Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Compound Fertilizer Screw Conveyor is a core piece of equipment in the compound fertilizer production process for continuous material transfer. Driven by a motor, the screw shaft rotates, causing blades to push materials for transport. Its flexible adaptability makes it a crucial link between seed processing and fertilizer production. The equipment offers a wide range of types, flexibly adopting horizontal, inclined, or vertical conveying angles to meet the needs of different conveying scenarios. Horizontal single units can reach a maximum length of 30 meters, meeting long-distance material transfer requirements; vertical and inclined conveying systems can accommodate connections between equipment with different height differences, achieving a three-dimensional layout of the production process.

The Compound Fertilizer Screw Conveyor has a maximum pipe diameter of 800mm, which can be precisely matched to conveying volume requirements. It offers two material options: carbon steel and stainless steel. Carbon steel is suitable for conventional working conditions, while stainless steel meets the requirements of corrosion resistance and high hygiene standards in operating environments. Comprehensive non-standard customization services are also supported, allowing adjustments to blade type, inlet/outlet positions, and control methods based on production line layout and material characteristics. This comprehensively meets the diverse needs of compound fertilizer from raw material transport to finished product transfer, providing a reliable guarantee for improved production efficiency.

Based on customer production needs and site conditions, our Compound Fertilizer Screw Conveyors are mainly divided into three types: horizontal, inclined, and flexible hose. Each type has its own structural features and advantages.

Horizontal Screw Conveyor: Utilizes a horizontally arranged cylindrical casing and helical blades. It has a simple and compact structure, provides stable conveying, and is suitable for short-distance conveying within a single plane. A single unit can reach a maximum length of 30 meters.

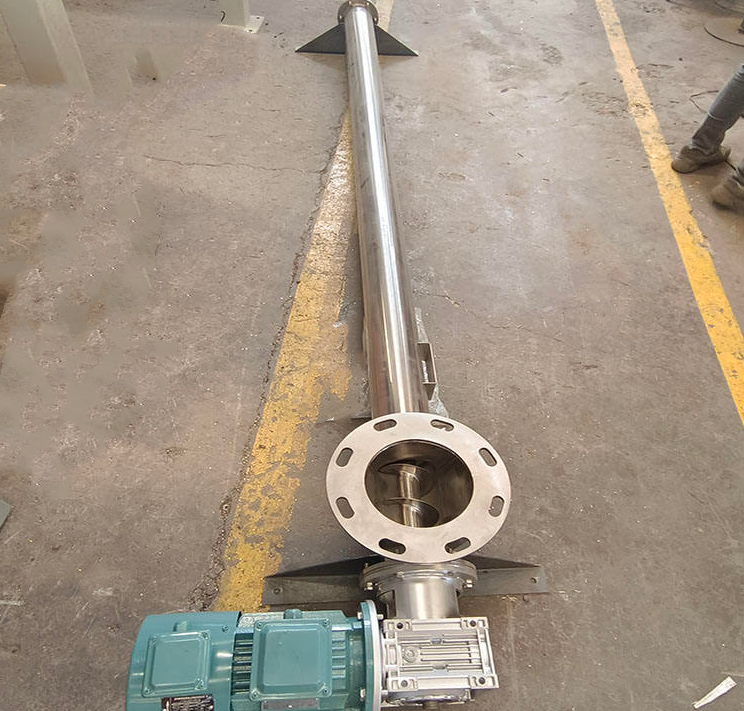

Inclined Screw Conveyor: The casing is designed at a certain angle. By adjusting the blade pitch and speed, the conveying height can be increased. It can achieve vertical material conveying between different floors or equipment, and is often used for connecting compound fertilizer storage piles and processing equipment.

Flexible Hose Screw Conveyor: Employs a flexible hose and an internal helix, offering high flexibility. The conveying path can be easily bent and adjusted, adapting to complex sites or mobile conveying needs.

The Compound Fertilizer Screw Conveyor, with its wear-resistant structure, flexible customization, and sealed dustproof design, enables continuous and stable material conveying, helping companies improve production efficiency and reduce losses, making it the preferred equipment in the fertilizer industry.

Compact Structure: With no complex traction components and small lateral dimensions, it is particularly suitable for space-constrained compound fertilizer production line layouts.

Multi-directional Conveying: Supports horizontal, vertical, and inclined conveying, and can operate in reverse or convey materials in two directions simultaneously.

Precise Control: By adjusting the screw speed, the conveying volume can be precisely controlled with an error rate of less than 5%, meeting the strict proportioning requirements of trace components in compound fertilizer formulations.

Adaptable to Complex Materials: Can convey powdery, granular, and small lump materials, and for sticky materials, a shaftless screw design can be used to reduce the risk of adhesion and clogging.

Fully Sealed Conveying: Utilizing a sealed structure, it effectively prevents compound fertilizer dust leakage, improving workshop air quality.

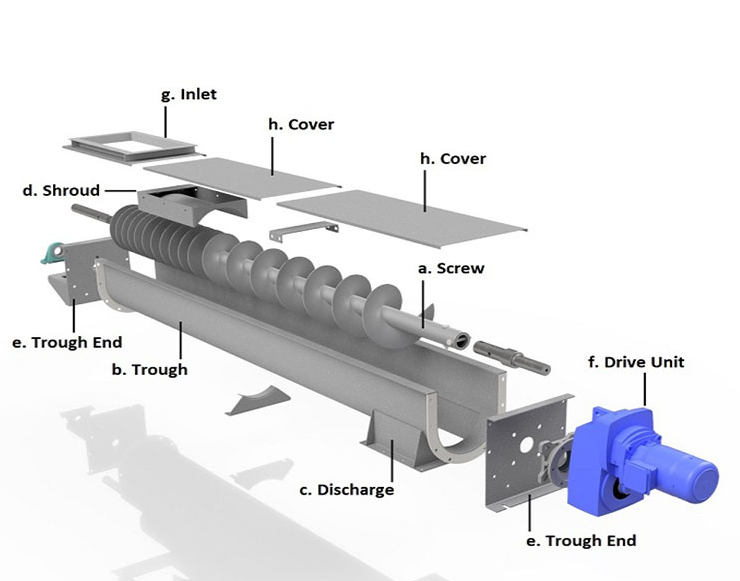

The Compound Fertilizer Screw Conveyor consists of a screw shaft, screw blades, a trough, a drive unit, and inlet/outlet ports. It achieves stable material transport through screw rotation, featuring a compact structure and support for non-standard customization to meet diverse production needs.

Screw Shaft: The screw shaft is made of extra-thick seamless hollow steel tubing, combining high strength and lightweight advantages, and facilitating easy assembly. The shaft diameter typically ranges from 50-100mm, and is connected segment by segment using high-strength bolts to meet long-distance conveying requirements.

Screw Blades: Different types of blades are available depending on the characteristics of the compound fertilizer and related materials. Solid screw surfaces offer a simple construction and strong conveying capacity, suitable for dry granular or powdery materials; paddle-type screw surfaces also provide a mixing function, specifically designed for materials with high viscosity or compressibility, ensuring smooth conveying.

Trough: Primarily available in U-shaped and circular shapes. U-shaped troughs are suitable for horizontal conveying and have a simple structure; circular troughs are often used in sealed equipment feeding scenarios. The material is 3-6mm thick steel plate, with a standard section length of 1-3 meters. Sections are assembled by bolting.

Feed Inlet: Equipped with an adjustable gate on the trough cover, it precisely controls the material entry speed to adapt to different conveying rhythms. A multi-point feeding design can be customized to flexibly meet the material supply needs of different stages in compound fertilizer production.

Discharge Outlet: Located at the bottom of the trough, it is also equipped with a gate to regulate the material discharge. Some models support multi-point unloading mode, facilitating connection with subsequent processing equipment such as mixers and packaging machines.

The Compound Fertilizer Screw Conveyor uses a rotating screw shaft to convey materials. A motor drives the screw shaft to rotate, and the screw blades fixed to the shaft rotate accordingly, pushing the material along the axial direction of the trough. After falling into the trough from the top feed inlet, the material is driven by the continuous rotational force of the screw blades, forming a stable push flow, and finally discharged from the bottom discharge outlet. The equipment precisely regulates the conveying volume and speed by controlling the screw shaft speed and gate opening. Simultaneously, the gap design between the trough and the blades ensures conveying efficiency and reduces resistance, making it suitable for the continuous and stable conveying of compound fertilizer raw materials, powders, and granular materials.

| Specifications | Spiral diameter (mm) | Pitch(mm) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) |

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3.0 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Medium | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62.0 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

| Material size | Material abrasiveness | Recharge Factor | K | A | |||||||

| Powder | Non-abrasive Semi-abrasive | 0.35-0.4 | 0.0415 | 75 | |||||||

| Powder | Grindability | 0.25-0.3 | 0.0565 | 35 | |||||||

| Small pieces a<60mm | Non-abrasive Semi-abrasive | 0.25-0.3 | 0.0537 | 45 | |||||||

| Small pieces a<60mm | Non-abrasive Semi-abrasive | 0.2-0.25 | 0.0645 | 25 | |||||||

As a professional conveying equipment manufacturer, we conduct in-depth analysis of the raw material characteristics, production capacity requirements, and site conditions of compound fertilizer enterprises of different sizes and processes, and tailor high-speed and stable Compound Fertilizer Screw Conveyor solutions.

Compound Fertilizer Production Line: The problem of continuous material supply between the raw material silo and the mixer/granulator needs to be solved. A horizontal + inclined combined screw conveyor is selected. The horizontal model handles the short-distance transfer from the raw material silo to the mixer, while the inclined model connects the mixer and the granulator, realizing material conveying between equipment on different floors.

Organic Fertilizer Processing Plant Conveying Sticky Materials: Facing the dilemma of adhesion and blockage when conveying raw materials containing moisture. Custom-designed paddle-type helical blades on the screw conveyor combine conveying and mixing functions, effectively solving the problem of caking in viscous materials. With a U-shaped chute and a reasonable 10mm clearance design, the equipment is adaptable to conveying needs from the fermentation workshop to the screening machine, with a single unit processing capacity of 15m³/h.

Quantitative addition of compound fertilizer anti-caking agent: Precise conveying and mixing of the anti-caking agent is required before finished product packaging. The screw conveyor, with a hollow shaft design and pre-embedded heating wires to ensure material heating and mixing, combined with an electromagnetic speed control system, can precisely control the amount of anti-caking agent conveyed at a standard of 3.5 kg per ton of fertilizer. The equipment seamlessly integrates with the packaging machine, and the discharge port supports 360° rotation and repositioning to adapt to the production line layout.

As a material transfer link in compound fertilizer production, the Compound Fertilizer Screw Conveyor can be deeply integrated with mixers, screening machines, and packaging machines to build an efficient and continuous production process.

Screw Conveyor + Mixer: The screw conveyor receives nitrogen, phosphorus, and potassium base raw materials and additives from the raw material silo, precisely feeding the materials into the mixer according to a preset ratio through a quantitative conveying function. Horizontal models are suitable for short-distance feeding within the same floor, while inclined models can connect silos at different heights to the mixer.

Screw Conveyor + Screening Machine: After the screening machine completes the grading and impurity removal of compound fertilizer granules, the screw conveyor can directly connect to its discharge port, quickly transferring qualified granules to the next process. For granules of different sizes after screening, multiple conveyors can be configured for separate transfer, or a multi-point unloading model can be used for classified conveying.

Screw Conveyor + Packaging Machine: In the finished compound fertilizer packaging stage, the screw conveyor receives finished granules from the storage silo, controlling the conveying volume through frequency conversion speed regulation to feed materials uniformly to the packaging machine. The equipment can be linked with the packaging machine's weighing system to achieve integrated conveying-weighing-packaging operations. The discharge port supports 360° rotation and position adjustment, accurately connecting to the inlets of different packaging machine models.

The length of a Compound Fertilizer Screw Conveyor needs to be flexibly selected based on the installation method. Our horizontal screw conveyors for compound fertilizer can reach a maximum length of 30 meters. Ultra-long-distance conveying can be achieved by connecting multiple units in series, supported by a central bearing, balancing long-distance conveying with operational stability, suitable for long-distance material transfer in production lines. Inclined models, affected by material gravity and backflow, are limited to a length of 8 meters, requiring a suitable inclination angle to ensure efficiency. Vertical models, relying on a strong thrust blade design, can be 6 meters long to meet the connection needs of equipment on different floors.

Dahan Machinery's Compound Fertilizer Screw Conveyor starts at a factory direct price of $500, with prices flexibly adjusted according to configuration differences, offering excellent value for money. The basic model is a standard carbon steel horizontal model, suitable for short-distance conveying of conventional granular compound fertilizer, meeting the basic needs of small planting bases and small-batch processing.Prices are primarily influenced by materials, specifications, and functions: Stainless steel construction or extended conveyor lengths will increase the price; inclined/vertical models, equipment with variable frequency speed control, and multi-point unloading functions will be more expensive due to higher technical requirements. Non-standard customization services are supported, such as special blade designs and corrosion-resistant/high-temperature treatments. Prices will be calculated based on the complexity of the solution.

DaHan Machinery supports a full range of non-standard customization services. For different process requirements, the inlet and outlet positions can be flexibly adjusted, such as side inlet/bottom outlet, multi-port inlet/outlet, square/round/irregular shapes, and angles. We also provide integrated modification solutions for vibrating screens, mixers, and other equipment to achieve seamless integration of the conveyor system with the entire production line. The product uses high-wear-resistant alloy spiral blades and a thickened trough design, suitable for various working conditions such as granules, powders, and viscous materials. It has successfully served many large fertilizer companies in China, providing one-stop service from solution design to commissioning.

With its high speed, stability, and flexible adaptability, the Compound Fertilizer Screw Conveyor has become an indispensable core piece of equipment in compound fertilizer production. Its non-standard customization capabilities can precisely match different process requirements, optimize inlet and outlet structures, and help enterprises improve production efficiency and reduce operation and maintenance costs. It is a reliable choice for promoting the intelligent and refined development of the fertilizer industry.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!