Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Vibrating conveyor uses vibration to use flexible conveyor belt as the load-bearing component. Through a special vibration drive device, the conveyor trough or conveyor belt makes reciprocating motion in a certain direction, thereby driving the material forward along the conveying direction.

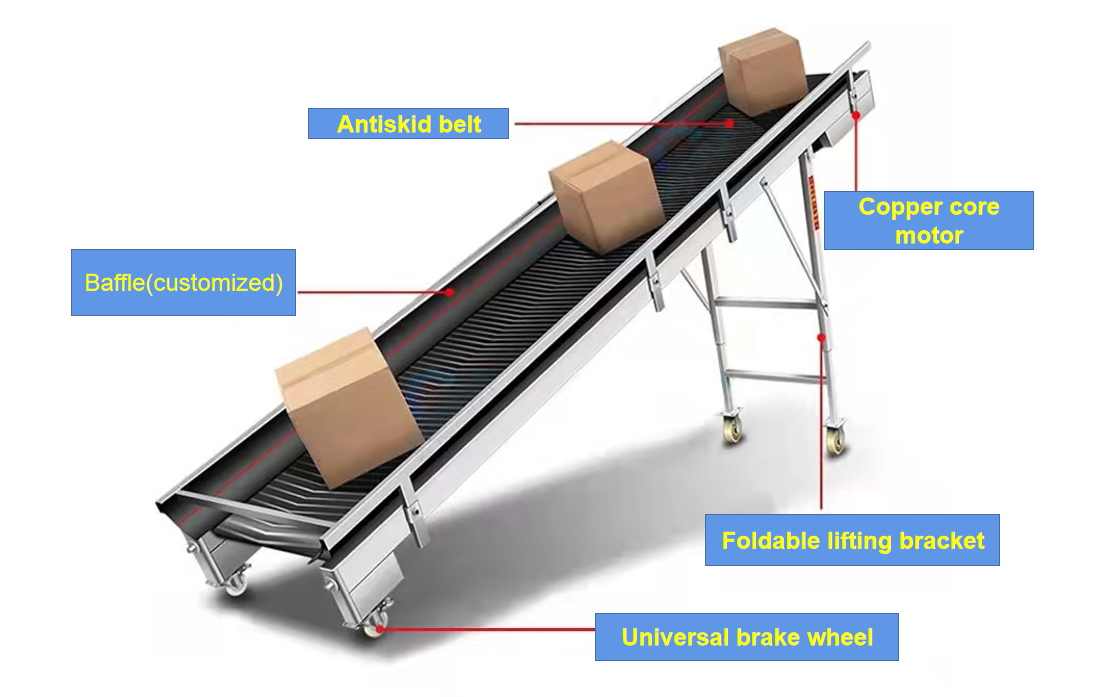

Belt width: 400/500/650/600/800/1000/1200/1500mm

Conveying speed: 1.25-2m/s

Conveying length: 30 meters

Belt material: PVC/PU rubber

Frame Material: Carbon Steel/Stainless Steel

Angle: 0°-90°

Application: The material can be transported from the initial feeding point to the unloading point inclined or vertically, used in chemical, electronic, food processing and other industries

Vibrating Conveyor uses vibration to transport materials along the belt. It uses a flexible conveyor belt as a load-bearing component and uses a special vibration drive device to make the conveyor belt vibrate at a high frequency and a small amplitude. This vibration can effectively reduce the friction resistance between the material and the conveyor belt, improve the conveying efficiency, and has a certain self-cleaning ability.

The advantages and characteristics of Vibrating Conveyor are mainly as follows.

Prevent material blockage: Vibration can make the material jump or slide slightly on the belt, which can effectively prevent material accumulation or blockage, and is particularly suitable for conveying materials with high viscosity or easy to agglomerate.

Protect material integrity: The vibration frequency and amplitude are adjustable, which can reduce the impact and wear on the material, and is particularly suitable for conveying fragile or brittle materials.

Uniform conveying: It can achieve uniform distribution and continuous conveying of materials, avoiding accumulation or faults of materials during conveying.

Adapt to a variety of materials: It can handle various types of materials, including granular, powdery, blocky, sticky materials, etc., with strong adaptability.

Easy to clean and maintain: The structure is simple, without complex transmission parts, easy to clean and maintain, reducing downtime and maintenance costs.

Can be linked with other equipment: It can be seamlessly connected with other equipment (such as screening machines, dryers, etc.) to achieve automated production.

Reduce material stratification: Through vibration, it can reduce the stratification of materials during transportation and ensure that the materials are evenly mixed.

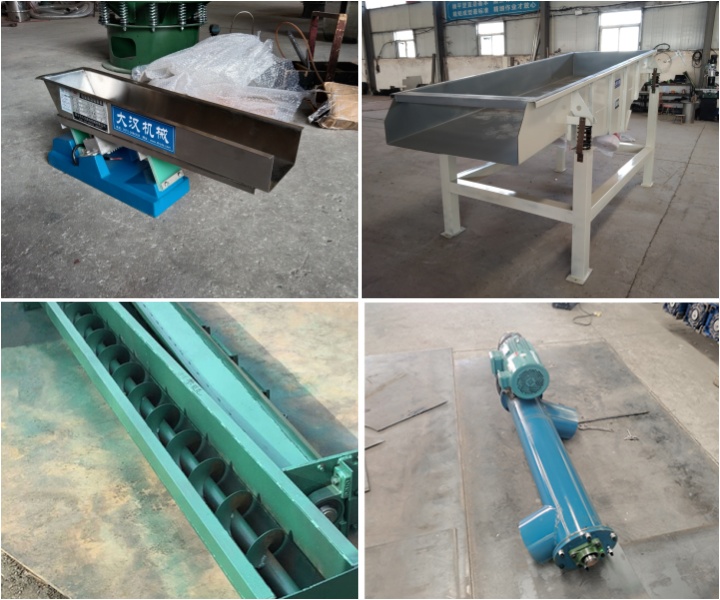

According to different structures and driving methods, vibrating conveyors can be divided into many types:

Linear vibrating conveyor: The conveying trough or conveyor belt mainly reciprocates in a straight line. This is the most common type.

Spiral vibrating conveyor: The conveying trough is spiral-shaped, and the material rises or falls along the spiral trajectory while vibrating. Commonly used for vertical or inclined transportation.

Electromagnetic vibrating conveyor: The excitation force is generated by an electromagnetic vibrator. It has a compact structure, low noise, and is easy to achieve stepless speed regulation and automatic control, but the conveying capacity is relatively small.

Hydraulic vibrating conveyor: The excitation force is generated by a hydraulic cylinder or hydraulic motor drive. The conveying capacity is large and the vibration parameters are adjustable, but the structure is complex and the cost is high.

Trough type vibrating conveyor: It uses a closed or semi-closed trough as a conveying component, which is suitable for conveying powder, granular and small block materials.

Tube type vibrating conveyor: It uses a closed tubular structure as a conveying component to achieve closed conveying, prevent dust flying and material pollution.

Belt type vibrating conveyor: It uses a flexible conveyor belt as a conveying component, supported by rollers and driven by a vibrating device. It is suitable for conveying bulk materials or finished items over a long distance.

The core of the vibrating belt conveyor lies in the combination of its vibration system and conveyor belt. Its working principle is as follows:

Vibration source: The vibrator is driven by an electric motor to make the conveyor generate high-frequency vibration.

Material conveying: The material is pushed by the vibration on the belt and moves forward along the conveyor belt. This vibration not only keeps the material in a flowing state on the conveyor belt, but also effectively avoids the accumulation and congestion of materials.

Discharge port: The material passes through the conveyor belt and is finally discharged smoothly from the discharge port to complete the conveying process.

Vibrating Conveyor is mainly composed of the following parts.

Conveyor belt: Usually a ring-shaped or open belt made of rubber, plastic or other special materials, used to carry and convey materials.

Driving device: Including motor, reducer and vibrator. The vibrator is the core component that generates vibration force. Common ones include eccentric block vibrator, cam vibrator, etc.

Support device: It is composed of rollers, frames, etc., used to support the conveyor belt and materials and ensure the normal operation of the conveyor belt. Unlike ordinary belt conveyors, the rollers of vibrating belt conveyors usually have a certain elasticity or special structure to adapt to the vibration of the conveyor belt.

Tensioning device: Used to adjust the tension of the conveyor belt, ensure the friction between the conveyor belt and the drive roller, and prevent slipping.

| Model | Length | hight | Power |

| B500 | 3-10m | 1-4m | 0.75-1.1KW |

| B600 | 3-10m | 1-4m | 0.75-1.1KW |

| B800 | 4-10m | 1.5-4m | 1.1-2.2KW |

Vibrating Conveyor is widely used in different industries.

Food industry: used to transport various food raw materials, semi-finished products and finished products, such as grains, candies, biscuits, etc. In the food production line, the vibrating belt conveyor can quickly and hygienically transport materials to various processing links.

Pharmaceutical industry: used to transport pharmaceutical granules, capsules, tablets, etc. in the process of drug production. Its precise conveying control and good hygienic performance can meet the strict quality requirements of the pharmaceutical industry for material transportation.

Chemical industry: suitable for conveying various chemical raw materials and products, such as fertilizers, plastic granules, pigments, etc. It can operate stably in harsh chemical production environments and has good adaptability to materials of different chemical properties.

Mining industry: can be used to transport ore, coal and other materials. In the process of mining and processing, the vibrating belt conveyor can efficiently transport the mined ore to subsequent processes such as ore dressing and crushing, thereby improving the production efficiency of the mine.

Building materials industry: used to transport building materials such as cement, sand, gravel, bricks, etc. Its strong conveying capacity and adaptability to heavy-loaded materials play an important role in building materials production and construction.

As a conveying manufacturer, we have customers in different industries who use it widely. The following four cases show the wide application of vibrating belt conveyors in the food, chemical, mining and pharmaceutical industries.

Case 1: Flour processing plants need to transport flour from the production line to the packaging workshop, but because flour is easy to generate dust and has strong fluidity, traditional conveying equipment is prone to dust pollution and material waste. The use of vibrating belt conveyors, equipped with a closed design, effectively prevents flour from generating dust.

Case 2: Chemical raw material companies need to transport granular chemical raw materials, but because the raw materials are easy to agglomerate and corrosive, traditional conveying equipment is prone to clogging and severe wear. Vibrating belt conveyors made of corrosion-resistant materials are selected. The vibration function prevents material agglomeration and ensures continuous and uniform transportation.

Case 3: Ore companies need to transport crushed ore from the crusher to the screening equipment, but because the ore particles are of different sizes and contain impurities, traditional conveying equipment is prone to jamming. Heavy-duty vibrating belt conveyors are used. The vibration function effectively prevents large-particle ore from jamming, while adapting to the needs of inclined transportation.

Case 4: The pharmaceutical factory needs to transport the powder from the mixing equipment to the packaging line, but because the powder has extremely high hygiene requirements and needs to maintain the integrity of the material, traditional conveying equipment is difficult to meet the needs. The vibrating belt conveyor made of food-grade stainless steel is equipped with a closed design and adjustable vibration function to ensure that the powder is not polluted or damaged during transportation.

Choosing a suitable vibrating conveyor is a complex process that requires comprehensive consideration of multiple factors such as material characteristics, conveying requirements, working environment, and economy. The following are the main factors to be considered when selecting and designing a vibrating conveyor in detail:

Material type: Different materials (such as granular, powdery, lumpy, sticky materials, etc.) have different requirements for vibrating conveyors.

Particle size: The particle size of the material affects the design and vibration parameters of the conveyor.

Shape: The shape of the material (such as round, flake, fibrous, etc.) will affect the conveying effect.

Density: The density of the material determines the carrying capacity and vibration intensity of the conveyor.

Humidity: Materials with too high humidity may cause adhesion or agglomeration, requiring special design.

Viscosity: Viscous materials tend to adhere to the conveyor trough, so it is necessary to select anti-sticking materials or increase the vibration intensity.

Temperature: High-temperature materials require high-temperature resistant materials or cooling devices.

Conveying distance: The length of the conveying distance affects the design and power configuration of the conveyor. Long-distance conveying may require segmented design or increased power.

Horizontal conveying: Suitable for most scenarios, the design is relatively simple.

Inclined conveying: It is necessary to select appropriate vibration parameters according to the fluidity and inclination angle of the material.

Vertical conveying: Suitable for occasions with limited space, but the design is complex, and it is necessary to ensure that the vibration intensity is sufficient.

Dust concentration: High dust environment requires a closed design to prevent dust leakage.

Corrosiveness: Corrosion-resistant materials (such as stainless steel) need to be selected in corrosive environments.

Explosion-proof requirements: Explosion-proof vibration motors need to be selected in flammable and explosive environments.

Vibrating belt conveyors have become an indispensable material conveying equipment in modern industrial production with their unique working principle, reasonable structural design, significant advantages and wide application fields. With the continuous advancement of science and technology and the growing demand for industrial production, vibrating belt conveyors will continue to innovate and develop, providing more reliable support for efficient production in various industries.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!