Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

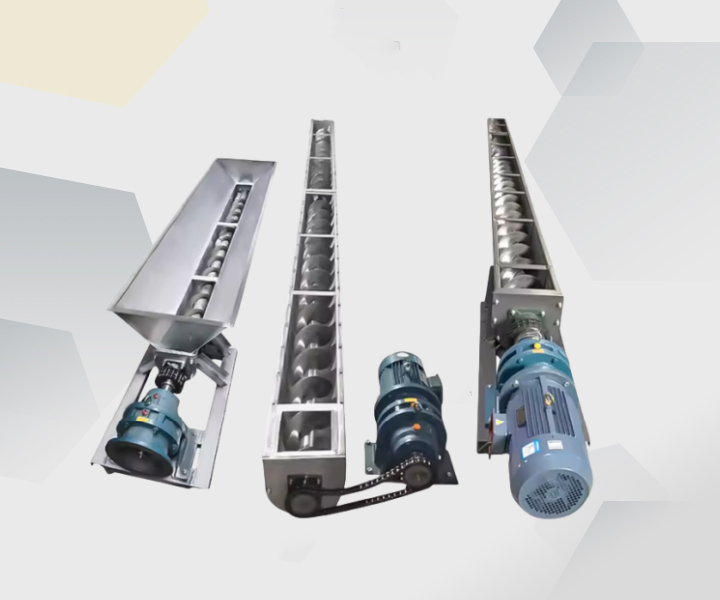

Biomass shaftless screw conveyor is an advanced conveying equipment designed for biomass fuel, agricultural and forestry waste, organic solid waste and other materials.

Price: $650.00-$3,560.00/set

Conveying capacity: 458 cubic meters/hour

Length: 30~70 meters

Speed: 13~140 rpm

Torque: 4000N/m

Material: Carbon steel/stainless steel

Pitch: Customizable according to customer needs

Mobility: Ability to add roller design

Applicable materials: Straw, sawdust, kitchen waste, wood chips, shavings, wood, debris.

Biomass shaftless screw conveyor is specially designed for agricultural waste, forestry residues, energy crops and organic solid waste. The shaftless spiral structure prevents straw and vine entanglement. The fully sealed trough is suitable for fluffy/sticky materials. The stainless steel material is corrosion-resistant and can quickly transport straw, wood chips, kitchen organic matter, etc. It is the core conveying equipment for biomass processing. We provide shaftless screw conveyors of different materials, types and inclinations. We can customize suitable conveying equipment for you according to your needs.

The center shaftless design prevents entanglement and is suitable for various types of biomass such as straw and wood chips; the fully sealed trough controls dust, and the wear-resistant lining reduces loss.

Excellent anti-entanglement ability: Biomass materials, such as straw, wood chips, vines and fiber debris in domestic garbage, often have strong entanglement. The biomass shaftless screw conveyor adopts an innovative center shaftless design, which completely eliminates the risk of the center shaft being entangled by materials.

Adapt to various materials with different characteristics: Biomass materials have various forms, including granular, powdery, semi-fluid, viscous materials, etc. The spiral blades of the shaftless screw conveyor are specially designed, which can be optimized according to the characteristics of the material, and the push can be achieved through a reasonable pitch design.

High-strength material: The spiral blades are made of wear-resistant alloy steel, 304/316 stainless steel or surface hardening treatment, and the wear resistance is increased by 3-5 times.

Replaceable lining: The tank body is lined with wear-resistant polymer materials or ceramic patches to extend the maintenance cycle.

Sealed conveying: The fully enclosed structure prevents dust from overflowing, meets environmental protection requirements, and reduces material loss.

Multi-angle installation: supports horizontal, inclined (≤30°) or vertical arrangement to meet the needs of different sites.

The biomass shaftless screw conveyor has a rich selection of materials. The basic model uses carbon steel, which is economical and practical; 304/316L stainless steel can be selected for conveying corrosive materials, which is rust-resistant and durable.

Carbon steel material: economical, practical and high-strength, suitable for conveying low-corrosive biomass materials such as dry wood chips, straw, and rice husks. Its anti-rust ability can be significantly enhanced by spraying anti-corrosion paint or galvanizing, which is the most cost-effective conventional choice.

Stainless steel material: It has excellent corrosion resistance and hygienic standards, especially suitable for high-humidity materials, materials containing salt/corrosive components, and food-grade biomass. Its easy-to-clean and rust-free characteristics ensure long-term stable operation of the equipment.

Wear-resistant steel material: With ultra-high wear resistance, the service life can reach 3-5 times that of ordinary carbon steel, which is an ideal choice for high-wear materials and hard shells. It is usually made of wear-resistant layer surfacing on the edge of the blade or integral wear-resistant steel plate, which greatly reduces maintenance frequency and operating costs.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

The biomass shaftless screw conveyor is mainly composed of spiral blades without a central shaft, U-shaped or tubular troughs, drive devices and auxiliary components. The spiral blade adopts an integrated molding process, and the shaftless design avoids winding. The material can be stainless steel or wear-resistant carbon steel, and the surface can be welded with a wear-resistant layer; the trough is a closed structure, lined with polyethylene or cast stone wear-resistant lining to reduce friction loss; the drive device includes a motor, a reducer and a coupling to provide stable power; the auxiliary components include the feed port, the discharge port, the sealing device and the frequency conversion control system. Some models are equipped with anti-blocking sensors. The overall structure is compact, and the various components work together to achieve continuous transportation of biomass materials.

The biomass shaftless screw conveyor rotates in a closed trough or tubular channel through a spiral blade without a central shaft, and uses the blade thrust to continuously push the biomass material. The shaftless design avoids the entanglement of fiber materials such as straw and vines. The large pitch blade is suitable for fluffy or sticky materials. The close fit between the spiral and the trough enhances the pushing force. It can handle various forms of biomass such as straw, wood chips, and energy crops.

Biomass shaftless screw conveyors are used in agricultural waste treatment, forestry processing, energy crop processing and organic solid waste treatment.

Biomass energy field: In biomass power plants, it is used to transport power generation raw materials such as straw and wood chips, as well as transport biomass ash after combustion; in biomass biogas projects, it is responsible for transporting fermentation raw materials and biogas residues and liquids to ensure the continuity of biogas production.

Garbage treatment field: Urban domestic waste contains a large amount of biomass components. Shaftless screw conveyors can be used to transport sorted biomass waste, such as kitchen waste and waste paper, to subsequent processing links to improve waste treatment efficiency.

Industrial production field: In food processing, papermaking and other industries, it is used to transport biomass waste, such as fruit residues in food factories and waste pulp in paper mills, to achieve waste recycling and reuse.

The biomass treatment scenarios are complex and diverse. From farmland straw collection to waste incineration power generation, the material characteristics and transportation requirements vary significantly. The biomass shaftless screw conveyor achieves "one machine for multiple uses" through modular design.

Free combination of length: the conveying length of a single machine can reach 30 meters, and it supports multi-stage series connection to meet the cross-regional operation needs of large-scale garbage treatment plants.

Flexible discharging method: It supports three modes of bottom discharging, end discharging and side discharging, and can be seamlessly connected with crushers, filter presses, boilers and other equipment.

Wide temperature adaptability: Equipped with a special high-temperature resistant lining, it can operate stably under a high temperature environment of 200°C, and is suitable for high-temperature working conditions such as biomass pyrolysis and incineration.

Choose a shaftless screw conveyor for transporting biomass, because the design without a central shaft prevents straw and vine entanglement, is suitable for fluffy/sticky materials, and can effectively cope with the transportation of multi-form biomass such as agricultural and forestry waste.

The choice of a shaftless screw conveyor for transporting biomass is mainly based on its strong anti-entanglement, high conveying efficiency and strong adaptability. These advantages accurately solve the key pain points in the transportation of biomass materials.

Strong anti-entanglement: Biomass materials, such as straw, wood chips, and organic waste, have long fibers, are easy to entangle, and have strong adhesion. Traditional shafted screw conveyors often have the center shaft entangled by the materials, causing blockage, wear, and even shutdown problems. The shaftless screw conveyor eliminates the center shaft design and directly pushes the materials with the integral steel spiral blades, completely eliminating the risk of entanglement.

High conveying efficiency: The biomass processing scene has an urgent need for continuous and large-scale transportation. The shaftless screw conveyor achieves efficient operation through structural optimization. Under the same diameter, its conveying volume is 1.5 times that of traditional models, and the maximum conveying capacity of a single machine is 300 tons/hour.

Superior performance: Biomass material transportation is prone to dust, odor, and spontaneous combustion risks. The shaftless screw conveyor adopts a U-shaped fully enclosed trough and a rainproof cover design to form a triple protection: the silicone sealing strip between the trough and the cover is fastened with bolts to ensure that the dust leakage rate is less than 0.01%, meeting food grade standards.

Strong adaptability: Biomass processing scenarios are complex and diverse, and the shaftless screw conveyor achieves "one machine for multiple uses" through modular design: equipped with a special high-temperature resistant liner, it can operate stably in a high-temperature environment of 200℃, suitable for pyrolysis, incineration and other working conditions.

Choosing us as a supplier, you will get a customized biomass shaftless screw conveyor solution - from agricultural waste to organic solid waste, all kinds of materials are adaptable, 304/316L stainless steel and other materials are optional, and support personalized configuration of blade wear layer and liner. We have more than 10 years of industry experience, providing full-process services from design, production to installation and commissioning, and the equipment is ISO certified. There are also 300+ successful cases endorsed, and we can provide on-site inspection opportunities in the same industry to ensure that the equipment is adapted to your working conditions.

The price of biomass shaftless screw conveyor starts as low as $2,100, and the price will fluctuate due to various factors. In terms of materials, if basic carbon steel is used, the price is affordable; but for conveying corrosive biomass, such as kitchen waste, 304/316L stainless steel is required, and the cost will increase accordingly. In terms of specifications, the larger the pipe diameter and the size of the tank, the higher the conveying volume, and the price will also rise accordingly; under the demand for long-distance conveying, the equipment structure is strengthened, and the price is also affected. Customized functions, such as adding special anti-winding design and high-precision frequency conversion speed regulation device, will also change the price. We support on-demand customization and will provide you with accurate quotations based on your material characteristics, conveying distance, working conditions, etc., while ensuring the adaptability and quality of the equipment, taking into account cost-effectiveness.

In today's booming biomass energy, solid waste treatment and environmental protection industries, the efficiency and reliability of material conveying have become key factors restricting the development of the industry. Biomass shaftless screw conveyor, with its unique design concept and excellent performance, is gradually becoming the first choice for handling complex materials such as straw, wood chips, and organic waste.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!