Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

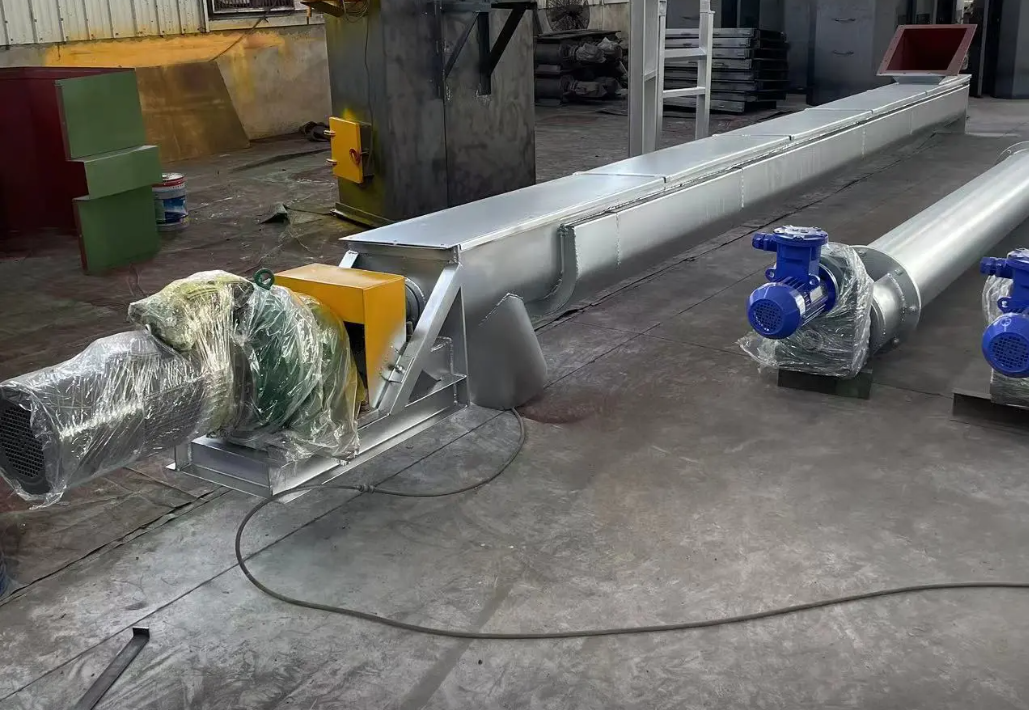

Screw Conveyer For Sand is a continuous conveying equipment designed for abrasive materials such as sand, gravel, slag, etc. It uses spiral blades to push sand and gravel forward. Due to the characteristics of sand and gravel themselves, closed screw conveyors are generally used for transportation. With its unique design and excellent performance, it has become a reliable choice for bulk material transportation and provides stable and efficient material transportation solutions for various projects.

It uses the rotation of spiral blades as the core power to accurately transport bulk materials such as sand, cement, and coal powder from one place to another, becoming an indispensable "invisible artery" in modern industrial automation processes.

Sand and gravel screw conveyors are mainly divided into three types: hose screw conveyors, horizontal screw conveyors, and vertical screw conveyors according to different structural forms and conveying directions.

Hose screw conveyor: Spring steel spiral shaft with wear-resistant blades, covered with cow tendon hose, has both flexibility and wear resistance, can be driven by electric, motor, and diesel, and can be 3-30 meters in length, which is more suitable for medium and low abrasive sand and gravel transportation.

Screw conveyor: It uses a rigid screw shaft and solid/belt wear-resistant blades, with a U-shaped groove or round tube metal shell, and can convey up to 200 tons/hour. The standard length is 3-30 meters, and multiple sections can be extended to 100 meters in series. It is often used in scenes such as sand and gravel aggregates entering mixers, mining gravel transportation, and port loading and unloading.

Belt conveyor: The sand and gravel belt conveyor has become the core transportation equipment with its stable and reliable performance. It consists of a drive device, a conveyor belt and other components. The belt is driven by a motor to drive the drive roller to realize sand and gravel transportation. The belt width is 500mm-2000mm optional, and the conveying capacity is hundreds to thousands of tons per hour.

When conveying sand and gravel, the sand and gravel screw conveyor has the remarkable characteristics of strong conveying capacity, wear resistance and durability, flexible layout, and energy saving.

Its specifications are diverse, and the conveying volume can reach 5-30 cubic meters per hour, which can meet the needs of projects of different scales; the key components are made of high-strength wear-resistant materials, and the specially treated spiral blades and wear-resistant liners can effectively cope with the wear caused by high hardness and irregular particles of sand and gravel, and adapt to harsh working conditions; the equipment supports multiple conveying modes such as horizontal, inclined, and vertical, and the modular design is easy to install and disassemble; the fully enclosed structure reduces dust spillage, and the reasonable design reduces energy consumption. It is also equipped with safety devices such as overload protection to ensure safe operation and environmental friendliness.

The sand and gravel screw conveyor drives the screw shaft through the motor, and uses the rotation of the spiral blade to generate axial force to push the sand and gravel from the feed port to the discharge port in the closed trough or hose for continuous conveying. At the same time, the trough or hose can prevent sand and gravel from spilling and dust from flying.

The sand and gravel screw conveyor solves the transportation problem with customized solutions. Three real cases show its strong performance and high adaptability!

Sand conveying project for construction sites: When construction sites are under construction, sand needs to be conveyed quickly and stably. The customer selected a U-shaped screw conveyor with a diameter of 200mm and a length of 3.5 meters for inclined sand conveying. In actual use, the conveyor can convey 10 tons of sand per hour with a stable conveying speed, meeting the construction site's demand for sand conveying.

Sand and gravel production line conveying project: The sand and gravel production line processes limestone and has an hourly output of 300 tons. The production line is equipped with crushers, feeders, vibrating screens and other equipment. In the production process, the sand and gravel screw conveyor undertakes the important task of conveying crushed sand and gravel and other materials from one place to another, such as conveying materials from the crusher to the vibrating screen, or conveying qualified sand and gravel after screening to the transport vehicle.

Sand and gravel powder conveying customized project: Some customers have reported that they need a screw conveyor for sand and gravel powder conveying, requiring an output of up to 1 ton per hour, a length of 2.5 meters, an inclination of 45°, a pipe diameter requirement of 225mm, and the equipment material is stainless steel.

The fully enclosed structure of the sand and gravel screw conveyor effectively prevents dust from spilling out, and can be arranged horizontally, tilted or vertically to meet the needs of different sites. The equipment operates stably and reliably, and is widely used in construction sites, quarries, concrete mixing plants and other occasions. It is an ideal solution for the efficient transportation of sand and gravel materials.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!