Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Water Cooling Spiral Vibrating Conveyor combines vibration and cooling methods and can be used to convey cooled and dried materials upward/downward.

Conveyor trough diameter: 300-900mm Height: ≤6 meters

Transportation capacity: 3.5 tons/hour

Power: 2* (0.4-3)kw

Frame material: SU 304/carbon steel

Speed: adjustable speed

Customization: upper vibration, lower vibration, air cooling, water cooling, locking, opening, 360-degree feeding, etc.

Use: used for conveying and lifting powdery, blocky and short fiber materials.

Promise: free shipping/5-day delivery/30-day return/support customization

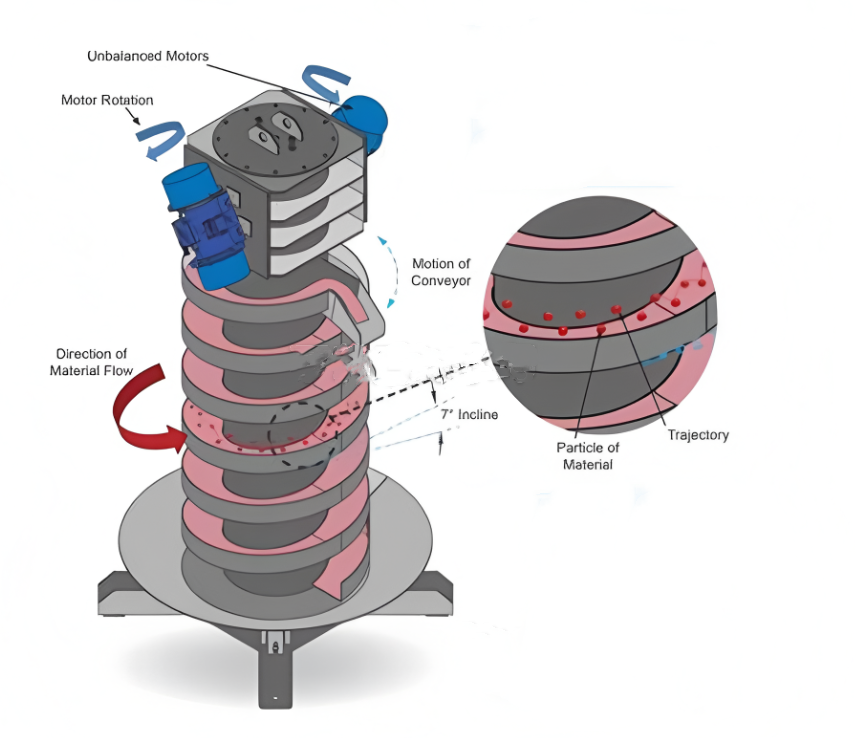

Water Cooling Spiral Vibrating Conveyor is mainly used for rapid cooling and drying of materials. It combines the characteristics of screw conveyor and vibrating conveyor, and achieves the effect of cooling and conveying through screw push and vibration transmission. The vibration method also improves the fluidity of materials and prevents blockage.

Combining screw conveying and water cooling, the cooling effect is remarkable.

Vibration conveying can effectively prevent materials from agglomerating under high humidity, resulting in poor conveying effect.

It adopts the principle of vertical conveying, occupies a small area, and is convenient for process layout.

It can effectively solve the problem that the body of ordinary screw conveyors is unstable or the conveying cannot be completed after being higher.

Water-cooled spiral vibrating conveyors are usually used to convey high-temperature or cooling materials.

High-temperature metal slag and slag: High-temperature metal slag and slag just produced can be cooled and conveyed by water-cooled spiral vibrating conveyors.

High-temperature chemical raw materials: Some molten plastics, high-temperature chemicals, etc. in chemical raw materials can be conveyed and cooled by water-cooled spiral vibrating conveyors.

Cement clinker: Water-cooled spiral vibrating conveyors can be used to convey high-temperature cement clinker to help cool and process it.

High-temperature food: In food processing, some products made at high temperatures can be conveyed and cooled by water-cooled spiral vibrating conveyors.

| Model | Diameter of Spiral chute(mm) |

Lifting height

(m)

|

Speed (rpm) |

Double amplitude

(mm)

|

Power

(kw)

|

| DZC-500 | 50 | ≤6m | 960 | 6-8 | 2*0.75 |

| DZC-600 | 600 | ≤7m | 2*1.5 | ||

| DZC-800 | 800 | 2*2.2 | |||

| DZC-1000 | 1000 | 2*3.0 | |||

| DZC-1200 | 1200 | 2*4.5 | |||

| DZC-1500 | 1500 | 2*5.5 | |||

| DZC-1800 | 1800 | 2*6.0 |

The choice of water-cooled vertical spiral vibrating conveyor on different materials usually depends on the specific application requirements and environmental conditions.

Stainless steel water-cooled vertical spiral vibrating conveyor: Suitable for handling corrosive materials and in the food processing industry. Stainless steel has a smooth appearance, is easy to clean, and has good wear resistance and durability.

Carbon steel water-cooled vertical spiral vibrating conveyor: Carbon steel has higher strength and is suitable for handling heavier materials or using in high-load working environments. Compared with stainless steel, carbon steel has a lower manufacturing cost and is suitable for occasions with limited budgets.

Screw conveyor body: It is composed of a screw conveyor shaft and a spiral blade. The spiral blade has two types: pull-in type and full pull-in type.

Inlet and outlet: The feed unit and the discharge unit are respectively set at both ends of the cylinder to facilitate the entry and exit of materials.

Flange: It is used to connect the screw conveyor body with other equipment to ensure the tightness and sealing of the connection.

Vibration reduction system: It includes shock-absorbing springs, etc., which are used to reduce the impact of vibration on the equipment.

The working principle of the water-cooled vertical spiral vibrating conveyor is to use the asymmetric principle of the vibration motor to generate a vibration couple, and through the vibration of the shock-absorbing spring, the material is lifted from the horizontal to a certain height. At the same time, the cooling system inside the equipment effectively reduces the temperature of the material through the flow of cooling water and the principle of heat exchange.

Our water-cooling spiral vibrating conveyor adopts advanced cooling system, which can effectively reduce the temperature of high-temperature materials and ensure the smooth progress of the production process. We have an experienced engineering and technical team with professional skills and knowledge required to design, manufacture and install water-cooling spiral vibrating conveyors. , using advanced production technology and high-quality raw materials to ensure the quality and reliability of water-cooling spiral vibrating conveyors, we provide pre-sales consultation, customized design, in-sales support and after-sales service.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!