Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

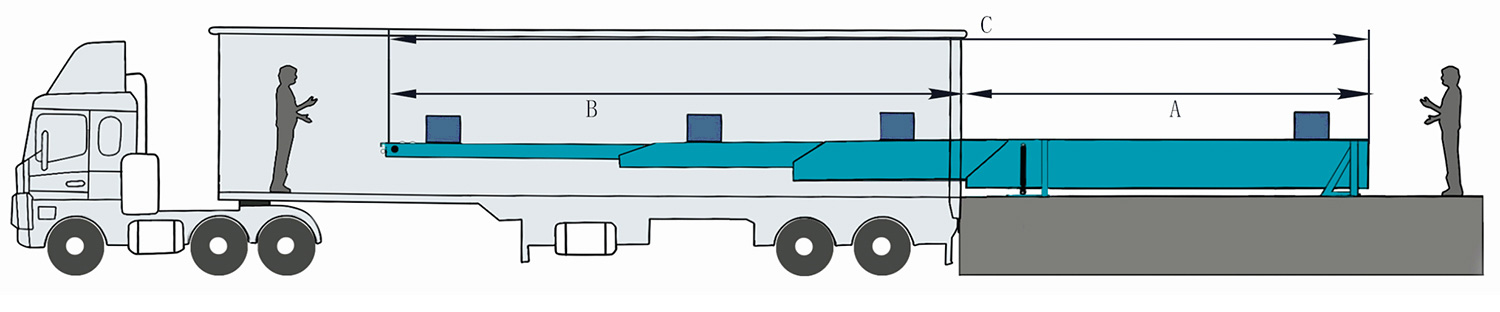

Telescopic Belt Conveyor for truck loading unloading is a telescopic belt conveyor specially designed for truck loading and unloading scenarios, which reshapes logistics efficiency with intelligent telescopic and flexible docking. Through hydraulic drive and modular design, it can be quickly extended to the interior of the car, accurately matching the height and length of different models without frequent manual adjustments. The high-strength wear-resistant belt is matched with a stable transmission system to achieve high-speed and smooth transportation of multiple types of materials such as bulk goods and boxed goods, with an hourly throughput of up to 100 tons.

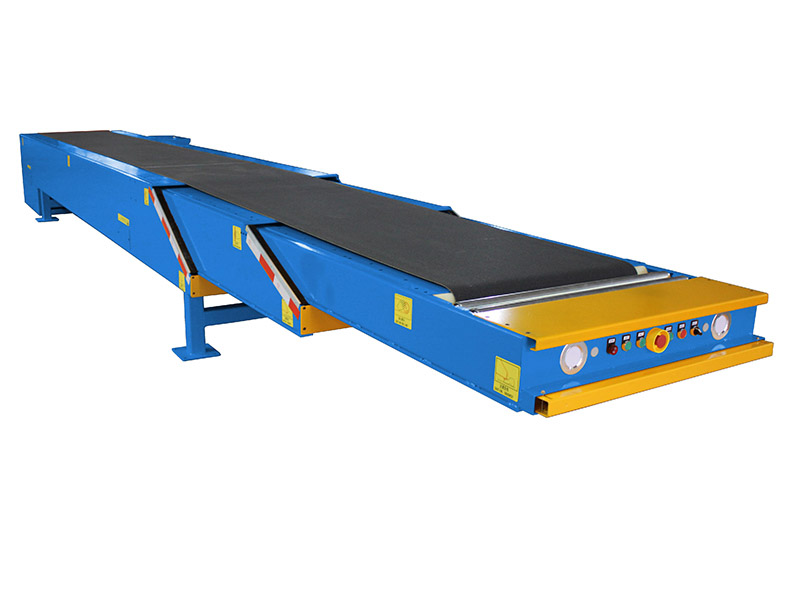

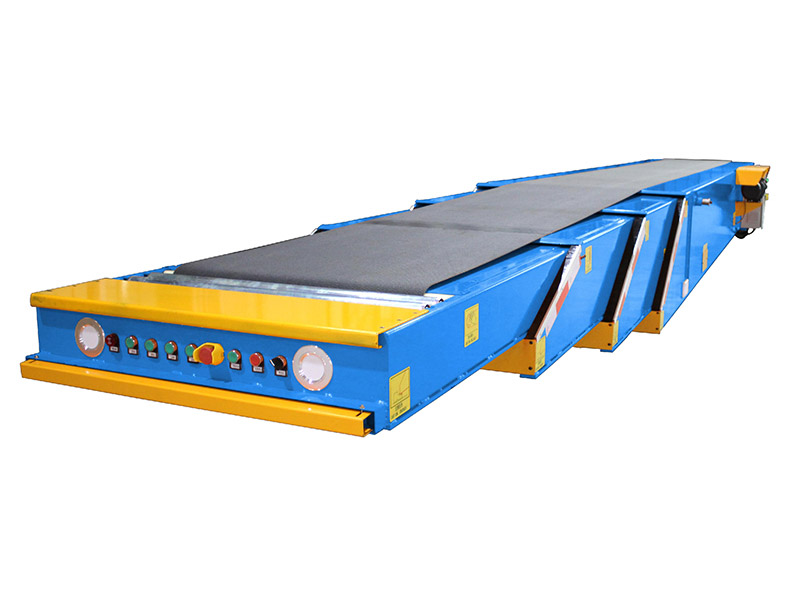

The three-section telescopic belt conveyor can be adjusted in three lengths, flexibly adapting to different scenarios. Its compact structure provides wide coverage when extended, and space-saving when retracted, making it easy to move and store.

| Mocel | Capacity | RetractedLength L1 | ExtensionLength L2 | TotalExtendedLength L3 | ThicknesofConveyorH1 | MininurElevationH2 | MaximumElevationH3 | BeltWidthC1/C2 | TotalWidth |

| TBC3-3/4 | 80kg | 3000 | 4000 | 7000 | 550 | 580 | 1050 | 600/800 | C+345 |

| TBC3-4/5.4 | 80kg | 4000 | 5400 | 9400 | 550 | 580 | 1100 | 600/800 | C+345 |

| TBC3-5/7 | 80kg | 5000 | 7000 | 12000 | 550 | 580 | 1200 | 600/800 | C+345 |

| TBC3-6/8.4 | 80kg | 6000 | 8400 | 14400 | 550 | 580 | 1300 | 600/800 | C+345 |

The four-section telescopic belt conveyor can be adjusted in four lengths, offering flexible length adjustment. It is suitable for various loading and unloading scenarios and can precisely connect to different vehicle types, facilitating cargo transfers in logistics, warehousing, and other industries.

| Mocel | Capacity | RetractedLength L1 | ExtensionLength L2 | TotalExtendedLength L3 | ThicknesofConveyorH1 | MininurElevationH2 | MaximumElevationH3 | BeltWidthC1/C2 | TotalWidth |

| TBC4-5/10 | 80kg | 5000 | 4000 | 10000 | 580 | 220 | 1700 | 600/800 | C+390 |

| TBC4-6/12.3 | 80kg | 6000 | 5400 | 12300 | 580 | 220 | 1800 | 600/800 | C+390 |

| TBC4-6/12.3 | 80kg | 7000 | 7000 | 15000 | 580 | 220 | 1950 | 600/800 | C+390 |

| TBC4-7.5/16 | 80kg | 7500 | 8400 | 16000 | 580 | 220 | 2050 | 600/800 | C+390 |

The five-section telescopic belt conveyor offers flexible extension and retraction, achieving substantial length when extended and easy storage when retracted. It is suitable for various scenarios, can be adjusted in height and angle, and can be used for long-distance conveying.

| Mocel | Capacity | RetractedLength L1 | ExtensionLength L2 | TotalExtendedLength L3 | ThicknesofConveyorH1 | MininurElevationH2 | MaximumElevationH3 | BeltWidthC1/C2 | TotalWidth |

| TBC5-6/16 | 80kg | 6000 | 16000 | 22000 | 670 | 200 | 2020 | 600/800 | C+440 |

| TBC5-7.5/21 | 80kg | 7000 | 21000 | 28500 | 700 | 200 | 2300 | 600/800 | C+450 |

This telescopic belt conveyor for truck loading and unloading utilizes a hydraulic/electric system for intelligent positioning, flexible extension and retraction, and angle adjustment. During operation, the conveyor belt precisely unloads materials into the truck bed at an adjustable speed. A real-time monitoring system ensures operational stability, and the conveyor automatically retracts after operation. This significantly improves loading and unloading efficiency and reduces labor costs, making it a core piece of equipment for modern logistics loading and unloading.

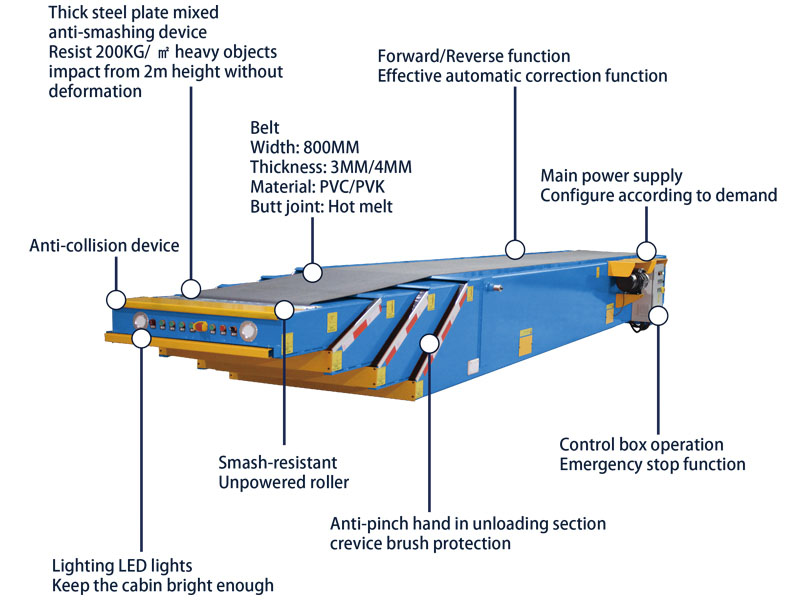

The telescopic belt conveyor is mainly composed of a conveyor belt, a bracket, a telescopic mechanism and a drive system. Its working principle is to drive the conveyor belt to move through an electric motor to transport the goods from the inside of the truck to the ground or in reverse. The telescopic mechanism allows the conveyor to be adjusted according to the height and loading and unloading requirements of the truck to ensure efficient and safe transfer of goods.

A telescopic belt conveyor for truck loading and unloading primarily consists of a conveyor belt, drive unit, telescopic mechanism, frame, tensioning device, and electrical control system. These components work together to achieve flexible, retractable loading and unloading.

Conveyor belt: Common types include rubber, PVC, and PU belts. It is the core load-bearing component of the conveyor, directly contacting the material and transporting it from one location to another. Driven by friction with the drive roller, it rotates under the motor's power, achieving continuous material conveyance.

Drive unit: A three-phase asynchronous motor is typically used, with the appropriate power selected based on the conveyor's conveying capacity, length, and other parameters. The motor provides power to the conveyor and drives the conveyor belt.

Reducer: Converts the motor's high speed and low torque into low speed and high torque to meet the conveyor belt's drive requirements. Common reducer types include gear reducers and worm gear reducers.

Electric actuator: Consists of a drive motor, reduction gear, screw, nut, guide bushing, actuator, slide, spring, housing, turbine, and micro-control switch. The motor drives the screw to rotate, causing the nut to drive the push rod in linear motion, thus extending and retracting the telescopic section of the conveyor.

Main frame: Typically constructed of welded or bolted steel, it possesses sufficient strength and rigidity to support the weight of the conveyor belt, drive unit, and material.

Support feet: Available in fixed and adjustable configurations. Fixed support feet secure the conveyor to a flat, solid surface; adjustable support feet utilize adjustment bolts or hydraulic mechanisms to adjust the height and level of the conveyor based on the surface's flatness and loading and unloading height requirements.

Control box: Houses various electrical components, such as circuit breakers, contactors, relays, and PLCs. Circuit breakers provide overload and short-circuit protection; contactors and relays control the motor's start, stop, and forward/reverse rotation.

Operation panel: Equipped with buttons, indicator lights, and a display, the operator can control the conveyor's start, stop, and retraction/extension functions using buttons.

The telescopic belt conveyor has become a revolutionary equipment in the field of truck loading and unloading with its adjustable length and intelligent hydraulic lifting function. Its characteristics are as follows.

Telescopic design: The conveyor can be extended and retracted as needed to adapt to trucks of different heights and reduce loading and unloading time.

Rapid deployment: modular design, one person can complete assembly in 10 minutes, suitable for all types of trucks and sites

Intelligent control: integrated weighing measurement (±0.5% accuracy) and automatic deviation correction to ensure accurate loading and unloading

Durable and reliable: key components use imported bearings and wear-resistant steel plates with a lifespan of more than 50,000 hours

Multi-scenario application: optional explosion-proof, dust-proof or cold-resistant configuration to meet harsh environments such as grain, building materials, ports, etc.

The application scenarios of telescopic belt conveyors are very wide, mainly including.

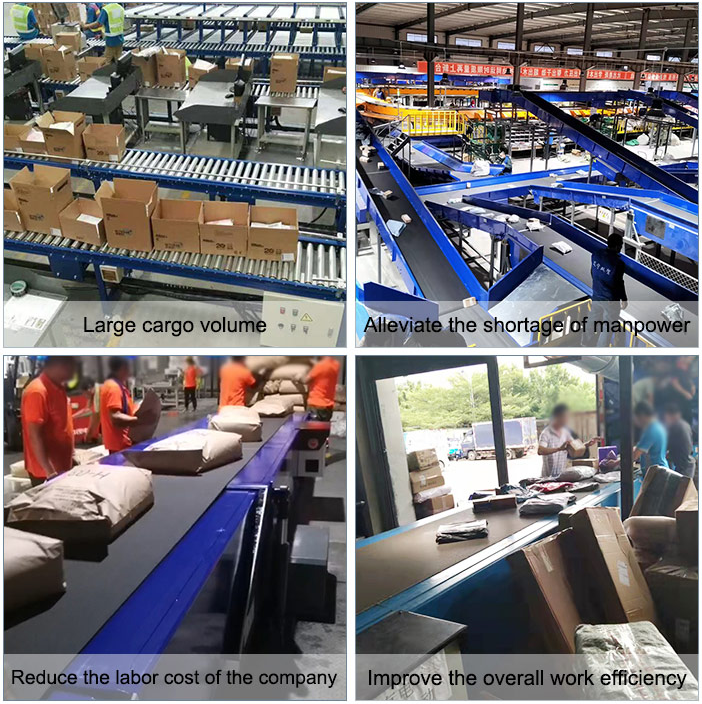

Logistics center: In large logistics centers and distribution centers, it is used to quickly load and unload goods and improve overall operational efficiency.

Warehousing management: In the storage and management of goods, it helps to quickly transfer goods and reduce storage and retrieval time.

Manufacturing: Cargo transfer between production lines and warehouses to ensure smooth production processes.

Ports and docks: Used for cargo loading and unloading between ships and ground transportation vehicles to improve port operation efficiency.

To choose a telescopic belt conveyor suitable for your truck loading and unloading, you need to consider the following key aspects.

Conveying capacity: Determined according to the amount of goods loaded and unloaded by trucks on a daily basis. For example, large logistics warehouses load and unload a huge amount of goods every day, so it is necessary to choose a conveyor with strong conveying capacity and can transport more goods per unit time.

Telescopic length and height: It should be selected based on the height of the truck compartment and the distance between the loading and unloading platform and the truck in the actual operating environment.

Cargo characteristics: Different goods have different requirements for conveyors. If it is bulk materials, such as coal, grain, etc., it is necessary to consider the belt width, inclination and anti-leakage design of the conveyor; if it is boxed goods, it is necessary to pay attention to the friction and carrying capacity of the belt to ensure that the goods do not slip or get damaged during transportation.

Working environment: The size of the workplace will limit the size and layout of the conveyor. For example, in a warehouse with narrow space, it is necessary to choose a compact and flexible conveyor.

Automation: If the company pursues efficient and automated loading and unloading processes, it can choose a conveyor with functions such as automatic telescopic, automatic leveling, and linkage with other equipment.

In order to ensure the long-term and stable operation of the telescopic belt conveyor, regular maintenance and care are essential:

Regular inspection: Regularly check the wear of the conveyor belt and replace damaged parts in time to ensure the conveying effect.

Cleaning and maintenance: Keep the conveyor clean to prevent dust and debris from affecting the performance of the equipment.

Lubrication system: Regularly add lubricating oil to the moving parts to reduce friction and extend the service life of the equipment.

Electrical system inspection: Regularly check the motor and control system to ensure their normal operation.

The price of the telescopic belt conveyor for truck loading and unloading mainly depends on the equipment specifications, configuration and functional requirements. Basic small machines usually use standard steel and basic control systems, which are suitable for routine loading and unloading operations in small and medium-sized logistics sites; mid-range models are equipped with wear-resistant conveyor belts and intelligent weighing systems, which are suitable for industrial scenarios that require precise measurement; high-end customized models use imported motors, hydraulic lifting systems and remote monitoring functions to meet the stringent operating requirements of large ports or mines. Key factors affecting price include conveying length, bandwidth, power configuration (electric/diesel) and additional functions (such as dust removal system, explosion-proof design, etc.). We provide a variety of configuration options to ensure that customers get the best cost-effective solution based on actual operating needs and budget.

Telescopic belt conveyor is an indispensable automation equipment for modern logistics loading and unloading operations. Through its ingenious design, it solves many problems in traditional truck loading and unloading operations. With its high speed, safety, labor saving and flexibility, it greatly optimizes the loading and unloading process, reduces operating costs and enhances the core competitiveness of enterprises.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!