Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Hand Flexible Screw Conveyor adopts a high-elasticity coil spring design, which can easily convey powdered, granular and small-granular block materials (such as feed, flour, chemical powder, etc.). It is purely manually operated and adaptable to non-electrical environments; it is flexible and bendable, supporting horizontal to 30° inclination conveying; lightweight design, efficiency is more than 3 times higher than manual, and it is an ideal conveying tool for small farms, laboratories, and temporary construction sites!

Hand Flexible Screw Conveyor We offer flexible spiral hoses (starting at 113mm in diameter) that deliver material conveyance at speeds of 0.5-3m³/h. This allows for short-distance transport of bulk materials such as grain and feed without the need for electric drive. Its wear-resistant hose adapts to narrow spaces and facilitates quick loading and unloading.

The Hand Flexible Screw Conveyor is suitable for granular/powder materials. It is easy to operate, does not require electrical control, and delivers accurately without spillage. It is simple to maintain and has low cost. It is more efficient in confined spaces and multi-scene transportation.

No electricity required: There is an optional motor for oil extraction machines, suitable for outdoor or power-inconvenient environments.

Lightweight and flexible: The whole machine weighs 15-30kg, can be carried by one person, and can be deployed quickly.

Strong adaptability: The flexible spiral can be bent to adapt to conveying at different angles (horizontal or small inclination).

Wide range of uses: Suitable for conveying various powders, granules, and small block materials, such as grains, feed, seeds, plastic granules, chemical powders, small granular fertilizers, etc.

|

Model |

Length (Meters) |

Pipe diameter |

Loading Capacity |

Motor phase |

Installation |

Structure |

Conveying height |

|

RLS100 |

3-30 |

100mm |

5-8 |

Single phase 3kw |

Vehicle mounted |

Steel screw blade inside |

Depend on case |

|

RLS120 |

120mm |

10-15 |

Three phase 4kw |

||||

|

RLS160 |

160mm |

15-20 |

Three phase 5.5kw |

||||

|

RLS180 |

180mm |

20-30 |

Three phase 11kw |

When the operator turns the handle, the drive shaft drives the flexible spiral blade to rotate in the conveying pipe. The rotating motion of the spiral blade pushes the material from the feed port to the discharge port, realizing continuous material transportation. Due to the flexible characteristics of the spiral blade, the conveying pipe can be bent and arranged according to the actual working environment, and can easily cope with vertical lifting, horizontal conveying, or inclined conveying. During the conveying process, the material is pushed by the spiral blade and moves along the inner wall of the conveying pipe, so that it is stably conveyed to the designated position.

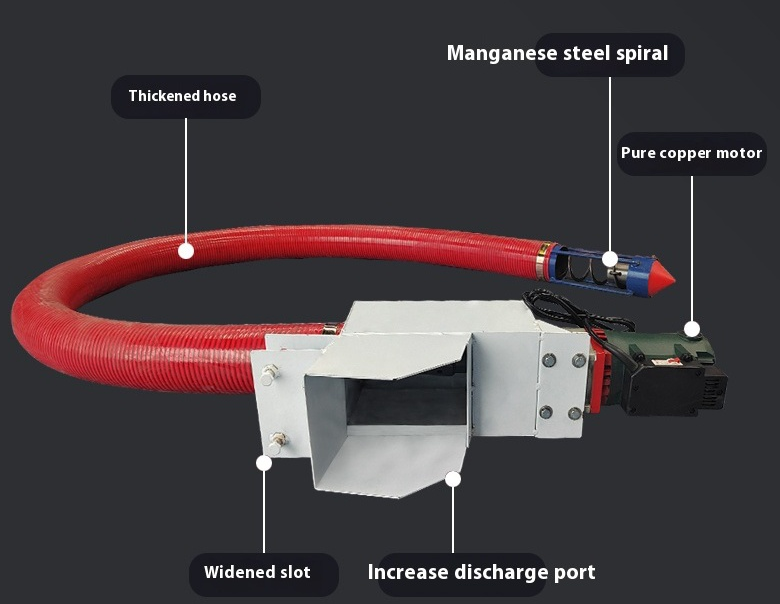

The Hand Flexible Screw Conveyor consists of an ergonomic handle, wear-resistant flexible spiral blades, flexible conveying pipes, and inlet and outlet ports. Its modular design makes it easy to assemble and disassemble, and is suitable for material conveying needs in various scenarios.

Flexible conveying pipe: This is its most significant feature. It is usually made of wear-resistant polymer material, with a smooth interior and a certain degree of curvature, which can adapt to different conveying paths.

Internal spiral (or auger): A continuous spiral blade rotates inside the conveying pipe to push the material forward.

Manual crank: Gear transmission, labor-saving design, shaking can drive the spiral to rotate.

Drive motor: Usually a small motor that provides power for the spiral rotation.

Inlet and outlet: Used for loading and unloading materials respectively.

The Hand Flexible Screw Conveyor can quickly convey granular and powdery materials such as grain and flour. It is suitable for conventional materials such as seeds and feed, meeting the material conveying needs of multiple industries.

Powdered materials: flour, milk powder, feed additives, chemical powder, etc.

Granular materials: grains, seeds, plastic particles, small nuts, etc. (particle size ≤10mm).

Light block materials: soft blocks after crushing (such as feed blocks, wet clay).

The Hand Flexible Screw Conveyor solution is available with various power sources, including electric motors, motors, and diesel. Electric motors are suitable for stationary applications, motors are suitable for environments without power, and diesel models handle heavy loads, balancing flexible conveying with diverse application needs.

Electric motor drive: Suitable for stationary applications, single-phase or three-phase asynchronous motors (power 0.5-2.2kW) are available. The screw conveyor is linked to the conveyor through a reduction mechanism, providing stable conveying with low energy consumption, making it suitable for small-batch material transfer within a workshop.

Motor drive: Utilizing a DC motor and battery power, the Hand Flexible Screw Conveyor is highly portable and suitable for temporary outdoor conveying without an external power source, such as short-distance material loading on farms and construction sites.

Diesel power: For heavy-load, long-duration operations, the Hand Flexible Screw Conveyor offers an optional small diesel engine with powerful power to drive the flexible screw conveyor over long distances. It is suitable for heavy-load applications such as mining and infrastructure construction, and is highly capable of handling harsh environments.

The Hand Flexible Screw Conveyor is suitable for transporting feed/seeds on farms, transferring powder samples in laboratories, and delivering raw materials in food processing. It can adapt to different scenarios and transport different types of materials.

Small farms: Grains and pellet feed can be quickly and accurately transported from the warehouse to the feeding trough, completely saying goodbye to the spillage loss of traditional manual handling; in the sowing process, it can achieve quantitative delivery of seeds, greatly improving planting efficiency.

Laboratory research: The equipment undertakes the important task of safe transportation of powder samples and granular materials. Whether it is dust-free transportation of chemical powders and pharmaceutical raw materials, or precise measurement of small batches of granular materials such as catalysts and desiccants, it can effectively avoid dust pollution and manual errors.

Food processing: In food processing scenarios such as small bakeries and candy workshops, manual flexible screw conveyors rely on their hygienic and convenient characteristics to achieve closed transportation of raw materials such as flour and powdered sugar.

Flexible helper for building decoration: In the face of narrow spaces and temporary operation needs, manual flexible screw conveyors can be flexibly arranged to transport cement, mortar, gypsum powder and other building materials over short distances, significantly reducing manpower consumption and handling intensity.

When choosing a suitable Hand Flexible Screw Conveyor, we can combine the following requirements with our own conveying scenarios and transportation scenarios to make a choice.

Material adaptability: Select the model according to the material characteristics (powder, granule or soft block material). Powders need to be sealed and dustproof. Granular materials require a spring spacing of ≤10mm to avoid high viscosity and long fiber materials.

Parameter and cost balance: The approved conveying volume (0.1-0.5t/h), distance (2-15 meters) and inclination (≤30°), the larger the pipe diameter and the longer the distance, the higher the cost.

Scenario verification and pit avoidance: Before purchasing, the spatial adaptability of the equipment needs to be verified (bending radius ≥5 times the pipe diameter), and models with a pipe diameter of <50mm should be avoided.

Hand Flexible Screw Conveyor Pricing depends primarily on the material, specifications, and features. The basic carbon steel + PVC model is economical and suitable for general material conveying. The 304 stainless steel model is 30%-50% more expensive but offers corrosion resistance, meeting the requirements of industries like food and chemicals. This equipment offers optional value-added features such as labor-saving gears and quick-release interfaces. We can recommend the most cost-effective solution based on frequency of use and environmental requirements (such as rust prevention and hygiene standards).

Hand Flexible Screw Conveyor plays an important role in many fields with its unique advantages. Whether it is small-scale production and processing or temporary material conveying operations, it can provide users with efficient, convenient and economical material conveying solutions.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!