Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

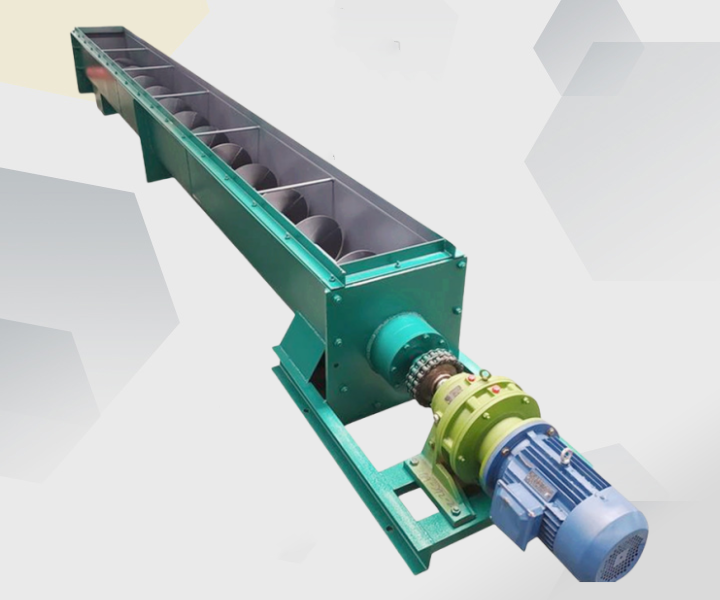

Industrial shaftless screw conveyor is a continuous conveying equipment with no central shaft design. It uses wear-resistant spiral blades to rotate in a U-shaped groove or pipe to push sticky, easy-to-entangle or fiber-containing materials forward.

Type: single shaftless/double shaftless

Diameter: 150 - 470 mm

Installation angle: 0-15° or 0-30°

Length: 0-20 m or 0-30 m

Output: 0.8 tons/hour - 45 tons/hour

Power: 0.55 kW - 5.5 kW Speed: 29 rpm

Angle: less than 40 degrees

Structural material: carbon steel, hot-dip galvanizing, 304/316 stainless steel, hardened alloy, etc.

Industrial shaftless screw conveyor breaks through the traditional limitations with its innovative centerless structure. It uses high-strength wear-resistant steel spiral blades and customized linings to easily handle complex materials such as sludge, fiber, and particles, and has excellent anti-winding and anti-blocking performance. The fully enclosed design combined with intelligent frequency conversion drive achieves low energy consumption and high-precision transportation. The maximum capacity of a single machine is 458m³/h, and the tilt angle supports flexible adjustment from 0° to 40°.

Industrial shaftless screw conveyors are mainly divided into U-type and tubular types. The U-type trough is open for easy observation and cleaning; the tubular type is fully enclosed to prevent leakage and dust.

U-type shaftless screw conveyor: The trough is U-shaped and open, the top can be covered and sealed, the bottom is arc-shaped, the spiral blades directly push the material, equipped with a removable wear-resistant lining, and there are support brackets on both sides of the trough, which is suitable for horizontal or ≤15° small angle tilt transportation. It can handle sticky, fibrous, easy-to-cake and granular materials. The open trough is easy to observe and clean, and the U-shaped design can stir and break light lumps.

Tubular shaftless screw conveyor: The trough is a closed round tube, the spiral blades rotate in the tube, the flanges at both ends are sealed, and it is equipped with an anti-blocking detection device, which is suitable for long-distance or vertical lifting. It is suitable for liquid, moist, dusty and toxic/flammable materials. The fully sealed structure prevents leakage and dust. It can be transported at a large angle of ≤30° or vertically ≤6 meters, and the horizontal distance exceeds 30 meters. It is suitable for small and medium-sized closed transportation.

The industrial shaftless screw conveyor has significant advantages. The shaftless design prevents winding, has high conveying efficiency, low energy consumption, simple maintenance, and is suitable for working conditions in multiple industries.

Anti-blocking design: The shaftless structure completely solves the winding problem of traditional screw conveyors, and is suitable for conveying sludge, kitchen waste, chemical fiber waste, etc.

Long conveying distance: The conveying length of a single machine can reach 30 meters, and it can realize ultra-long-distance material conveying through multi-stage series connection. This feature makes it advantageous in cross-regional material allocation in large factory workshops, as well as long-distance material transportation scenarios such as mines and ports.

Customized design: The material, angle, length, etc. and some additional functions can be customized according to customer needs.

Materials that are easy to entangle and adhere: It can easily handle sludge, fiber impurities and other materials that are easy to clog and entangle the spiral shaft.

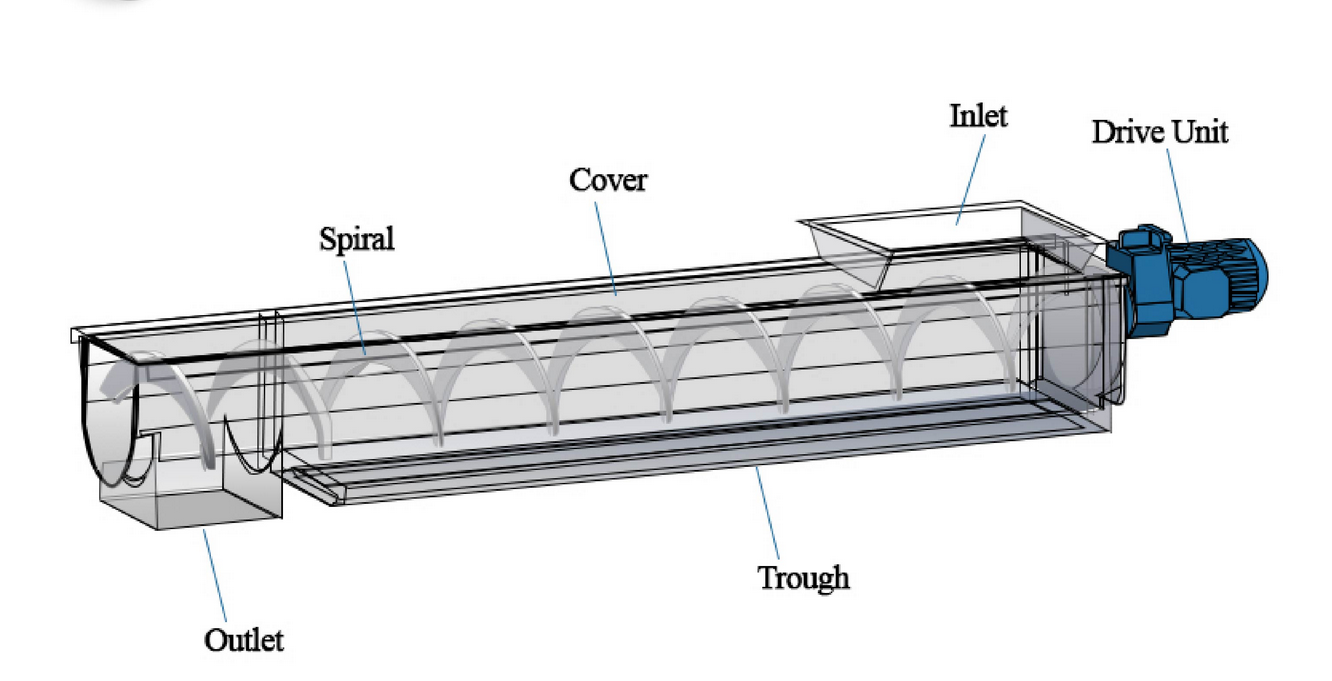

The core structure of the industrial shaftless screw conveyor revolves around the "no center shaft" design, and material conveying is achieved through the coordination of various components.

Spiral blades: It adopts an integral shaftless structure, made of wear-resistant steel or polymer materials, fixed to the drive shaft by welding or bolts, and the blade shape is designed according to the material characteristics to ensure uniform conveying thrust.

Drive shaft: Located at both ends of the spiral blade, it is fixed by the bearing seat to transmit rotational power. The shaft diameter is matched according to the conveying torque to ensure strength and stability.

Trough body: mostly U-shaped or O-shaped sealing structure, commonly used materials include carbon steel, stainless steel or corrosion-resistant coated steel plate.

Feed inlet and outlet: The feed inlet is mostly funnel-shaped, which is convenient for material introduction; the outlet is designed as a straight or oblique mouth according to the process requirements, and some scenes need to be equipped with a valve to control the flow.

The industrial shaftless screw conveyor realizes material transportation through the rotation of the spiral blade without a central shaft. The motor drives the spiral blade to rotate in the U-shaped or O-shaped trough body through the reducer, and uses the thrust of the spiral surface to push the material axially. When the spiral blade rotates, the material is affected by the thrust of the blade, the friction of the trough body and its own gravity, forming a continuous axial movement in the trough, thereby completing the transportation from the feed inlet to the outlet.

The conveying angle of industrial shaftless screw conveyors is usually 0° to 25°. Some models can support small angle conveying within 40°, but in actual applications, it needs to be determined in combination with material characteristics, equipment design and conveying efficiency.

Horizontal conveying: suitable for continuous and uniform conveying of loose, sticky or easily entangled materials such as sludge and kitchen waste. Its maximum conveying capacity can reach 458m³/h, with minimal energy consumption and easy maintenance.

Small angle tilt (10°-20°): suitable for scenes where space is limited and the material height needs to be raised or transported with equipment such as filter presses. It can achieve vertical fine-tuning of materials while ensuring efficiency.

Extreme angle (25°-40°): suitable for short-distance small-batch conveying or temporary scenes. It is necessary to reduce the screw speed and equip with anti-backflow devices such as check valves.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

The material selection of industrial shaftless screw conveyor needs to be comprehensively determined based on the characteristics of the conveyed material, environmental conditions and cost budget.

Core structure material: Spiral blades are mostly made of high-strength wear-resistant steel or stainless steel to ensure strength and deformation resistance when pushing materials.

Contact material: The conveying trough body and lining plate can be customized according to the material. For corrosive materials such as chemical raw materials, sewage sludge, etc., 316L stainless steel or fiberglass trough body is used, lined with polytetrafluoroethylene or rubber; for high-temperature materials such as metallurgical slag and hot ash, the trough body is made of heat-resistant steel, and the lining plate is equipped with high-aluminum ceramic or casting. For food/pharmaceutical grade materials, the whole machine is made of 304 stainless steel and polished.

Drive and seal material: The reducer housing is cast iron or aluminum alloy, taking into account heat dissipation and lightweight; the gears and shafts are carburized and quenched with alloy steel, and the wear resistance is better than ordinary steel. The shaft end seal adopts a double-layer mechanical seal with a fluororubber O-ring, which can achieve zero leakage in a wide temperature range of -30℃ to 150℃.

The industrial shaftless screw conveyor can quickly convey the following types of materials with its shaftless design and sealing structure.

Viscous and fibrous materials: can be used to transport sludge, kitchen waste, wine lees, pulp, animal feed containing straw fibers, etc. The shaftless design can avoid fiber entanglement, and the thrust of the spiral blades can overcome the viscous resistance of the material to ensure continuous transportation.

Materials that are easy to agglomerate or form a mass: suitable for wet coal powder, slaked lime, cement clinker, damp and agglomerated fertilizer particles, and dough and paste materials in food processing. The rotating thrust of the spiral blades can break up light agglomerations, and cooperate with the tank body to stir to prevent material accumulation.

Granular and loose materials: such as grains such as wheat and corn, beans, sand and gravel, coal ash, plastic particles, feed raw materials, etc. can all be transported. The maximum conveying capacity during horizontal transportation is 458m³/h, and the energy consumption is lower than that of a shafted spiral.

Liquid or wet materials: can handle wet coal sludge, tailings from coal washing plants, fruit residues with juice, slaughterhouse waste, etc. The sealed tank body prevents liquid leakage, and wear-resistant materials such as stainless steel resist moisture corrosion. Anti-backflow devices are required for inclined transportation.

|

Comparison Dimension |

Industrial Shaftless Screw Conveyor |

Industrial Shafted Screw Conveyor |

|

Core Structure |

No central shaft; spiral blades integrally welded or fixed to the drive shaft; U/O-shaped sealed trough. |

With central shaft; spiral blades fixed to the shaft; trough structure similar, with central shaft running through the entire length. |

|

Anti-Winding Capability |

★★★★★ (Shaftless design completely avoids winding of fibrous and strip-shaped materials) |

★★ (Central shaft is prone to winding by fibrous and long materials, requiring frequent cleaning) |

|

Conveying Efficiency |

Maximum horizontal conveying capacity up to 458m³/h; rotation speed needs to be reduced (≤60rpm) for inclined conveying. |

Horizontal conveying capacity is generally lower than shaftless models, with poorer adaptability to inclined angles. |

|

Sealing and Environmental Friendliness |

Fully enclosed trough + precision seals, excellent anti-leakage and dust-proof effects, compliant with food/chemical hygiene standards. |

Similar sealing structure, but the penetration part of the central shaft is prone to leakage, with high cleaning difficulty. |

|

Material Selection |

Carbon steel, 304/316L stainless steel, ultra-high molecular weight polyethylene (suitable for corrosive/anti-static scenarios). |

Mainly carbon steel; stainless steel is mostly used in the food industry, with weaker corrosion resistance. |

|

Application Scenarios |

Sewage treatment (sludge conveying), food processing (kitchen waste), chemical industry (corrosive waste), environmental protection (medical waste transportation). |

Agriculture (grain conveying), construction (sand and gravel), mining (dry tailings), general industrial powder transportation. |

Dahan Machinery is a professional industrial shaftless screw conveyor manufacturer with many years of industry experience. It provides 304/316 stainless steel and carbon steel wear-resistant linings and other material models, and supports 200-800mm non-standard customization and explosion-proof/food grade certification. Equipped with advanced production equipment to ensure ±0.5mm processing accuracy, free material testing and 3D solution design are provided, and customized models are completed in 15-20 days. It has served many well-known companies, supports non-standard customization, and can provide you with a perfect solution based on your on-site conditions.

In industrial production, material transportation is a key link to ensure production continuity. Traditional screw conveyors are prone to entanglement and blockage due to the central shaft design, and it is difficult to cope with the transportation needs of highly viscous and easily entangled materials. The shaftless screw conveyor has become a core equipment in the fields of chemical industry and food processing due to its innovative center shaft-free structure.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!