Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Screw Conveyor for Mud Cake is used to transfer sludge-like materials produced by dewatering equipment such as filter presses and centrifuges. The material is flexible, and carbon steel, high-manganese steel, or stainless steel can be selected according to the operating conditions. A single unit can convey materials up to 30 meters long. Multiple units can be connected in series via flanges or couplings to achieve ultra-long-distance or complex path conveying. It also supports variable frequency speed regulation and PLC intelligent control, precisely matching the upstream and downstream process rhythms, making it a high-speed and reliable solution for solid-liquid mixture conveying scenarios.

A Screw Conveyor for Mud Cake can be used in conjunction with multiple units, accurately conveying sludge cake to drying, incineration, landfill, or resource utilization processes. It is suitable for conveying lengths of 2-30 meters and conveying capacities of 2-30 tons/hour. The tank size and material can be customized according to different operating conditions, providing reliable assurance for the efficient operation of the entire sludge cake processing process.

Our factory, based on customer needs, categorizes Screw Conveyors for Mud Cake into three main types according to structural differences: shafted, shaftless, and dual-shaft. Each type is designed for different mud cake characteristics and working conditions, adapting to various production scenarios.

Shafted Mud Cake Screw Conveyor: Utilizes a traditional central shaft + helical blade structure. The shaft is made of heat-treated steel, and the blades are welded from wear-resistant manganese steel. Its advantages include strong conveying stability and suitability for medium to low viscosity mud cakes with a moisture content of 30%-50% and weak agglomeration.

Shaftless Mud Cake Screw Conveyor: Eliminates the central shaft, using shaftless helical blades for direct drive. The blades are made of a single piece of wear-resistant alloy material. Its core advantage is that the shaftless design completely solves the problem of mud cake entanglement. It is suitable for mud cakes with high moisture content, high viscosity, and a small amount of fibrous impurities, and is ideal for operations in confined spaces.

Dual-shaft Mud Cake Screw Conveyor: Consists of two parallel helical shafts rotating in opposite directions, with meshing blades, driven by synchronous gears. Through biaxial meshing extrusion, it can break up and loosen agglomerated mud cakes while enhancing conveying thrust. It is suitable for compacted mud cakes with a moisture content of 20%-40% and high hardness, or mud cakes containing lumpy impurities.

The Screw Conveyor for Mud Cake specifically addresses the pain points of mud cakes being highly viscous and prone to clumping. It employs an anti-stick coating tank and a variable pitch/shaftless/biaxial structure to completely eliminate material entanglement and blockage. The fully sealed design prevents odor and dust leakage, providing reliable protection for mud cake transfer in various industries.

Strong anti-sticking and anti-clogging capabilities: Through variable pitch blades, an anti-stick coating, and a shaftless/biaxial structure design, it can effectively handle mud cakes with different moisture contents, preventing material adhesion, entanglement, or blockage, ensuring continuous conveying.

Wide Adaptability: Supports horizontal and inclined conveying, with shafted, shaftless, and dual-shaft options available to meet the sludge cake processing needs of various industries such as municipal engineering, chemical engineering, and papermaking. It can be connected to filter presses, dryers, and other equipment for process linkage.

Easy Disassembly: Fully sealed or semi-open structure reduces odor and dust leakage. Removable parts facilitate cleaning and maintenance. Variable frequency speed control allows for flexible adjustment based on feed rate.

U-Shaped Sealed Tank: The U-shaped tank, with replaceable lining, prevents sludge corrosion and facilitates maintenance.

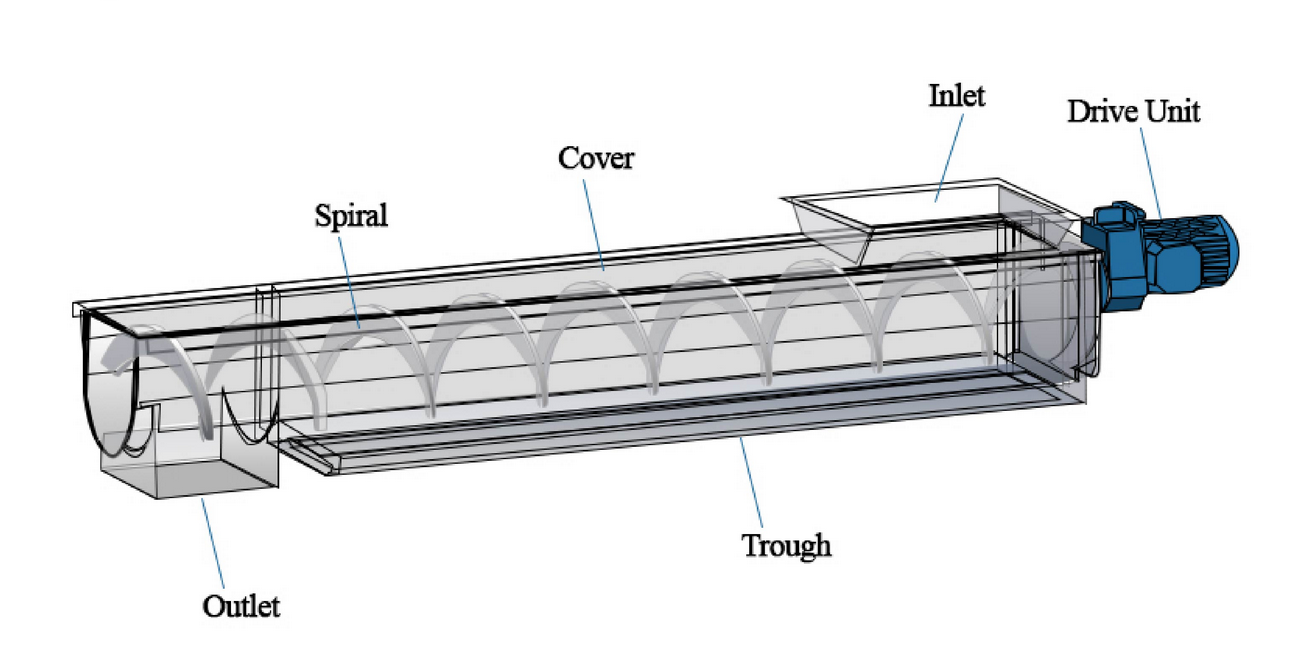

The Screw Conveyor for Mud Cake main body includes a non-stick coated U-shaped tank and shafted/shaftless/dual-shaft helical blades. The drive system includes a motor, reducer, and frequency converter, with precise coordination among components to adapt to different working conditions for sludge cake transfer.

Conveying Body: Composed of the U-shaped tank, helical blades, and helical shaft, it is the core for material carrying and conveying.

Drive System: Includes a motor, reducer, and coupling, providing stable power to the equipment. Some models are equipped with a variable frequency drive (VFD).

Sealing Device: Employs a combination of labyrinth seals and rubber sealing rings. The connection between the shaft end and the trough is reinforced to prevent leakage of mud cake odor and dust.

Feed/Discharge Components: The feed inlet is equipped with a buffer baffle to prevent impact. The discharge outlet can be equipped with a gate valve to control flow, adaptable to different connecting equipment.

The Screw Conveyor for Mud Cake uses a drive system to rotate the screw assembly, thus conveying materials. The motor, after being reduced in speed by the reducer, outputs torque to drive the screw blades to rotate within the U-shaped trough. The mud cake enters the trough through the feed inlet and, under the propulsive force of the screw blades and the friction of the trough, moves forward with the rotating blades, eventually exiting through the discharge outlet. Leakage is prevented throughout the process by the sealing device. The VFD allows for flexible adjustment of the conveying speed, ensuring continuous and stable mud cake transfer.

| Specifications | Spiral diameter (mm) | Pitch(mm) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) |

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3.0 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Medium | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62.0 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

| Material size | Material abrasiveness | Recharge Factor | K | A | |||||||

| Powder | Non-abrasive Semi-abrasive | 0.35-0.4 | 0.0415 | 75 | |||||||

| Powder | Grindability | 0.25-0.3 | 0.0565 | 35 | |||||||

| Small pieces a<60mm | Non-abrasive Semi-abrasive | 0.25-0.3 | 0.0537 | 45 | |||||||

| Small pieces a<60mm | Non-abrasive Semi-abrasive | 0.2-0.25 | 0.0645 | 25 | |||||||

As a specialized anti-clogging conveying device, Screw Conveyor for Mud Cake is widely applicable to sludge cake processing scenarios in various industries. Its flexible adaptability makes it a key piece of equipment for sludge cake conveying and process connection in various industries.

Municipal Wastewater Treatment: Connects to plate and frame filter presses and belt filter presses to convey dewatered municipal sludge cakes to sludge dryers, incinerators, or landfills, achieving sludge reduction treatment.

Chemical Sludge Cake Conveying: Used to convey acidic and alkaline sludge cakes and saline sludge cakes generated from chemical wastewater treatment. Because corrosion-resistant materials can be selected, it can adapt to highly corrosive working conditions.

Paper Industry: Transfers pulp sludge cakes after papermaking wastewater treatment, connecting to subsequent sludge cake crushing and resource utilization processes.

Dyeing and Textile Industry: Treats colored sludge cakes after dewatering dyeing and printing wastewater; the sealed structure prevents the diffusion of pigment dust.

The Screw Conveyor for Mud Cake is fully capable of inclined conveying. Its design, through optimized spiral structure and support devices, allows for inclined installation from 0° to 45°. During inclined conveying, the rotational friction of the shaftless spiral blades and the gravitational component of the material work together to drive the sludge cake upwards along the trough. Thickened, wear-resistant blades and a high-strength trough ensure stable operation under inclined conditions, preventing deformation or leakage. This function is widely used in sludge lifting in wastewater treatment plants and organic fertilizer conveying in agriculture.

The Screw Conveyor for Mud Cake can be directly connected to a filter press, and customized production is supported to adapt to on-site conditions. We will customize the shape, angle, and connection method of the conveyor inlet according to the type of filter press, outlet size, and height you are using, ensuring that the sludge cake smoothly enters the conveyor after being discharged from the filter press, avoiding leakage or accumulation. Simultaneously, the length, tilt angle, and installation method of the conveyor are adjusted according to the site space layout to achieve seamless integration with the filter press. The equipment can also be equipped with a material level sensor and a variable frequency speed control system to automatically adjust the conveying volume based on the filter press's discharge speed, ensuring the continuous and stable operation of the entire mud cake processing process.

The Screw Conveyor For Mud Cake has broad adaptability to mud cake moisture content. Its core components can stably convey various types of mud cake with moisture contents ranging from 20% to 60%, and its targeted structural design meets the needs of different humidity conditions. For low-moisture compacted mud cakes with a moisture content of 20%-40%, models with a twin-shaft meshing structure can achieve crushing, loosening, and conveying. For medium-moisture viscous mud cakes with a moisture content of 40%-50%, models with anti-stick coating troughs and variable pitch blades can prevent material adhesion and blockage. For high-moisture soft mud cakes with a moisture content of 50%-60%, shaftless screw conveyors, with their non-winding design, ensure smooth material propulsion. We support customized blade structure, materials, and drive parameters based on actual moisture content data, providing precise and suitable conveying solutions for municipal sludge, chemical waste, and papermaking mud cakes.

We are a manufacturer specializing in Screw Conveyors for Mud Cakes, capable of producing all types of models. We offer shafted, shaftless, and twin-shaft series products. Core components are made of wear-resistant manganese steel and 304 stainless steel, precision-processed to ensure durability. Supporting full-scenario customization, we can tailor the inlet structure, conveyor length, and tilt angle according to the sludge cake moisture content, site layout, and connecting equipment. Our products undergo rigorous quality testing and cover multiple industries including municipal wastewater, chemical, and papermaking, providing a one-stop service from selection consultation to after-sales spare parts.

With its core advantages of anti-clogging, wide adaptability, and strong customization, the Screw Conveyor for Mud Cake has become the preferred equipment for sludge cake transfer in various industries. Its diverse structure adapts to different moisture contents and operating conditions, seamlessly connecting to equipment such as filter presses. As the original manufacturer, we provide full-type customization and one-stop service, empowering the entire process from structural design to operation and maintenance, building a solid core support for the entire sludge treatment process.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!