Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Portable Mobile Concrete Belt Conveyor is a mobile conveying equipment designed for construction sites, small concrete pouring and narrow space construction. It combines the advantages of lightweight structure, rapid deployment and efficient conveying, breaking the limitations of traditional conveying equipment, and is suitable for commercial concrete distribution, floor pouring, tunnel construction and other scenarios. The lightweight design is combined with a universal wheel/track chassis, and the installation can be completed in 10 minutes.

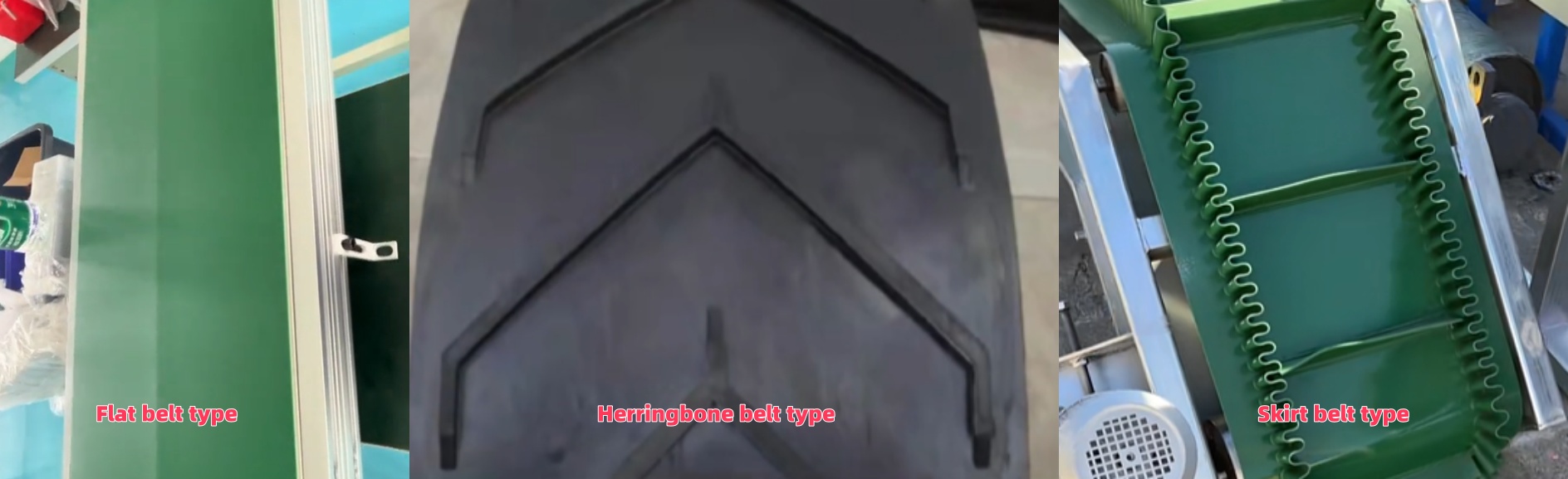

There are many types of portable mobile concrete belt conveyors. The following are some common classifications.

Flat belt type: The conveyor belt surface is flat, the structure is simple, and the cost is low. It is suitable for occasions with a small conveying inclination angle. The maximum inclination angle generally does not exceed 20°. It is more common in some ground construction scenes that do not require high conveying angles.

Herringbone belt type: There are herringbone patterns on the conveyor belt, which can increase the friction between the material and the conveyor belt. It is suitable for conveying with a certain inclination angle. The maximum inclination angle can reach about 27°. It is often used in construction sites that need to climb or downhill to convey concrete.

Skirt belt type: also known as trough belt, the conveyor belt has skirts or baffles on the edge to prevent materials from sliding during conveying. It can adapt to larger inclination angles, up to 45°. It is suitable for concrete conveying in various complex terrains and construction environments.

Portable mobile concrete belt conveyors are known for their lightweight design and flexibility. Its main features are as follows.

Flexible mobility: equipped with heavy-duty universal wheels or crawler chassis, it can be easily transferred to meet the needs of different construction sites.

Quick installation: modular design, it can be assembled and put into use in 10-15 minutes.

High-speed conveying: conveying capacity 10-60m³/h, conveying distance 5-30 meters (customizable and extended).

Strong adaptability: supports horizontal or inclined (≤45°) conveying, optional electric or diesel drive.

The portable mobile concrete belt conveyor operates on the principle of belt drive. The motor in the drive device reduces the speed and increases the torque through the reducer, transmits the power to the active roller, and drives the conveyor belt to circulate. The concrete material is placed on the conveyor belt, and moves along the belt surface in the specified direction by relying on the friction between the belt and the material and the blocking effect of the baffle. When the concrete is transported to the end, it is unloaded by gravity and the inertia of the belt movement.

Portable mobile concrete belt conveyors are widely used in scenes such as construction sites, infrastructure projects, and prefabricated component plants.

Foundation pouring: Concrete delivery, especially for large foundation plates or areas that are difficult to unload directly.

Backfilling of walls and columns: Concrete or backfill soil is delivered to the formwork or foundation pit.

Floor slab and roof pouring: Concrete is delivered to higher floors or flat roofs.

Basement and tunnel projects: Material transportation in confined or confined spaces.

Landscaping and earthwork projects: Transport soil, sand and gravel, etc.

Demolition projects: Transport construction debris and garbage.

Road and bridge repair: small-scale concrete repair and pouring.

Portable mobile concrete belt conveyors provide higher efficiency and flexibility than traditional conveying methods. The main differences are as follows.

|

Comparison Items |

Portable Belt Conveyor |

Manual Cart/Pumping |

|

Efficiency |

30m³/h (Continuous Operation) |

5-8m³/h (Intermittent Operation) |

|

Manpower Requirement |

Operated by 1-2 people |

4-6 people for handling |

|

Adaptability |

Adjustable angle and position |

Limited by the flatness of the site |

|

Cost |

One-time investment, labor-saving in the long term |

High continuous labor cost |

In order to ensure the long-term and reliable operation of portable mobile concrete belt conveyors, regular maintenance and care are essential:

Regular inspection: Regularly check the wear of the conveyor belt to ensure that it operates in good condition.

Cleaning equipment: Clean the equipment in time after use to prevent concrete residue from affecting normal operation.

Lubrication maintenance: Regularly add lubricating oil to moving parts to reduce friction and extend the service life of the equipment.

Electrical system maintenance: Regularly check the motor and electronic control system to ensure their normal operation and avoid downtime due to faults.

With its unique flexibility, high efficiency and economy, portable mobile concrete belt conveyors effectively solve many construction problems that traditional concrete conveying methods are difficult to deal with. It not only improves work efficiency, reduces costs and labor intensity, but also enhances the safety of operations. It is an indispensable assistant in modern construction, especially in complex or restricted working conditions.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!