Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Inclined shaftless screw conveyor is designed for 15°-75° inclination conditions. It adopts a shaft-free anti-winding structure to easily deal with the transportation of viscous or fragile materials such as sludge, chemical particles, and food.

Type: Single shakeless/Double shakeless

Diameter: 150 - 470 mm

Installation inclination: 0-15° or 0-30°

Length: 0-20 m or 0-30 m

Production: 0.8 t/h - 45 t/h

Power: 0.55 kW - 5.5 kW Speed: 29 rpm

Structural material: Carbon steel, 304/316 stainless steel

Incination: ≤45°

Application range: Kitchen waste, animal manure, powder, coal powder, soybean, corn, calcium carbonate, titanium dioxide, food additives.

Inclined shaftless screw conveyor is an innovative conveying equipment designed for large-angle working conditions. It adopts a center-shaftless structure, breaking through the 35° inclination limit of traditional conveyors, and can achieve 15°-45° inclined conveying, perfectly solving the problem of climbing conveying of sticky and easily entangled materials. The fully enclosed design prevents dust spillage, and is a smart choice to replace traditional belt conveyors and bucket elevators!

Inclined shaftless screw conveyor has a shaftless design to prevent winding, and variable pitch blades prevent slipping and backflow. The efficiency of 30° inclination exceeds 90% of horizontal conveying; it is well sealed to prevent pollution and is suitable for many types of complex materials.

Anti-slip and anti-backflow: It adopts an integral shaftless spiral blade, which fits tightly with the trough body. The "wrapped push" of the blade on the material is used to offset the influence of gravity. The conveying efficiency can still reach more than 90% of horizontal conveying at a 30° inclination.

Anti-entanglement and adaptability to complex materials: Materials containing fiber or blocky impurities such as straw, vines, and construction waste are easy to entangle the central shaft and cause jamming during inclined transportation. The inclined shaftless screw conveyor eliminates the central shaft, and the spiral blades are directly connected to the drive device to avoid the risk of entanglement from the root.

Sealed and wear-resistant design: In view of the problem that materials are easy to leak and equipment is easy to wear during inclined transportation, the equipment adopts a fully enclosed U-shaped trough + flip-top sealing cover, and semi-enclosed or fully enclosed mode can be selected according to needs.

Multi-functional adaptation: The material can be selected from 304/316L stainless steel, wear-resistant steel, and polymer lining, and can be equipped with explosion-proof, sealing, heating/cooling and other modules.

The maximum inclination angle of the inclined shaftless screw conveyor can reach 45°, which can effectively offset the influence of gravity and ensure stable material transportation.

The maximum design inclination angle is 45°: at this angle, the material transportation efficiency can be ensured to be ≥85%, and there is no problem of slippage and reflux, and the energy consumption is only increased by ≤20%. The equipment adopts a shaftless anti-winding structure, which is particularly suitable for the inclined lifting of viscous materials such as chemical powders and sludge.

Customized design can be expanded to 75°: key technologies include variable pitch blades, anti-slip linings and double helix structures, which can meet the needs of special working conditions such as limited space. When selecting, it is necessary to comprehensively consider the moisture content, viscosity and other characteristics of the material. We provide free inclination angle testing and solution optimization services.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

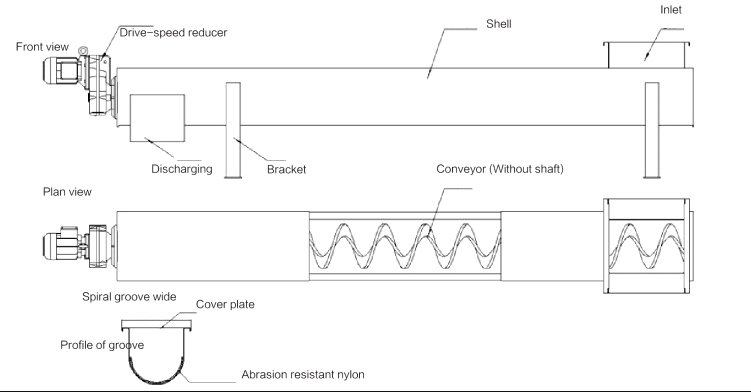

The inclined shaftless screw conveyor uses the rotating shaftless spiral blade as the core driving component. The motor drives the cycloidal pinwheel reducer to rotate continuously in the U-shaped or tubular trough. Under the dual action of its own gravity and the friction of the trough, the material moves axially along the "bolt" like a "nut" to achieve continuous transportation.

Inclined shaftless screw conveyor is specially designed for conveying powdered, granular and bulk materials. It can transport a variety of materials such as grain, ore, plastic granules, etc. The inclination angle can be adjusted from 0° to 45°. It adopts a screw-free anti-blocking structure and wear-resistant material to ensure long-term use.

Viscous and entangled materials: such as sewage treatment plant sludge, chemical sludge, oily sludge, etc. In addition, it can also transport kitchen waste, animal feces, fermented organic fertilizer, wood chips, straw, pulp, and textile waste.

Powdered and granular materials: The equipment can stably transport various powdered and granular materials, including chemical raw materials PTA particles, PVC powder, calcium carbonate, titanium dioxide, food additives, starch, powdered sugar, milk powder, seasonings, as well as mineral powder, coal powder, tailings sand, and quartz sand.

Fragile or lightweight materials: For fragile or gently handled materials, such as soybeans, corn, and potato chips, the equipment can run at a low speed to reduce breakage; lightweight materials, foam particles, and plastic sheets can be prevented from flying through a closed design to ensure a stable and efficient conveying process.

Materials with special properties: For corrosive materials, high-temperature materials, or materials containing trace amounts of liquid, 316L stainless steel, plastic-lined materials, or leak-proof structures can be customized to adapt to harsh working conditions. However, it is not suitable for pure liquid, super-large block or super-viscous elastic materials, and the selection and optimization should be based on the specific characteristics.

The core of the design of the inclined shaftless screw conveyor is to offset the adverse effects of gravity on material transportation through structural optimization, and at the same time use the shaftless characteristics to solve the winding problem and achieve stable transportation at a large inclination angle.

Mechanical balance design: During inclined transportation, the material generates a downward component force along the inclined surface due to gravity, which is easy to cause slippage and reflux. The equipment constructs a gradient thrust through variable pitch spiral blades, forms an axial extrusion force by compressing the material, and uses the friction between the spiral blades and the material to convert it into an upward thrust force to offset the gravity component.

Shaftless structure: Abandoning the central axis design of the traditional shaft spiral, the integral spiral blade is directly connected to the drive device, and the blade is continuous spiral without breakpoints. This structure fundamentally avoids the problem of fibrous and ribbon materials winding around the central axis.

Optimized sealing and adaptability: U-shaped trough + openable and closable sealing cover structure is adopted, and semi-closed or fully closed mode is selected according to the inclination angle and material characteristics to prevent material leakage during inclined conveying, especially suitable for polluting and volatile materials.

Material and angle adaptation: The blade material is selected from wear-resistant steel, stainless steel (etc.) according to the material characteristics to ensure that the blade is wear-resistant and impact-resistant in the inclined state; the design inclination angle range is usually 15°-45°. When it exceeds 30°, the thrust can be further enhanced by increasing the blade speed or reducing the pitch gradient to achieve dynamic balance at different inclination angles.

The inclined shaftless screw conveyor can be used in different industries. The following are the results of customers in different industries.

Sewage treatment plant sludge lifting: A 45° inclined shaftless screw conveyor is used to replace the traditional belt conveyor to successfully solve the slippage and inefficiency problems when conveying sludge with a moisture content of 80%. The equipment is equipped with wear-resistant linings and variable frequency speed regulation functions to achieve 15m³/h stable conveying.

Chemical plant PTA particle conveying: In response to the special needs of PTA particles that need to be lifted vertically by 10 meters, a chemical plant selected a 60° large-angle customized model using 316L stainless steel. This solution perfectly adapts to space limitations and achieves 8t/h dust-free and closed conveying.

Food factory conveying: In order to protect fragile food, a 30° low-speed inclined model is selected, and food-grade 304 stainless steel is used to ensure hygiene and safety. This solution reduces the product breakage rate from 5% to 0.3%, and is also easy to clean and maintain.

Dahan screw conveyor manufacturer has focused on the research and development and production of inclined shaftless screw conveyors for more than ten years. It has a professional team and mature technology. The equipment uses High-quality materials such as 304/316L stainless steel/carbon steel are suitable for customers' application scenarios, and have both corrosion resistance and wear resistance and structural stability. It supports non-standard customization of 15°-45° inclination angles, different conveying volumes and special working conditions. The pitch, lining material and sealing method can be adjusted as needed to fully meet customers' personalized conveying needs. It is a reliable supplier of inclined material transfer equipment.

In industrial production, when materials need to be transferred from low to high, traditional conveyors often face problems such as slippage, backflow, and blockage. The inclined shaftless screw conveyor has become an ideal equipment for handling viscous, fibrous, and impure materials with its unique structure and targeted design without a center shaft.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!