Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Graphite Powder Inclined Screw Conveyor is a material conveyor specifically designed for the flammable, explosive, dust-generating, and highly fluid characteristics of graphite powder. Its primary function is to stably transfer graphite powder from one workstation to another, or to transport it to a designated silo, achieving automated and continuous operation. Addressing the dust-generating, adhesive, and conductive properties of graphite powder, the inclined screw conveyor typically employs a sealed structure and explosion-proof motor design to ensure the stability of the graphite powder during transport.

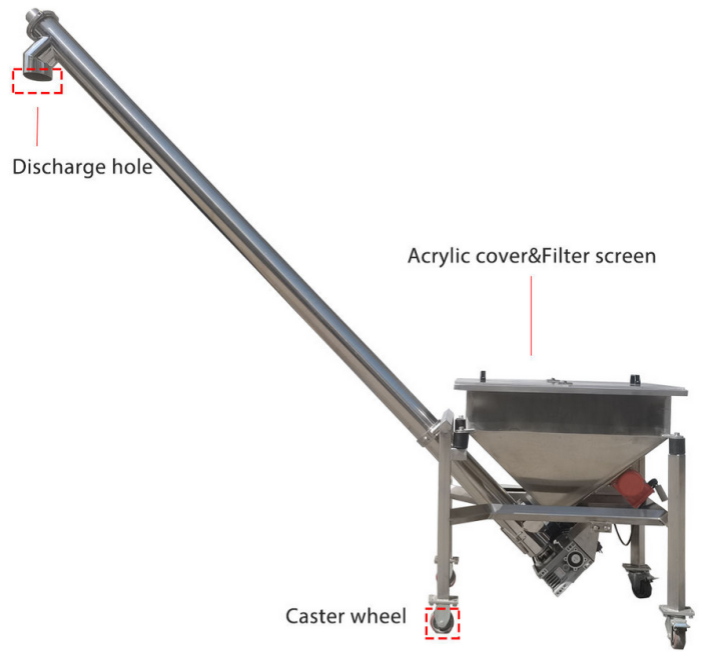

We support non-standard customization of the Graphite Powder Inclined Screw Conveyor. It can be specifically designed according to actual conveying distance, height, output, and installation space, and can be equipped with an explosion-proof motor to meet the safety requirements of flammable and explosive environments. A roller structure can also be added to improve the equipment's mobility and facilitate flexible use between different workstations. With its compact structure and stable operation, it is an ideal solution for graphite powder conveying and loading.

The Graphite Powder Inclined Screw Conveyor, designed to handle flammable, explosive, and dust-generating materials, is equipped with an explosion-proof motor. It supports non-standard customization and roller movement, easily achieving sealed, inclined transfer between hoppers.

Stable Conveying: The continuous rotation of the spiral blades propels the graphite powder, achieving continuous and uniform conveying, preventing fluctuations in material levels, and supporting 24-hour continuous operation, suitable for production lines requiring stable feeding.

Excellent Sealing: The enclosed structural design prevents graphite powder from flying during conveying, reducing dust pollution.

Space Saving: The inclined design allows for horizontal and lifting conveying within limited space, reducing auxiliary equipment and enabling more flexible layout.

Non-Standard Customization Support: Custom designs can be made according to conveying distance, height, output, and site conditions to meet different graphite powder conveying needs.

Explosion-Proof Motor: For graphite powder applications, an explosion-proof motor and anti-static design are available as options, improving the safety and reliability of equipment operation.

Our factory produces Graphite Powder Inclined Screw Conveyors in carbon steel, stainless steel, and PP materials. We can recommend the appropriate model and material based on your conveying requirements and operating conditions.

Carbon Steel: Carbon steel offers high structural strength and good load-bearing capacity, suitable for most conventional graphite powder conveying applications. It offers high cost-effectiveness, and after surface coating and rust-proofing treatment, it meets the needs of general industrial environments.

Stainless Steel: Stainless steel boasts excellent corrosion resistance and wear resistance. Its smooth inner wall prevents material adhesion, facilitating cleaning and making it ideal for applications requiring high cleanliness and corrosion resistance.

PP Material: PP polypropylene is lightweight, corrosion-resistant, and chemically resistant, suitable for conveying graphite powder in metal-sensitive or corrosive environments. Its smooth inner wall reduces material adhesion.

The Graphite Powder Inclined Screw Conveyor's structural design revolves around the core requirements of dust prevention, explosion protection, and adaptability to the flowability of powder materials. The overall structure is modular, with each component working together to complete the entire conveying process.

Sealed Housing: Utilizes a grooved/tubular sealing structure; the tilt angle can be customized. Sealed end caps at both ends of the housing seamlessly connect to the bearing housing.

Screw Blades: Most blades have a shaft design, allowing adjustment of blade spacing according to the flowability of graphite powder, ensuring smooth and unblocked conveying.

Explosion-proof Motor + Gearbox: Meets dust explosion safety standards, capable of handling the flammable and explosive working environment of graphite powder. The motor power is matched to the conveying volume and tilt angle, and the gearbox precisely adjusts the screw speed.

Inlet/Outlet: The inlet features a flange or funnel-type structure for seamless connection with upstream silos, mixers, and other equipment. An adjusting baffle at the outlet controls the discharge volume, preventing sudden spillage and accumulation of graphite powder.

The Graphite Powder Inclined Screw Conveyor operates on the principle of sealed powder conveying and explosion-proof safety design. Upon startup, the explosion-proof motor drives the gearbox, which in turn rotates the screw shaft, causing the screw blades on the shaft to rotate accordingly. When graphite powder enters the sealed housing from the inlet, it is propelled by the thrust of the blades, moving forward and upward along the inclined inner wall of the housing until it is precisely discharged from the outlet to the target hopper or workstation.

| Specifications | Spiral diameter(mm) | Pitch (mm) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | |

| small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3.0 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| medium | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62.0 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

A new energy graphite products factory previously relied on manual handling for graphite powder transfer, which resulted in severe dust pollution, low efficiency, and a risk of explosion. We customized a Graphite Powder Inclined Screw Conveyor for them. The equipment is equipped with an explosion-proof motor, adaptable to the 30° inclined conveying requirements of the workshop, and uses a sealed tubular casing to prevent dust leakage. It also features rollers for easy and flexible repositioning. After being put into use, it achieves automated transfer of graphite powder from the raw material silo to the processing station, increasing conveying efficiency by 4 times while ensuring dust concentration meets standards.

The tilt angle of the Graphite Powder Inclined Screw Conveyor can be designed according to the material characteristics and equipment structure. Generally, the conventional tilt angle is between 20° and 45°. Within a suitable range, it offers high conveying efficiency and stable operation, suitable for most continuous graphite powder conveying and feeding conditions. If a higher lifting height is required, the tilt angle can be increased to approximately 60° by increasing the screw diameter, optimizing the blade structure, or reducing the rotation speed. However, this requires appropriate matching of power and conveying capacity to avoid material backflow or a decrease in conveying volume.

Dahan Machinery's Graphite Powder Inclined Screw Conveyor is designed to address the dust-prone and easily adhered characteristics of graphite powder, with continuous optimization and upgrades in structural design, sealing methods, and material selection. We can provide customized solutions based on customers' conveying distance, tilt angle, throughput, and on-site installation conditions, supporting non-standard customized production. Optional features include explosion-proof motors, anti-static structures, and movable roller devices to meet safety and usage requirements under different working conditions. Prices start from $350, with specific configurations and prices subject to flexible adjustment based on actual needs.

Graphite powder inclined screw conveyors propel graphite powder through rotating helical blades at an inclined angle, achieving both inclined conveying and a certain height lifting. They are widely used in graphite processing, new materials, metallurgy, and chemical industries.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!