short-distance transport in small sites and long-distance transport in large industrial environments such as ports and large warehouses.

Telescopic belt conveyors come in a variety of styles, including single-stage telescopic belt conveyors, which feature a simple structure and adjust their length by telescoping a single section. They are suitable for fixed or temporary conveying in small and medium-sized sites. Multi-stage telescopic belt conveyors utilize a multi-stage nested design, significantly extending conveying distances and making them suitable for long-distance applications such as large warehouses and ports. Hydraulic-arm telescopic belt conveyors utilize a hydraulic system to drive the boom's extension and extension, offering precise adjustment and a strong load capacity. They are commonly used for loading and unloading heavy materials. Mobile telescopic belt conveyors feature wheels on the bottom for flexible movement, facilitating transfers between different work locations.

With its flexible and variable conveying length and efficient and stable material transmission capabilities, the telescopic belt conveyor has become the core equipment for modern industrial flexible conveying. It can dynamically adjust according to changes in loading and unloading points, site space, etc., adapt to multiple types of materials, effectively overcome the limitations of fixed conveyors, and is widely used in logistics, mining and other fields.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!