Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Sludge shaftless screw conveyor completely eliminates the interference between the center shaft and the sludge winding, and can maintain continuous and stable operation even when conveying high-viscosity sludge with a water content of more than 60%, fiber-containing papermaking waste or domestic garbage.

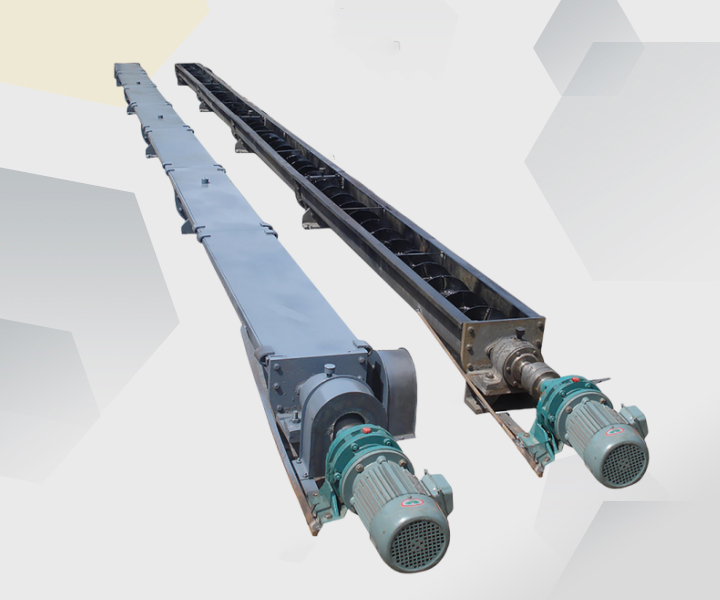

Type: single shaftless/double shaftless

Diameter: 150 - 470 mm

Installation angle: 0-15° or 0-30°

Length: 0-20 m or 0-30 m

Output: 0.8 tons/hour - 45 tons/hour

Power: 0.55 kW - 5.5 kW Speed: 29 rpm

Structural material: carbon steel, hot-dip galvanizing, 304/316 stainless steel, hardened alloy, etc.

Angle: <40 degrees

Application: It can be used to handle viscous, high-water content, wet sludge, such as municipal solid waste, dehydrated, concentrated or conditioned sludge, kitchen waste, domestic garbage, and waste from meat/fish/fruit and vegetable processing.

Sludge shaftless screw conveyor is a conveying equipment designed for high-viscosity, fiber-containing impurities sludge. It adopts a center-shaftless structure to completely solve the problem of easy clogging and difficult maintenance of traditional screw conveyors. It can realize high-speed, efficient, closed and low-consumption conveying of materials such as sludge, screen residue, floating slag, and kitchen waste. In addition, we can also customize a suitable shaftless screw conveyor for you according to your conveying length, conveying volume, and conveying site.

The inclination design of the sludge shaftless screw conveyor directly affects the conveying efficiency, power consumption and equipment stability. It needs to be accurately set in combination with the sludge characteristics, conveying distance and working conditions.

The inclination range is related to efficiency: the recommended conventional inclination is ≤20°, which can maintain a rated efficiency of more than 85%. For example, if the municipal dewatered sludge with a moisture content of 75% is conveyed at 15°, the energy consumption per meter will only increase by 12% compared with horizontal conveying. The maximum inclination does not exceed 40°.

The core influencing factors of the inclination design: the inclination of high-water content sludge is ≤18°, and the inclination of low-water content dried sludge can be up to 45°; the inclination of sticky sludge is ≤15°, and polyethylene lining is used to reduce retention, and the inclination of inorganic sludge is relaxed to 25°.

Optimization scheme of inclination design: when the inclination is greater than 20°, you can choose a cast stone plate with upgraded inner lining of the tank; for large inclinations of ≥25°, you can add 0.5mm wear-resistant ribs or install anti-slip convex strips every 3 meters to prevent sludge backflow during shutdown.

The sludge shaftless screw conveyor has outstanding performance in the transportation of complex materials such as sludge due to its unique design and performance advantages.

Strong anti-winding and clogging ability: the design without a central shaft fundamentally avoids the clogging problem caused by fiber and ribbon sludge winding around the shaft of traditional shafted equipment.

High conveying efficiency and wide adaptability: The spiral blades fit tightly with the trough body, with strong pushing force, and can handle high-water content, viscous or semi-solid sludge; the variable pitch design can adapt to different material characteristics.

Excellent sealing performance: The fully enclosed trough body or tubular structure effectively prevents sludge leakage, odor diffusion, and avoids secondary pollution, which is especially suitable for municipal sewage treatment and other scenes with high environmental requirements.

Durable material and easy maintenance: Made of 304 stainless steel or wear-resistant carbon steel, the spiral blades can be welded with a wear-resistant layer to extend the service life.

Low energy consumption and stable operation: The shaftless design reduces the friction resistance between the material and the equipment, the motor load is small, and the energy consumption is reduced by 20%-30% compared with traditional equipment; it runs smoothly and has low noise.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

The shaftless sludge screw conveyor adopts a spiral blade without a central shaft design. The motor drives the rotation to generate axial thrust, pushing the sludge forward along the U-shaped or tubular trough. During operation, variable pitch or variable speed adjustment is used to achieve uniform feeding, while low-speed operation reduces energy consumption and wear. The overall structure is compact and can be installed horizontally or tilted to achieve efficient and continuous transportation of sludge.

Supports multiple installation methods such as horizontal, tilted, and vertical. The conveying length, angle, and speed can be flexibly adjusted according to the on-site working conditions, providing customized solutions for various sewage treatment scenarios.

Diverse drive devices: The drive device can select cycloidal pinwheel reducer, hard tooth surface gear reducer, etc. according to actual needs. The cycloidal pinwheel reducer has a compact structure and is suitable for light-load and low-speed conveying scenarios; the hard tooth surface gear reducer has a strong load-bearing capacity and performs well under heavy-load and high-speed conditions.

A variety of inlet and outlet forms: The inlet and outlet are available in a variety of forms such as square and circular, which can be customized according to the on-site process layout and docking equipment to ensure smooth material in and out.

Multi-stage series and mobile design: For ultra-long-distance sludge conveying tasks, multi-stage series installation can be used to achieve ultra-long-distance material conveying. In addition, the design of the mobile shaftless screw conveyor enables it to operate flexibly in different work locations.

Among the sludge shaftless screw conveyors, single-axis and double-axis are two typical types based on structural differences, and the applicable scenarios and performance characteristics are significantly different.

Single-axis shaftless screw conveyor: There is only one spiral blade without a central shaft, which fits tightly with the closed tank body and pushes the material through the rotation of the blade. It has a simple structure and low cost, and has high efficiency in conveying small and medium-sized sludge flows of ≤50 cubic meters per hour, especially suitable for sludge containing fiber and block impurities.

Double-axis shaftless screw conveyor: It consists of two parallel, opposite-rotating shaftless spiral blades, which push materials through meshing linkage. The trough is U-shaped or tubular, and has stronger sealing. Its conveying force is 1.5-2 times that of the single-axis model, and can handle sludge with high viscosity and moisture content > 85%.

Sludge shaftless screw conveyor can be used in different industries. The following is the feedback from our customers.

Sludge conveying in municipal sewage treatment plants: The original shaft screw conveyor has high maintenance costs and low sludge dewatering efficiency due to frequent blockage. After replacing it with the WLS-320 shaftless screw conveyor, the equipment runs stably, completely solves the problem of winding and blockage, and improves the conveying efficiency by 30%.

High-fiber sludge conveying in paper mills: Because the sludge contains a large amount of fiber impurities, traditional screw conveyors frequently get stuck, affecting production continuity. After adopting the WLS-400 anti-winding shaftless screw conveyor equipped with a wear-resistant liner, the equipment has been running continuously for 6 months without any faults, and the sludge conveying is smooth.

Corrosion-resistant conveying of chemical sludge: facing the problem that chemical sludge is highly corrosive and traditional equipment is prone to rust and leakage. After selecting the 304 stainless steel shaftless screw conveyor, the equipment has excellent corrosion resistance, no leakage risk, and fully meets environmental protection requirements.

As an equipment manufacturer for more than ten years, we customize conveying equipment of different types and solutions for customers, focusing on providing reliable sludge conveying solutions for municipal, papermaking, chemical and other industries. Made of special alloy steel or stainless steel, equipped with anti-winding spiral blades and wear-resistant liner design, it effectively solves the industry pain points such as easy blockage, corrosion, and leakage of traditional equipment, supports multiple installation methods, and has won wide recognition from customers with stable equipment performance and high-quality after-sales service.

The sludge shaftless screw conveyor has redefined the conveying standards for high-viscosity and easy-winding materials with its innovative center-shaft-free design. From municipal sewage treatment to industrial hazardous waste disposal, its environmental protection, high efficiency and durability are driving the industry's transformation towards green and low-carbon.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!