Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Shaftless Screw Conveyor for Livestock Farm Sludge is a conveying equipment used for transferring sludge from livestock farms. Its core function is to transfer sludge formed from livestock manure and wastewater sedimentation to different treatment stages, connecting the entire process of sludge collection, dewatering, storage, and harmless treatment, completely solving the pain points of traditional sludge conveying, such as clogging, entanglement, and odor diffusion. A single unit can achieve continuous conveying up to 30 meters, eliminating the need for multiple units to meet medium-to-long distance transfer needs. It also supports multiple units in series, flexibly extending the conveying length to adapt to large-scale sludge centralized transfer scenarios in large livestock farms and breeding parks.

Materials and structure can be customized as needed. The conveying angle, model specifications, and materials can be customized according to the actual production needs of the farm, site layout, and sludge moisture content, matching the transfer needs of different scenarios and providing livestock farms with personalized and efficient sludge transfer solutions.

The Shaftless Screw Conveyor for Livestock Farm Sludge features a shaftless structure to prevent clogging and entanglement, 30-meter single-unit conveying + multiple units in series, multiple material options, fully enclosed to prevent odor diffusion, and supports non-standard customization.

Anti-clogging: The shaftless design is its biggest highlight. The integrally formed spiral blades rotate in the U-shaped trough, completely eliminating the core area where materials can become entangled, allowing long-fiber impurities and hair to pass through easily.

Self-cleaning ability: The unique shaftless structure combined with the smooth, wear-resistant trough results in a small contact surface and low adhesion rate during sludge conveying. When the machine stops, the rotation of the spiral body effectively scrapes away residue from the bottom of the trough, providing strong self-cleaning capabilities. Corrosion Resistance: Key components can be made of high-strength wear-resistant steel or stainless steel, and surface treatment or special steel materials are used for corrosive environments, extending the service life of the equipment under harsh working conditions.

Fully Enclosed: Adopting a fully enclosed conveying system effectively locks in odors, prevents sewage leakage and dust dispersion, greatly improving the environment of the livestock farm and surrounding areas.

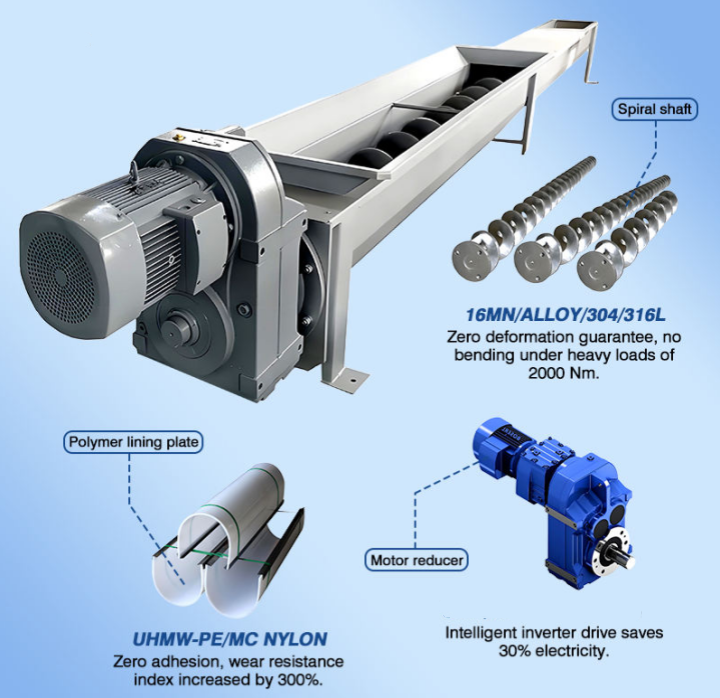

The Shaftless Screw Conveyor for Livestock Farm Sludge is centered around a shaftless screw blade and consists of a drive system, a sealed cylinder, and sealed inlet and outlet ports. The shaftless design eliminates material jamming and is suitable for viscous sludge.

Variable Frequency Motor: This is the heart and brain of the conveyor. It not only provides powerful driving force but also controls the conveying volume and speed by adjusting the motor speed.

Casing: The U-shaped trough casing of the conveyor forms a sealed channel for material transport. To cope with the high corrosiveness and high humidity environment of livestock sludge, the casing is available in a variety of materials, which not only reduces sludge adhesion and facilitates cleaning but also greatly enhances corrosion resistance and wear resistance.

Shaftless Screw Body: This is a spiral belt without a central shaft, made of high-strength wear-resistant steel or stainless steel, either integrally formed or segmented. Its unique continuous spiral surface creates a powerful and uniform thrust when rotating, effectively pushing high-viscosity sludge, and completely eliminating the risk of fiber impurities wrapping around the shaft due to the absence of a central shaft.

Customized Inlet and Outlet Ports: The inlet and outlet ports are the throat connecting the conveyor to upstream and downstream process equipment. They are usually custom-made according to the site interface dimensions and locations. To adapt to different working conditions, the inlet port can be designed as a rectangular open type, with a gate control or flange connection; the outlet port may be designed as a beveled type, square opening, or equipped with a discharge gate to achieve material discharge and process control.

Our factory produces Shaftless Screw Conveyors for Livestock Farm Sludge with three core material options: carbon steel, stainless steel, and PP polypropylene. Carbon steel offers high cost-effectiveness for general applications, stainless steel provides corrosion and wear resistance for high-intensity transfer, and PP polypropylene offers anti-sticking and acid/alkali resistance for special corrosive sludge scenarios.

Carbon steel: Made of high-quality carbon steel for the cylinder and blades, it boasts strong overall rigidity and excellent load-bearing capacity. With mature manufacturing processes and low equipment manufacturing costs, it is suitable for small and medium-sized livestock farms with weakly corrosive sludge and limited budgets, making it an economical and practical choice for large-scale transfer.

Stainless steel: This is the mainstream choice for livestock farm sludge conveying, often using 304 or 316 stainless steel. It possesses excellent corrosion and wear resistance, resisting corrosive media from manure and wastewater residues in livestock farm sludge. It is also non-stick and easy to clean, suitable for sludge conditions with high water content and high viscosity.

PP polypropylene: Relying on the excellent acid and alkali resistance and anti-sticking properties of PP material, it has strong chemical stability and can withstand acid and alkali impurities in the sludge. Its smooth surface prevents material buildup, making it suitable for livestock farms with special anti-corrosion requirements and facilitating equipment installation and daily cleaning.

The Shaftless Screw Conveyor for Livestock Farm Sludge works by using a continuously rotating shaftless screw to smoothly and forcibly propel high-viscosity, impurity-containing sludge within a sealed U-shaped trough. When the variable frequency motor drives the shaftless screw to rotate, its unique continuous spiral surface contacts the sludge, generating a powerful axial thrust. Due to the shaftless design, the sludge and any mixed impurities such as feathers and fibers are not entangled, but are smoothly moved forward along the smooth trough bottom by the spiral belt.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

A large-scale pig farm produces a large amount of sludge daily, requiring the transfer of sludge from the sludge pool to the dewatering workshop over a distance of 28 meters. The sludge has a water content of 45% and is highly viscous, making traditional equipment prone to clogging and odor leakage. A customized PP polypropylene shaftless screw conveyor for livestock farm sludge was designed for this farm. The single unit provides 28-meter conveying without splicing, and the anti-sticking material completely solves the problem of sludge accumulation. The fully enclosed structure prevents odor diffusion. The equipment supports variable frequency speed control, allowing for flexible adjustment based on the amount of sludge, and is suitable for the farm's 24-hour continuous operation needs.

The maximum inclination angle of the Shaftless Screw Conveyor for Livestock Farm Sludge can reach 40°. The specific conveying angle depends on the water content of the sludge. Regular use is typically between 15°-30°, and can be flexibly adjusted according to actual transfer needs. For the high water content and high viscosity characteristics of livestock farm sludge, the equipment has been specially optimized for large-angle design. The blades adopt a thickened wear-resistant design and are tightly fitted to the inner wall of the cylinder, effectively preventing sludge from sliding down and accumulating during inclined conveying. Combined with the fully enclosed cylinder structure, it ensures no leakage and no odor diffusion during large-angle conveying.

Compared with ordinary shafted conveyors, the Shaftless Screw Conveyor for Livestock Farm Sludge is comprehensively optimized for the characteristics of livestock farm sludge. Its core advantages are concentrated in three aspects: anti-clogging, anti-leakage, and strong adaptability. The shaftless structure completely eliminates the dead corners of contact between the shaft and the sludge, preventing viscous sludge from wrapping around the shaft and accumulating. The blades are tightly fitted to the inner wall of the cylinder, which can simultaneously scrape away the sludge adhering to the wall, adapting to the conveying of livestock farm sludge with different water content. Featuring a fully enclosed tubular design and sealed inlet and outlet ports, this system effectively prevents the spread of sludge odors and prevents sludge leakage from contaminating the farm environment.

Dahan Machinery is a direct supplier of Shaftless Screw Conveyors for Livestock Farm Sludge, with prices starting from $650. There are no middlemen markups, offering excellent value for money. The specific price needs to be calculated based on the actual needs of the livestock farm, primarily influenced by conveying capacity, conveying length, and application scenario. Different inclination angles and material configurations have corresponding pricing standards. Carbon steel, stainless steel, and PP polypropylene materials will have reasonable price adjustments due to differences in process and suitability. Our factory supports one-on-one non-standard customization. We will recommend a suitable model based on your site layout and sludge characteristics, and then provide a detailed quotation. The pricing is completely transparent with no hidden fees.

The Shaftless Screw Conveyor for Livestock Farm Sludge, with its outstanding advantages of being clog-free, easy to maintain, and enclosed, transforms the dirty, laborious, and difficult sludge treatment work into a high-speed, automatic, and clean modern process.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!