Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

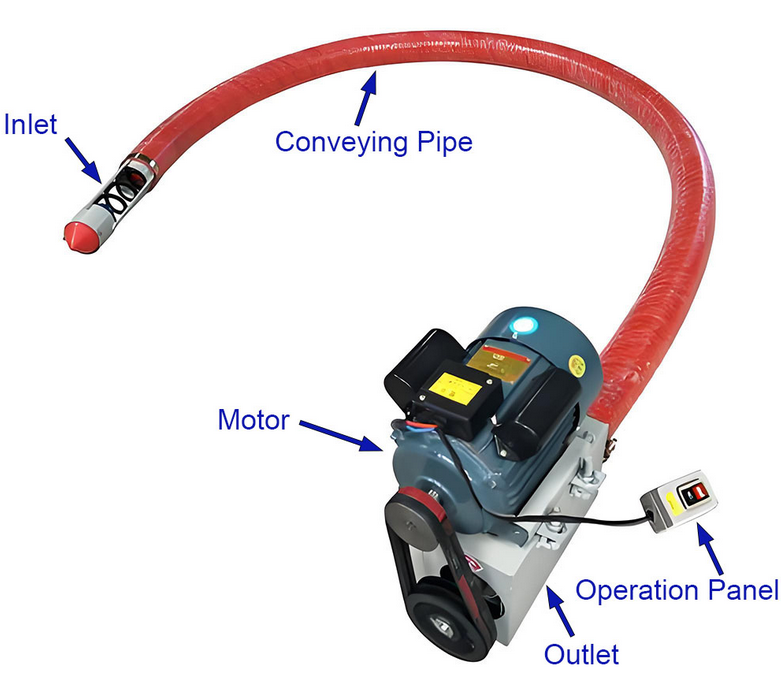

Flexible Grain Auger is an innovative conveying equipment that uses a highly elastic alloy spiral and a wear-resistant composite hose to work together. It is designed for efficient and low-loss conveying of agricultural materials such as grains, seeds, and feed.

Pipeline diameter: 100mm/120mm/160mm

Length: 3-30 meters

Vertical height: 3m-4m

Conveying capacity: 4-20 tons/hour

Voltage: 220/380V or design

Conveying angle: 0-90 degrees

Drive mode: electric/diesel/motor

Suitable for conveying corn, soybeans, rice, wheat, sorghum, millet, quinoa and other grains.

Flexible Grain Auger is a flexible screw conveyor designed for conveying bulk materials such as grains and seeds. It uses a high-strength spring steel screw shaft and a tendon shell, which can be bent freely to adapt to narrow spaces and complex paths. The standard model has a diameter of 100-160mm, a length of 5-30 meters, and a conveying capacity of 2-20 tons/hour. It is suitable for a variety of scenarios such as granaries, food processing, and farms. It supports electric, hydraulic, or diesel drive options, and provides customized services such as stainless steel materials, speed control systems, and explosion-proof designs.

The Flexible Grain Auger is designed with high-strength spring steel spiral and wear-resistant bellows. It is bendable and compact, easily adapting to narrow spaces and offering flexible customization!

Three-dimensional flexible conveying: The spiral spring can be bent by ±30° to bypass obstacles and adapt to narrow space layouts.

Powerful conveying capacity: When a single flexible screw conveyor conveys grain, the vertical height can reach 6 meters, and the horizontal conveying distance can be flexibly adjusted according to actual needs. If multiple conveyors are connected in series, the conveying distance and height can be further improved to meet the needs of large-scale grain transportation.

Fully enclosed conveying and anti-pollution design: The sealed casing structure effectively isolates the external environment to prevent grain from being damp, pests or dust pollution.

Low energy consumption and long life: The design without intermediate bearing support eliminates the blocking failure point of traditional equipment, and the maintenance cycle is extended to more than 2000 hours.

Based on our customers' production needs, we offer two different types of flexible grain augmenters: handheld stainless steel and handheld hose. We can recommend the most suitable Flexible Grain Auger based on your site requirements.

The handheld stainless steel auger conveyor: Utilizing a corrosion-resistant, easy-to-clean stainless steel spiral hose, it is suitable for locations with high hygiene requirements, such as food factories and granaries. It enables precise feeding over short distances of 3-10 meters, while meeting both hygienic and precise conveying requirements.

The handheld hose auger conveyor: Utilizing a wear-resistant cowhide hose, it is lightweight and flexible, making it suitable for temporary feed replenishment on farms and for storage and handling in small warehouses. It can be operated by one person, and with a hose diameter of 100-200 mm, it adapts flexibly to confined spaces, providing exceptional convenience.

The Flexible Grain Auger uses a spring-loaded helical coil and flexible tube to transport grain. A motor drives the spring-loaded helical coil at high speed, generating a spiral thrust within the flexible tube. After entering the feed port, grain is moved forward along the inner wall of the tube by centrifugal force and the spiral thrust. The flexible tube, constructed of a steel wire-framed rubber structure, is flexible and can bend freely, allowing the propulsion force to be applied continuously along complex paths, enabling multi-directional conveying, including straight, inclined, and vertical conveying.

|

Diameter |

Length |

Refer capacity |

|

100mm |

0-30m |

5-7t/h |

|

120mm |

0-30m |

8-10t/h |

|

160mm |

0-30m |

11-20t/h |

The Flexible Grain Auger is composed of a shaftless spiral and wear-resistant tendon hose structure. The pipe diameter is adjustable from 150 to 200 mm and supports horizontal transportation of 30 meters or inclined transportation of 25 degrees, which perfectly solves the problems of grain breakage and residue.

Spiral blades: Usually made of wear-resistant steel or food-grade stainless steel, designed as belt, paddle or solid spiral according to the characteristics of grain to ensure low crushing conveying.

Spiral shaft: Flexible shaft (such as spring steel shaft) or segmented rigid shaft connected by universal joint to achieve bending conveying capacity.

Tendon hose: made of high-density polyethylene or polyurethane, corrosion-resistant and bendable, protecting the internal spiral and preventing dust leakage.

Motor: Usually a variable frequency motor, which can be adjusted to meet different conveying volume requirements.

Suspension bearing: used to support the spiral shaft during long-distance transportation to reduce deflection.

The drive mode of the Flexible Grain Auger needs to be selected based on the working environment, power availability, maneuverability requirements and energy efficiency requirements.

Electric drive: Electric drive is the most commonly used drive mode for flexible grain spiral conveyors. Most equipment uses ordinary three-phase asynchronous motors or variable frequency motors, and is equipped with a reducer to achieve low-speed operation of 20-60rpm.

Diesel engine drive: Diesel engine drive is designed for scenarios without power supply, such as field grain collection and remote grain station transfer. It is often combined with a vehicle-mounted conveyor to achieve flexible operation. It provides 5-50HP power through a single-cylinder or multi-cylinder diesel engine, which is driven by a belt, chain or hydraulic motor.

Motor drive: It is suitable for working conditions with complex conveying paths and high material resistance, such as heavy-duty conveying of high-moisture corn and soybeans. The system is powered by a diesel engine or an electric pump station, and the hydraulic motor directly drives the spiral shaft. It has the characteristics of stepless speed regulation, smooth start and stop, and its small size makes it easy to install in narrow spaces.

Flexible Grain Auger is suitable for many scenarios, especially in narrow, irregular or flexible layouts, due to its bendability, compact structure and adaptability to complex spaces.

Narrow channel transportation: When the internal space of the granary is limited, it can be bent around pillars, stairs or other equipment to transport grain from the entrance to the designated bin.

Corner cleaning: Used to clean the grain remaining in the dead corner of the bottom of the bin to avoid manual handling.

Low space operation: When the height of the carriage is insufficient, the grain is unloaded from the truck to the ground or the receiving port through a flexible screw conveyor to avoid the problem of large equipment being unable to enter.

Short-distance connection between equipment: In a compact food processing plant, it can flexibly cross the gaps between equipment or wall openings to connect crushers, mixers, etc.

Multi-story plant transportation: Inclined + horizontal composite path, conveying grain in an "S" or "U" shaped route between floors, replacing the combination of multiple rigid conveyors.

Field mobile unloading: Cooperate with a small tractor or cart to flexibly adjust the angle to transport grain from the harvester to a temporary grain storage point.

Emergency discharge of blocked silos: When the silo outlet is blocked, insert a flexible screw machine for local dredging.

Flexible Grain Auger's high-strength spring steel spiral + wear-resistant bellows design enables 180° flexible bending, improving conveying efficiency by 40% and reducing energy consumption by 25%.

Horizontal/vertical composite conveying: The maximum conveying distance of a single machine is 30 meters, the vertical lifting height can reach 6 meters, and the maximum inclination angle is 90°, which meets the three-dimensional conveying needs of granaries, docks and other scenes.

Anti-winding and low crushing rate: For granular grains such as corn and wheat, the ribbon spiral blade design is adopted to reduce the crushing rate to less than 0.1%; for fiber-containing materials (such as rice husks), special anti-winding blades can achieve stable conveying.

Weather resistance and explosion-proof design: The operating temperature range is -20℃ to 180℃, which is suitable for high-temperature drying grain transportation; the explosion-proof motor and grounding system are ISO 80079-34 certified and suitable for dust explosion risk environments.

From damage-free wheat transfer at grain depots to emergency corn loading and unloading on farms, to explosion-proof feeding at feed mills, the Flexible Grain Auger, with its multiple drive types and customized design, has successfully helped customers achieve a breakage rate of less than 0.2% and a threefold increase in efficiency.

Wheat Transportation at Large Grain Depots: The customer needed to transfer wheat to silos without breaking grains. The solution was a 200mm diameter, 15-meter long electric flexible screw conveyor equipped with a 304 stainless steel screw and food-grade PU hose.

Corn Loading and Unloading on Farms: The customer needed to quickly load and unload corn in an off-grid environment. The solution was a 250mm diameter, 10-meter long diesel-driven flexible screw conveyor with a movable chassis and wear-resistant steel hose.

Soybean Meal Feeding at Feed Mills: The customer needed to accurately feed powder in an explosion-proof workshop. The solution was a 150mm diameter pipe equipped with anti-static hose and variable frequency speed control.

The Flexible Grain Auger features a spring steel helical shaft and wear-resistant bellows, making it suitable for confined spaces like grain silos and processing plants. The standard version, with diameters ranging from 100-160 mm and lengths from 5 to 30 meters, is priced at $150 per unit. It supports electric, motor, or diesel drive options, with a conveying capacity of 2-20 tons/hour. Custom requirements (such as stainless steel construction and speed control) are available at an adjustable price. Discounts are available for larger quantities.

Flexible Grain Auger supports full customization services. The pipe diameter, length, and material can all be designed according to needs. Electric and diesel drive options are available to ensure that the transportation efficiency is increased by 50% or more.

✓ Customized size: The conveyor diameter and length can be adjusted as needed.

✓ Material upgrade: Food-grade material options such as stainless steel are available.

✓ Function expansion: support special needs such as speed regulation, dust removal, explosion-proof, etc.

✓ Drive adaptation: can match electric, hydraulic or diesel drive systems.

The flexible grain spiral conveyor takes "flexibility" as the core, breaking through the space and working condition limitations of traditional conveying equipment, and has become a key equipment for reducing costs and increasing efficiency in the grain industry. Whether it is a small or medium-sized farm or a large grain company, it can achieve high-speed, safe and green material transportation through customized solutions, providing solid support for the intelligent upgrading of the grain industry chain.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!