Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Adjustable Height Small Grain Auger Screw Conveyor is a new type of conveying equipment designed for small grains (such as millet, sorghum, rapeseed, etc.). It integrates height adjustment function and precision conveying technology to meet the grain conveying needs in different operating scenarios. The equipment adopts modular design, and the conveying height can be adjusted steplessly within the range of 1.2-3.5 meters. It is particularly suitable for use in grain processing plants, seed companies, farms and other places.

In the field of small grain conveying, the adjustable height small grain spiral conveyor stands out with its unique advantages. Its flexible height adjustment function can seamlessly connect various equipment and operating scenarios.

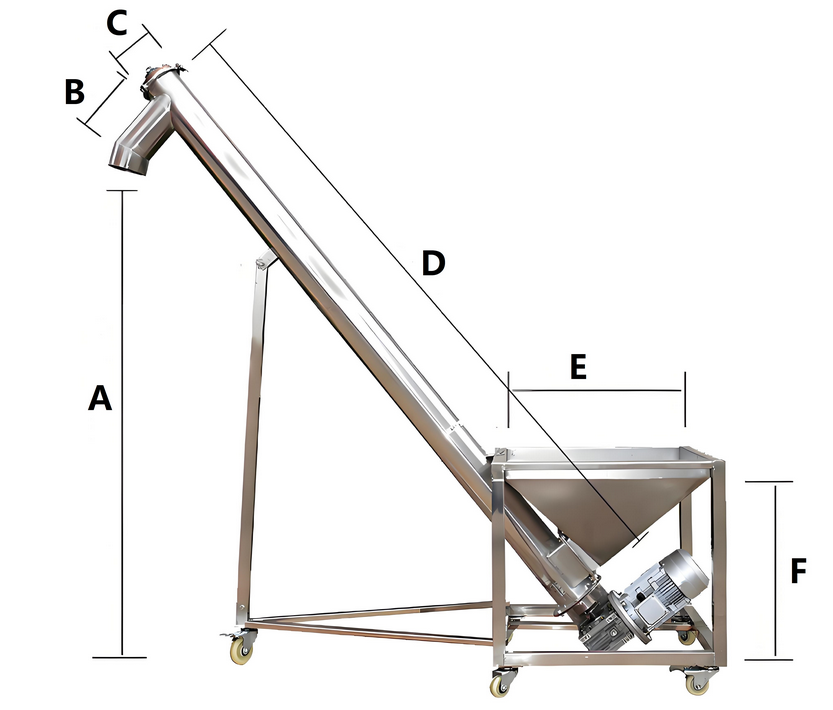

Flexible and adjustable height: 1.2-3.5 meters stepless lifting, adapting to a variety of material receiving equipment.

Low breakage rate: low-speed operation + flexible spiral design, grain breakage rate ≤0.3%.

Sealed and dustproof: fully enclosed pipeline, dust overflow <5mg/m³, in line with environmental protection requirements.

Low energy consumption: 40% lower energy consumption than traditional conveying equipment, and 30% higher conveying efficiency.

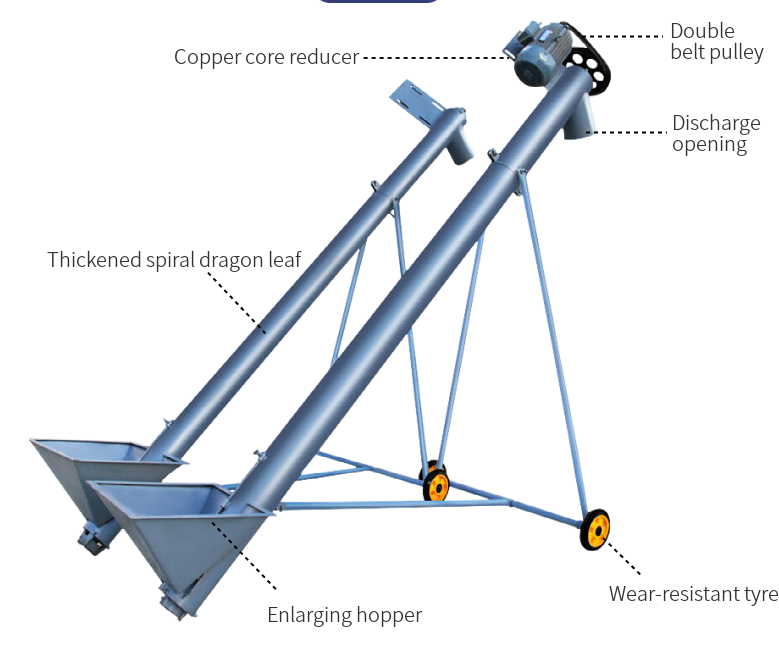

The adjustable height small grain spiral conveyor is mainly composed of the following core components.

Screw shaft: 304 stainless steel or wear-resistant alloy steel, pitch 50-100mm (suitable for small particle materials).

Conveying pipe: fully enclosed design, inner wall polishing or lining wear-resistant coating (such as polyurethane).

Drive device: variable frequency motor + reducer, adjustable speed 15-45rpm.

Support frame: carbon steel or stainless steel structure, with locking device.

Mobile base: universal wheel (with brake) for easy station adjustment.

PLC or manual control panel: preset height and adjust conveying speed.

In the material conveying process, small grains (such as millet, rapeseed, etc.) enter the closed conveying pipe from the feed port, are pushed by the rotating spiral shaft to move smoothly along the pipe, and are finally discharged from the discharge port. The whole process ensures the integrity of the material and the continuity of the conveying. The height adjustment is achieved through a hydraulic or electric lifting mechanism, which can accurately adjust the position of the discharge port within the range of 1.2-3.5 meters, and flexibly adapt to the height requirements of different receiving equipment such as packaging machines and grain storage silos.

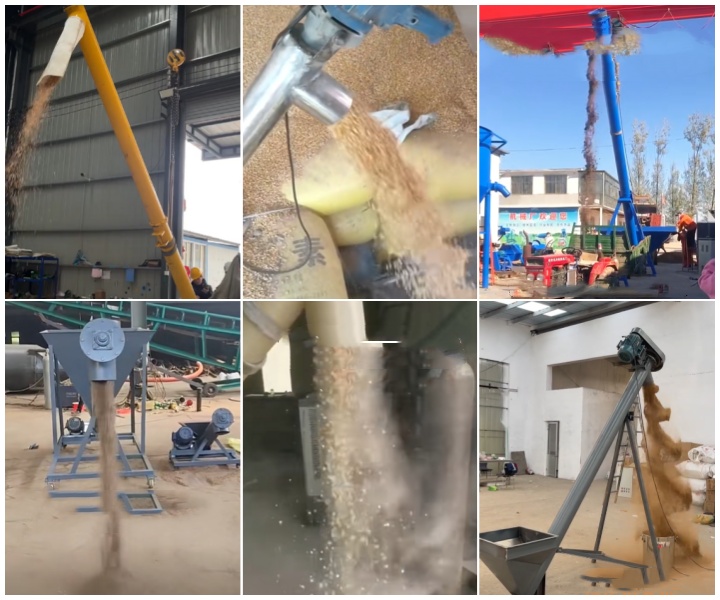

In the field of modern agriculture and food processing, the adjustable height small grain spiral conveyor has become an ideal conveying equipment for multiple scenarios due to its flexible and efficient characteristics.

Seed processing plant: It can convey small seeds such as millet, sorghum, and rapeseed. It adopts a closed conveying pipeline. The whole process from raw material reception, selection to packaging can prevent the mixing of seeds of different varieties and ensure the purity of seeds.

Grain storage and loading and unloading: The adjustable height small grain spiral conveyor can flexibly adjust the height and achieve precise docking with truck compartments and grain storage bins of different heights.

Food processing workshop: The transportation of small grain raw materials such as seasonings and sugar grains requires extremely high equipment hygiene standards. The adjustable height small grain spiral conveyor is made of food-grade stainless steel. The inner wall is smooth and has no dead corners. It is not easy to leave raw materials. It is easy to clean and disinfect, effectively preventing the growth of microorganisms and raw material contamination, and strictly complies with food safety production standards.

Organic farms: Organic farms grow a wide variety of crops, with flexible and changeable site layouts, and often face material transportation problems due to adjustments in planting areas and temporary storage needs. The adjustable height small grain spiral conveyor has become a powerful assistant for organic farms to handle small grain crops with its flexible height adjustment and simple installation and disassembly characteristics.

The inclination angle adjustment range of the adjustable height small grain spiral conveyor depends on the specific model and design. Generally speaking, the common adjustable inclination angle range is as follows.

Minimum inclination angle: Usually close to horizontal, that is, 0 degrees or slightly greater than 0 degrees (for example, 5 degrees).

Maximum inclination angle: The common maximum inclination angle is between 15 degrees and 30 degrees. Some specially designed models can reach 45 degrees or even greater.

Factors affecting the adjustment range of the inclination angle:

Design of spiral blades: Specially designed spiral blades (such as blades with retaining edges) can improve the conveying capacity and allow a larger inclination angle.

Material characteristics: The particle size, humidity, viscosity and other characteristics of the material will affect the maximum inclination angle of the conveyor. For materials that are easy to slide, the inclination angle should not be too large.

Conveyor length: For longer conveyors, the inclination angle is usually limited to ensure the stability of the conveying.、

Choosing a suitable adjustable height small grain screw conveyor is crucial to ensuring operating efficiency and reducing costs.

Small operations: For small farms, township grain processing sites and other small operation scenarios, due to the relatively small amount of material handling, the daily conveying volume is usually 1-5 tons, and the operation time is discontinuous. It is recommended to choose a model with a pipe diameter of Φ150mm. This pipe diameter specification can meet the transportation needs of small batches of grains. The spiral blade design is compact, and with a 1.5kW motor, the power output is stable and the energy consumption is low.

Continuous production: In large-scale grain processing plants, large-scale grain warehouses and other scenarios that require long-term continuous production, the grain conveying volume is large, and the daily conveying volume can reach tens of tons or even hundreds of tons. At this time, it is recommended to use a Φ300mm diameter conveyor with a 5.5kW motor and a variable frequency control system. A larger pipe diameter can accommodate more materials, and with a high-power motor, it can achieve efficient transportation of 10-20 tons per hour.

Flammable and explosive production: When there are flammable and explosive risks in the working environment, such as grain warehouses storing high concentrations of dust, or in workshops where flammable liquids such as ethanol are used to pre-treat grains, it is necessary to choose a conveyor equipped with an explosion-proof motor as a safety guarantee. The explosion-proof motor uses special sealing, insulating materials and structural design to effectively prevent electric sparks and high temperatures generated during motor operation from causing explosion accidents.

Remote monitoring system: In large-scale grain storage bases, intelligent agricultural parks and other scenarios, a remote monitoring system can be configured to achieve intelligent management and remote operation and maintenance of equipment. The system transmits the operating status, fault information, conveying volume and other data of the conveyor to the monitoring center in real time through the Internet of Things technology.

The adjustable height small grain spiral conveyor plays an increasingly important role in modern grain logistics with its flexible height adjustment capability and efficient conveying performance. It not only improves operating efficiency and reduces labor intensity, but also lays the foundation for the automation and intelligence of grain transportation.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!