Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Truck Loading Portable Conveyor is a material conveying equipment that integrates mobility, scalability and high efficiency.

Belt width: 400-1200mm

Fixed length: 3-26 meters

Extended length: 2.8-14 meters (can be customized)

Number of conveyor sections: two-section, three-section, four-section

Capacity: 50-400T/H

Power: 8.5KW-18KW (depending on the length)

Application: Typically used in warehouses, distribution centers and shipping facilities for loading and unloading trucks and containers. They are also used in manufacturing plants and assembly lines to transport materials to different workstations.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Truck Loading Portable Conveyor adopts high-strength and lightweight body, equipped with universal wheel/track chassis, which can be quickly moved and deployed. It supports multiple conveying methods such as belt/spiral/hose, suitable for different materials such as bulk materials, packages, powders, etc., and the conveying capacity can reach 100 tons/hour. Optional telescopic, large-angle or closed dust-free design to meet the rapid loading and unloading needs of logistics, construction, grain and other industries.

Adopting high-strength and lightweight design, it is flexible to move and can be quickly deployed to the truck loading and unloading point; the conveying angle and length are adjustable to adapt to different models and materials!

Telescopic design: The body can be freely retracted, and the length can be adjusted according to the depth of the car body. It can be extended to more than 18 meters at most to meet the loading and unloading needs of different models.

Quick deployment: The equipment is easy to move, without complex installation, and can be deployed and debugged within a few minutes, greatly shortening the loading and unloading preparation time.

Multi-angle adjustment: supports multiple conveying modes such as horizontal, inclined, and vertical, and adapts to cargo platforms and carriages of different heights.

Wear-resistant belt: The conveyor belt adopts a herringbone anti-slip design, contains a nylon line reinforcement layer, is heat-resistant, cold-resistant, wear-resistant, and has a long service life.

Leak-proof design: Side ducts are installed on both sides of the frame to prevent goods from falling; the feed hopper is equipped with an adjustment handle to prevent bulk material from leaking.

Intelligent control: The electrical control box integrates start, stop buttons and indicator lights, supports overload protection and phase loss protection, and is simple and safe to operate.

Three types of truck loading portable conveyors: large-angle belt conveyors, telescopic belt conveyors, and hose conveyors to meet the loading and unloading of bulk materials/packages/powders!

Large-angle conveyor: With a high-angle conveying capacity of 30°-60°, it can directly transport bulk materials such as grain, sand and gravel from the ground to the truck cargo box, and is equipped with a patterned sidewall belt or bucket structure to prevent materials from slipping. The advantages are that it saves site space, has a large conveying capacity (20-100 tons/hour), and is foldable for easy mobile storage. It is often used for grain storage loading, sand and gravel loading at construction sites, and coal transshipment at ports.

Telescopic conveyor: The length can be adjusted between 6-18 meters. It can flexibly cover different truck cargo box depths through electric hydraulic control, and is suitable for express parcels, bagged building materials and other materials. Its loading and unloading efficiency is more than 50% higher than that of manual labor. It supports horizontal and inclined combined transportation and is widely used in express loading in logistics sorting centers, supermarket cargo distribution, and factory finished product delivery.

Truck hose conveyor: It uses wear-resistant hoses to achieve flexible bending transportation, and the fully enclosed design eliminates dust flying. It is suitable for granular/powdered materials such as feed and cement powder. It has the advantages of environmental protection and dust-free, remote control to reduce manual contact, and can operate in small spaces such as containers. It is commonly used in wheat loading in grain processing plants, powdered raw material transportation in chemical plants, and pellet loading in feed plants.

A truck loading portable conveyor is a mobile and flexible continuous conveying equipment, mainly used for fast loading and unloading of bulk materials or packaged goods. Its core working principle is to transport materials from the ground or warehouse to the truck cargo box through a motor-driven belt or screw mechanism, greatly improving loading and unloading efficiency.

Due to its flexible movement and high-speed loading and unloading characteristics, truck loading portable conveyors are widely used in different scenarios.

Logistics warehousing and express sorting: In e-commerce warehouse shipments, express loading and container loading and unloading scenarios, telescopic belt conveyors can accurately dock with truck compartments and reduce manual handling through dynamic length adjustment.

Material loading and unloading at construction sites: For loading of sand, cement, bricks and feeding of concrete mixing stations, large-angle belt conveyors are designed with a 30°-45° tilt conveying design to directly lift ground materials to the truck cargo box.

Agricultural production and grain transportation: In the scene of grain, feed, fertilizer loading and field grain collection, the hose conveyor adopts a dust-free and closed design to prevent grain spillage and loss. The lightweight body is easy to move flexibly on the farm mud and is suitable for field working environment.

Bulk cargo loading and unloading at port terminals: When used for short-distance transportation of bulk cargo such as coal, ore, and salt, the heavy-duty belt conveyor can handle more than 100 tons of materials per hour.

Chemical and powder industry: In response to the needs of loading fertilizers, plastic particles, and powdered chemicals, the fully enclosed design of the hose conveyor eliminates the risk of dust explosion.

Food and cold chain logistics: Suitable for frozen products, grain, oil, and beverage loading scenes, using food-grade PU belts, easy to clean and avoid material contamination.

| Type | section | Fixed Length (A) | Extension length (B) | Total Length (C) | Belt Length (W) |

| DH-2-6A/4B | 2 | 6000 | 4000 | 10000 | 600/800 |

| DH-3-5A/7B | 3 | 5000 | 7000 | 12000 | 600/800 |

| DH-3-6A/8.6B | 3 | 6000 | 8600 | 14600 | 600/800 |

| DH-4-5A/10B | 4 | 5000 | 10000 | 15000 | 600/800 |

| DH-4-6A/12.6B | 4 | 6000 | 12600 | 18600 | 600/800 |

| Model | Belt Width (mm) | Lenth(m) | Belt Speed (m/s) | Lifting Height | Slope Angle | Capacity (m³/h) |

| DY-500 | 500 | Max.20 | 0.8-2.0 | adjustable | 0-30 | 50-140 |

| DY-650 | 650 | Max.20 | 0.8-2.0 | adjustable | 0-30 | 100-250 |

| DY-800 | 800 | Max.25 | 0.8-2.0 | adjustable | 0-30 | 170-350 |

| DY-1000 | 1000 | Max.25 | 0.8-2.0 | adjustable | 0-30 | 270-550 |

|

Model |

Pipe diameter |

length |

Installation |

Motor phase power(kw) |

|

RLS-100 |

100mm |

3-30m |

Vehicle mounted |

Single phase 3kw |

|

RLS-120 |

120mm |

3-30m |

Vehicle mounted |

Single phase 4kw |

|

RLS-160 |

160mm |

3-30m |

Vehicle mounted |

Single phase 5.5kw |

|

RLS-180 |

180mm |

3-30m |

Vehicle mounted |

Single phase 11kw |

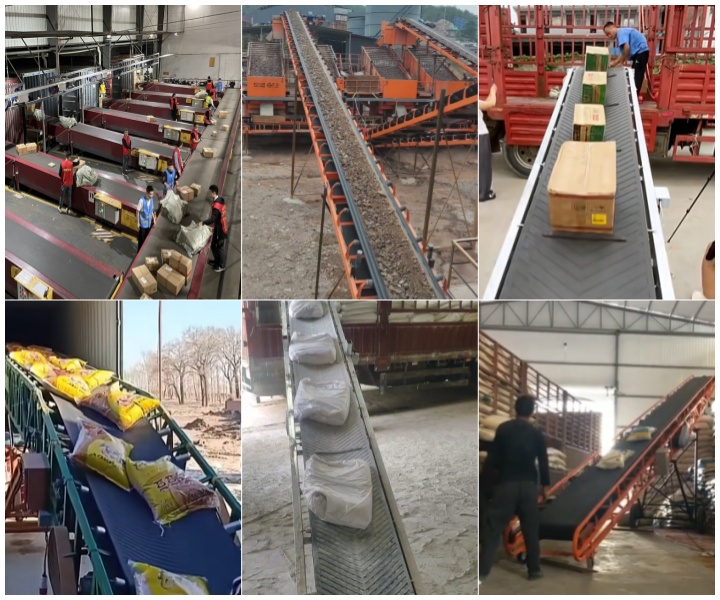

Selected customer cases show the excellent performance of portable conveyors in different scenarios!

Logistics and express delivery: 50,000 parcels per day rely on manual loading, 8 people/shift takes 4 hours/car, and the error rate is high. Solution: Deploy an 18-meter electric telescopic belt conveyor, dock the end of the sorting line and integrate a barcode scanner. The loading time is reduced to 1.5 hours/car, and the efficiency is increased by 60%.

Construction site: The forklift loads sand and gravel at only 30 tons per hour, and the dust pollution is serious and the vehicles are crowded. Solution: Use a large-angle sidewall belt conveyor with a bandwidth of 800mm and an inclination of 45°, equipped with a dust suppression spray system. The loading speed reaches 80 tons/hour, and the vehicle turnover rate is increased by 2 times.

Grain processing: The dust loss rate of manual flour loading is 3%, and the dust is harmful to the health of workers. Solution: Use a food-grade 304 stainless steel closed hose pneumatic conveyor, and match it with a dust removal device to achieve fully enclosed filling. "Zero dust" operation reduces the loss rate to 0.5% and the loading efficiency is 40 tons/hour.

Choosing a suitable truck loading portable conveyor requires comprehensive consideration of factors such as material characteristics, operation scenarios, and efficiency requirements.

Select the model according to material characteristics: For bulk materials, a large-angle belt conveyor or hose conveyor can be selected, and attention should be paid to anti-spillage and wear resistance; packaging is suitable for telescopic belt conveyors, relying on their precise positioning and adjustable length characteristics.

Determine the configuration according to the operation scenario: Folding or telescopic conveyors are preferred for narrow sites; diesel-powered models are required for scenes without power supply. For truck types, vans are suitable for telescopic belt conveyors, open trucks are suitable for large-angle belt conveyors (, and tank trucks require hose conveyors.

Performance parameter matching: In terms of conveying capacity, light-duty requirements can choose 300mm bandwidth and 1.5kW motor; heavy-duty requirements require 800mm bandwidth and 7.5kW motor. Fixed-length belt conveyors are used for short-distance conveying distances, and telescopic or segmented splicing designs are used for long-distance conveying.

Special function additions: Chemical, grain processing and other scenarios require explosion-proof certification; logistics billing and production batching can be equipped with weighing systems.

Dahan Machinery Manufacturing Co., Ltd. is a senior manufacturer specializing in the production of conveyors. It has many years of industry experience and provides a full range of solutions for large-angle belt conveyors, telescopic and hose conveyors. The company uses high-strength steel/aluminum alloy materials, supports customization of bandwidth from 300 to 1000mm, is equipped with wear-resistant rubber/PVC/food-grade PU belts, and can expand intelligent functions such as variable frequency speed regulation, hydraulic lifting, weighing and scanning. It has successfully served many companies, with loading efficiency increased by up to 70%. The products have passed CE, ISO9001 and other certifications, providing 24-hour rapid response. If you are worried about transportation, you might as well contact us to make a detailed plan for you!

In modern logistics, construction and agricultural production, fast and efficient loading and unloading operations are the key to improving work efficiency. The truck-mounted portable conveyor is designed to solve this demand. It combines portability, efficiency and versatility, making it an ideal choice for various loading and unloading scenarios.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!