Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Bucket Elevator Type E16 is designed for vertical conveying of granules, powders and small pieces of materials. It adopts high-strength chain/belt drive, with a lifting height of up to 50 meters and a processing capacity of 5-100t/h, meeting the large-scale production needs of grain, building materials, chemical and other industries. It supports customized configurations such as variable frequency speed regulation and explosion-proof design, adapts to harsh working conditions such as high temperature and corrosion, and saves 40% energy compared with traditional conveying methods.

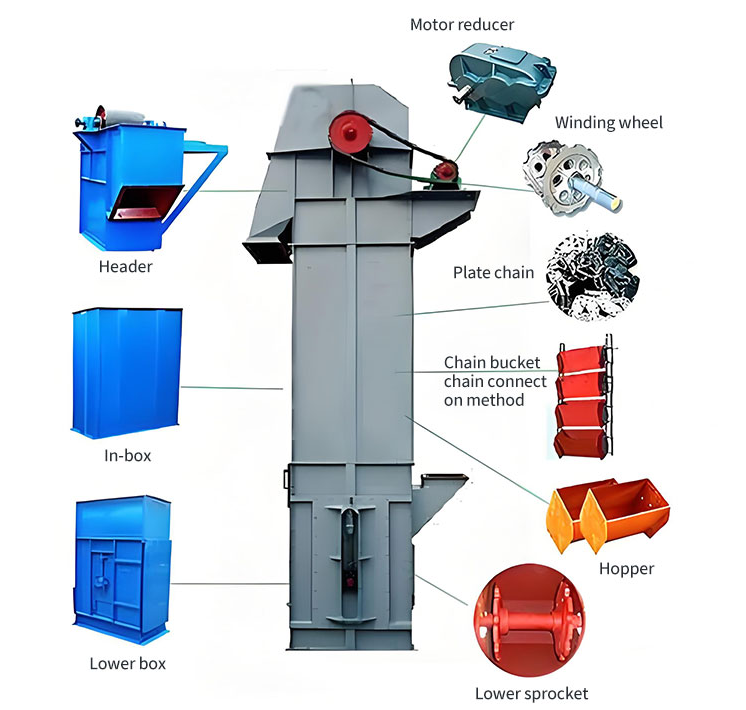

With the drive device, traction components, hopper and casing as the core, it realizes stable and low-consumption vertical lifting of materials through motor drive, chain/belt traction, and special hopper and closed casing.

Hopper: polyethylene (PE) or 304 stainless steel, volume 0.5-20L/bucket;

Traction parts: alloy steel chain/belt, wear-resistant and tensile-resistant;

Drive device: reduction motor (7.5-55kW), optional variable frequency control;

Casing: carbon steel or stainless steel fully sealed structure, dustproof and rainproof.

When the E16 bucket elevator is working, the material is loaded into the hopper from the bottom feed port with the help of gravity or a material-dispensing device. The chain or belt drives the hopper to rise vertically. After reaching the top, the material is discharged under the action of centrifugal force and gravity, and the empty bucket circulates back to the bottom, forming a continuous material conveying process.

High-precision quantitative, low-consumption noise reduction, wear resistance and impact resistance, with intelligent monitoring and flexible adaptability, it can easily cope with particle/powder conveying in multiple industries. Customized design meets complex working conditions.

Large conveying capacity: The maximum processing capacity of a single machine is 100t/h, which meets the needs of industrial production;

Energy-saving and high-efficiency: The energy consumption is 40% lower than that of traditional pneumatic conveying;

Stable and reliable: heavy-duty chain design, failure rate <1%;

Multi-material adaptation: particles (grain, ore), powder (cement, fly ash), small pieces (coal);

Flexible customization: support special working condition designs such as explosion-proof, high temperature resistance, and corrosion resistance.

|

Parameter |

E16 Standard Type |

Custom Extended Type |

|

Lifting Height |

10-50 meters |

≤80 meters (requires segmented design) |

|

Hopper Capacity |

5L per hopper |

0.5-20L per hopper (optional) |

|

Conveying Capacity |

20-50t/h |

5-100t/h (adjustable) |

|

Power Configuration |

7.5-37kW motor |

Explosion-proof/frequency conversion motor (optional) |

|

Material Options |

Carbon steel/304 stainless steel |

316 stainless steel/abrasion-resistant liner (optional) |

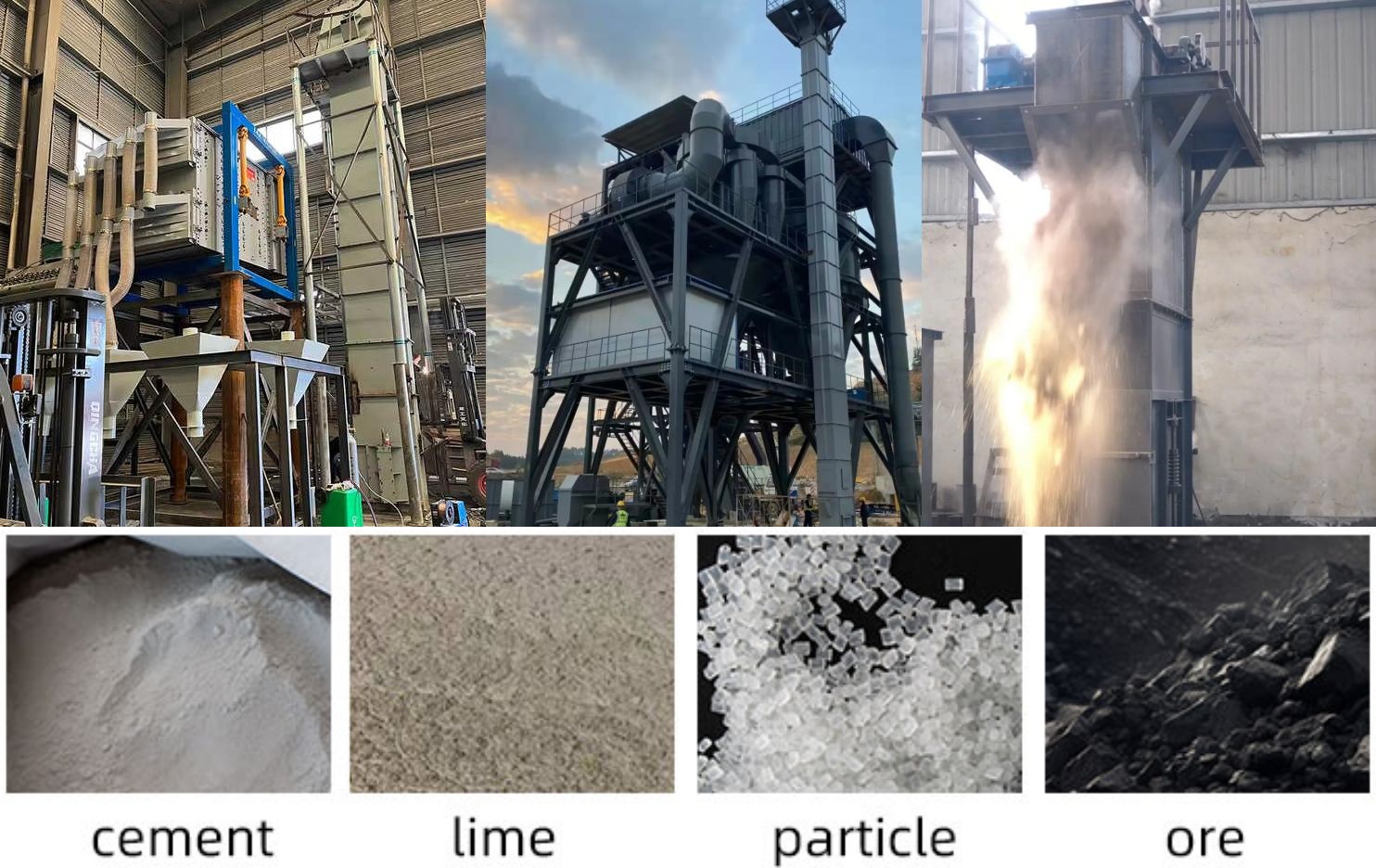

E16 bucket elevator is widely used in wheat, corn, cement, fly ash, fertilizer, mines, etc., achieving 5-100t/h efficient vertical transportation, and is a reliable choice for improving the level of production automation!

Grain processing industry: used for vertical lifting of flour, grains, and beans, often used in conjunction with crushers and mixers.

Building materials industry: suitable for lifting powders such as cement, gypsum powder, and fly ash. The fully enclosed casing is equipped with a dust removal interface to solve the problem of dust pollution.

Chemical industry: On the production lines of fertilizers, plastic particles, and pharmaceutical intermediates, the stainless steel E16 elevator can meet the requirements of sanitary transportation and avoid cross-contamination of materials.

The selection needs to comprehensively consider the lifting height, material characteristics, processing capacity, material and special needs. By accurately matching the working parameters, ensure the efficient and stable operation of the equipment and maximize the return on investment!

Material characteristics: Select the belt strength according to the stacking density (such as wheat 0.75t/m³, cement 1.3t/m³); materials with a moisture content of >15% need to use a chain traction structure to prevent slipping.

Lifting height: The standard model has a lifting height of 3-15 meters. When it exceeds 10 meters, an intermediate support device must be installed to ensure operational stability.

Environmental requirements: Explosion-proof motors and anti-static tapes are required for flammable and explosive sites, and stainless steel hoppers and anti-corrosion coatings should be used in humid environments.

The price of the E16 bucket elevator varies depending on the configuration, mainly affected by factors such as lifting height, material selection (carbon steel or stainless steel), and special functional requirements (such as explosion-proof, wear-resistant, and automated control). The basic model is suitable for conventional industrial scenarios, while the cost of models with food-grade stainless steel or high wear-resistant configurations is relatively high. The manufacturer provides whole machine warranty and extended warranty service for core components, and supports non-standard customization. Users can choose the most suitable cost-effective solution according to actual production needs and budget to ensure long-term stable operation and efficient production of the equipment.

The E16 bucket elevator provides a cost-effective vertical conveying solution for small and medium-sized industrial enterprises with its "small and exquisite" technical characteristics. With the development of industrial automation, this model is gradually upgrading to modular design (such as quick-detachable housing and tool-free maintenance structure). In the future, it will further reduce installation and commissioning time and maintenance costs, and become a standard equipment for vertical material handling in more industries.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!