Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

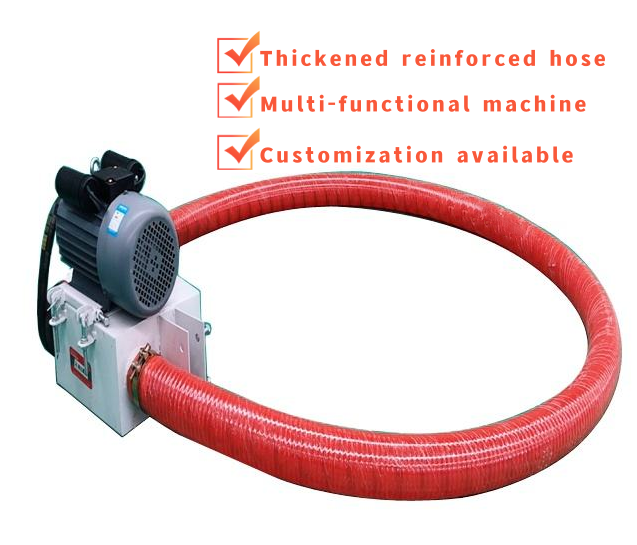

Flexible Screw Conveyor for Abrasive Sand is a customized conveying equipment for abrasive sand bulk materials, specifically designed to address the industry pain points of traditional conveying equipment, such as wear and tear, clogging, and dust leakage. The pipe diameter can be 100-160mm, and the output can reach 10-20 tons per hour. It supports multi-angle installation and 360° bending. The standard machine weighs approximately 75 kg and can be moved by a single person. We support non-standard customization and can add features such as roller supports and explosion-proof capabilities based on on-site conditions.

Our Flexible Screw Conveyor for Abrasive Sand is available in different types to meet various operating scenarios: diesel-powered, electric, handheld, and vehicle-mounted. All models support multi-angle installation, allowing you to choose the appropriate model based on your conveying needs.

Diesel-powered: Powerful, no external power supply required, suitable for outdoor work scenarios without electricity coverage, strong endurance, and capable of handling high-intensity continuous operation.

Electric: Low operating noise, suitable for fixed workstations in workshops for abrasive sand conveying, supports speed control for adjusting conveying volume, and uses 220V household electricity.

Handheld: Compact size and flexible operation, can be moved and operated manually, suitable for small-batch abrasive sand point feeding and material bagging in small-scale applications.

Vehicle-mounted: Can be directly mounted on trucks or engineering vehicles, highly mobile, can move with the work site, meeting the needs of short-distance transfer and multi-site deployment of abrasive sand.

The Flexible Screw Conveyor for Abrasive Sand features a flexible hose that can be bent to adapt to complex layouts, wear-resistant blades for durability, and sealed conveying to prevent dust leakage; it supports long-distance conveying and offers high cost-effectiveness to meet diverse working conditions.

Strong adaptability: The flexible hose can be bent flexibly to adapt to various complex workshop layouts and is compatible with the conveying of abrasive sand and sand powder of different particle sizes. Large-Diameter Inlet and Outlet: The inlet and outlet ports can be made with a 160mm diameter, significantly improving the feeding efficiency of abrasive sand and preventing material accumulation and blockage; coupled with an impact-resistant sealing kit, it can completely eliminate abrasive sand particle leakage and dust dispersion.

Wear-Resistant and Durable: The pipeline is made of high-strength rubber material, and the spiral blades and flexible conveying pipe can withstand the continuous scouring of sharp abrasive sand particles, significantly extending the service life compared to ordinary conveying equipment.

Simple and Easy to Operate: The handheld model can be operated by one person, saving labor and greatly reducing the transfer time of abrasive sand, improving work efficiency.

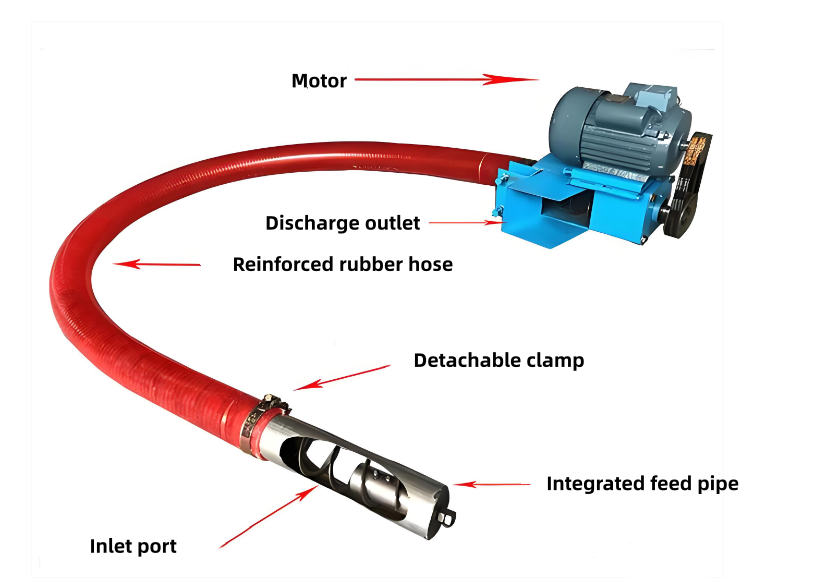

The Flexible Screw Conveyor for Abrasive Sand consists of a drive device, flexible conveying pipe, spiral blades, inlet and outlet ports, and a support frame. The overall structure is compact, occupies a small area, and can flexibly move through narrow spaces in the workshop, especially suitable for the dense equipment layout of abrasive sand processing workshops.

Drive System: As the power core, it is equipped with a reducer and coupling to accurately adjust the screw speed to control the conveying volume.

Flexible Conveying Pipe: Made of high-strength rubber hose, it can flexibly deform according to the installation angle, is wear-resistant and durable, and can be used in harsh environments.

Spiral Blades: Made of high-chromium alloy or wear-resistant ceramic coating material, the shaftless spiral blades can withstand the continuous scouring of sharp abrasive sand particles, extending the service life.

Inlet and Outlet Ports: The large-diameter design of the inlet port is adapted to the size of abrasive sand particles, significantly improving feeding efficiency and preventing material accumulation and blockage; the outlet port can be fine-tuned according to the specifications of the downstream equipment interface.

The core of the Flexible Screw Conveyor for Abrasive Sand achieves material transfer through the coordinated action of power drive, spiral propulsion, and sealed conveying. The diesel model is powered by a diesel engine, and the electric model is powered by a variable frequency motor. After the speed is adjusted by the reducer and coupling, it drives the wear-resistant spiral blades to rotate inside the flexible conveying pipe. The material enters through a large-diameter inlet and is propelled along the pipe by rotating blades. It is then conveyed at different angles through an adjustable-angle conveying pipe, and finally discharged from the outlet that connects to the downstream equipment.

| Model No. |

Length (Meters) |

Pipe diameter |

Loading Capacity (t/h) |

Motor phase-power (kw) |

Installation | Structure | Conveying height |

| RLS100 | 4 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 100mm | 5—8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS120 | 4 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 6 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| 8 meter | 120mm | 10—15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside | ||

| (Customized) | |||||||

| RLS-160 | 4 meter | 160mm | 10—15 | Three phase-5KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| 5 meter | |||||||

| 6 meter | |||||||

| 8 meter | |||||||

| (Customized) | |||||||

As the original manufacturer of Flexible Screw Conveyors for Abrasive Sand, we always focus on in-depth non-standard customization, providing one-on-one technical solutions for our customers, successfully achieving high-speed, wear-resistant, and sealed conveying of various abrasive sands.

Small Quartz Sand Processing Plant: Mainly engaged in the processing of refined quartz sand. Previously, the process of conveying screened quartz sand to the finished product warehouse relied on manual labor. We customized one Φ159 type abrasive sand flexible screw conveyor with a conveying length of 8 meters and a lifting height of 4 meters, directly connecting the screening machine outlet and the finished product warehouse inlet; achieving automated continuous conveying without manual intervention.

Large Sandblasting Treatment Plant: Undertakes sandblasting and rust removal services for bridges and ship components. Previously, fixed pipe conveyors were used, but due to the dense equipment and numerous columns in the workshop, the pipe layout was limited, resulting in multiple conveying dead ends. We provided four customized abrasive sand flexible screw conveyors, using flexible wear-resistant rubber hoses that can flexibly avoid obstacles in the workshop; the conveying path is optimized according to the workshop layout, perfectly adapting to complex layouts with no conveying dead ends.

National Abrasive Products Enterprise: Produces grinding wheels, sandpaper, and other products, requiring the conveying of various abrasives such as silicon carbide sand and corundum sand. Different types of abrasives need to be strictly separated to avoid cross-contamination. Using multiple fixed conveyors for different abrasives resulted in a large equipment footprint and a crowded workshop layout; switching between abrasive types was difficult to clean, and residual abrasives easily led to product purity not meeting standards. We provided six mobile abrasive sand flexible screw conveyors, equipped with universal wheels and quick-connect interfaces, allowing a single device to be flexibly switched to different raw material warehouses and production lines.

The single-unit conveying length of the flexible screw conveyor for abrasive sand varies depending on working conditions and drive capacity. In the vertical conveying direction, the lifting height can reach up to 5 meters, effectively achieving direct lifting of abrasive materials from a low position to a high position. In the horizontal conveying direction, the maximum single-unit length can reach 30 meters, meeting the planar layout requirements of most production lines. When the process requires longer distance conveying, the system can be flexibly expanded through a series connection design. This involves connecting multiple conveyors end-to-end for relay conveying, thus overcoming the limitations of a single unit's length.

As a direct manufacturer, our flexible screw conveyor for abrasive sand starts at $50, with the specific price calculated based on customized requirements. Key factors affecting the price include conveying length, pipe diameter specifications, wear-resistant material selection, motor power, and whether special accessories such as anti-clogging and sealing devices are required. We adhere to a factory-direct supply model, eliminating the markup of intermediate distributors, while offering both standardized production and customized services. All equipment includes a basic warranty and free technical solution design, ensuring transparent pricing with no hidden costs, allowing customers to obtain high-quality equipment suitable for abrasive sand conveying conditions at a high cost-performance ratio.

Can the Flexible Screw Conveyor for Abrasive Sand be used for vertical conveying?

Yes. The flexible screw conveyor for abrasive sand fully supports vertical conveying; however, its vertical conveying capacity is limited, with a maximum lifting height of no more than 5 meters. Beyond this height, if the material has good fluidity, it may fail to feed properly.

Can the Flexible Screw Conveyor for Abrasive Sand convey abrasive sand powder?

Yes. It uses a sealed flexible hose with wear-resistant spiral blades, which prevents sand powder from escaping and avoids equipment wear, adapting to the conveying needs of sand powder of different particle sizes.

Which countries can the Flexible Screw Conveyor for Abrasive Sand be exported to?

As a direct manufacturer, our flexible screw conveyor for abrasive sand can be exported to countries worldwide. The equipment supports customization to meet different countries' voltage standards and industrial certifications, and can be adapted to working conditions in various industries such as thermal power, building materials, and metallurgy. We provide full export customs clearance, logistics distribution, and after-sales technical support.

Is the abrasive sand flexible screw conveyor packaged in a wooden crate?

Yes, our abrasive sand flexible screw conveyor is packaged in a sturdy wooden crate. The packaging is customized to fit the equipment dimensions, and the wooden crate meets export shipping standards and can be used directly for various logistics methods such as sea and land transportation.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!