Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Stainless steel grain suction machine for feed focuses on the needs of the grain and feed industries. It is made of all 304/316L stainless steel, meets food-grade hygiene standards, and has the characteristics of corrosion resistance, rust resistance, and easy cleaning. It uses the principle of negative pressure pneumatic conveying to achieve 5-50 tons per hour and a maximum conveyance of 10 meters. With the fully enclosed pipeline design, it is dust-free and environmentally friendly. The optimized airflow control makes the grain breakage rate less than 0.5%, and the equipment supports universal wheels or vehicle-mounted flexible movement.

In the feed and grain industry, different types of stainless steel grain suction machines can meet different operational needs. According to the power source, there are two common types: electric motor drive and diesel drive.

Motor-driven grain suction machine: usually suitable for a stable power supply of 220V or 380V. Single-phase or three-phase motors can accurately control the operation of the equipment and are suitable for places with reliable power supply, such as feed mills, large granaries, etc.

Diesel-driven grain suction machine: has strong mobility and independence. They are not restricted by power supply and can be used in field farms, temporary construction sites or remote areas with unstable power supply. For example, in rural fields, farmers can directly use diesel grain suckers to load harvested grains.

The working principle of a stainless steel grain sucker for feed is usually as follows:

Suction of feed: The stainless steel grain sucker creates a negative pressure environment through a built-in suction fan or vacuum pump, so that negative pressure is formed in the pipeline, thereby sucking feed particles or powder.

Conveying feed: Once the feed is sucked into the pipeline, it will be transported through the pipeline to the target location, such as a feed mixer, crusher, granulator and other equipment.

Control system: The stainless steel grain sucker is usually equipped with a control system that can adjust the speed, amount and direction of suction and conveying to ensure accurate delivery of feed.

Filtration system: To prevent foreign matter from entering the pipeline or equipment, the stainless steel grain sucker is usually equipped with a filtration system that can filter out large particles or foreign matter in the particles.

Stainless steel grain suckers for feed are widely used in feed production and processing, mainly including the following aspects:

Feed production line: Stainless steel grain suckers are often used in feed production lines to absorb, transport and mix feed raw materials to ensure the continuity and efficiency of the production line.

Feed processing equipment: In feed processing equipment, stainless steel grain suckers can be used to transport various feed raw materials to crushers, mixers, granulators and other equipment to realize feed processing and production.

Feed storage system: Stainless steel grain suckers can also be used in feed storage systems to transport feed particles from storage bins to production lines to realize automatic transportation and supply of feed.

Feed batching system: In feed batching systems, stainless steel grain suckers can be used to accurately absorb and transport various feed raw materials to ensure the accuracy and stability of feed ratios.

Feed packaging line: Stainless steel grain suckers are also commonly used in feed packaging lines to transport finished feed to packaging machines to realize automatic packaging and boxing of feed.

Stainless steel grain suckers for feed have many advantages, and the following are some of the main advantages:

Corrosion resistance: Stainless steel has good corrosion resistance, can resist corrosive substances that may exist in feed, and maintain the long-term stability of the equipment.

Sanitary and safe: Stainless steel meets food hygiene standards and does not produce harmful substances, ensuring the hygiene and safety of feed.

Wear resistance: Stainless steel grain suckers have high wear resistance, can maintain good working condition for a long time, and extend the service life of the equipment.

Easy to clean: The surface of stainless steel is smooth, easy to clean and disinfect, which is conducive to keeping the equipment hygienic and clean.

High strength: Stainless steel has high strength and hardness, can withstand greater working pressure and load, and ensure the stability and safety of the equipment.

Wide applicability: Stainless steel grain suckers are suitable for the absorption and transportation of various feed particles, and have strong versatility and applicability.

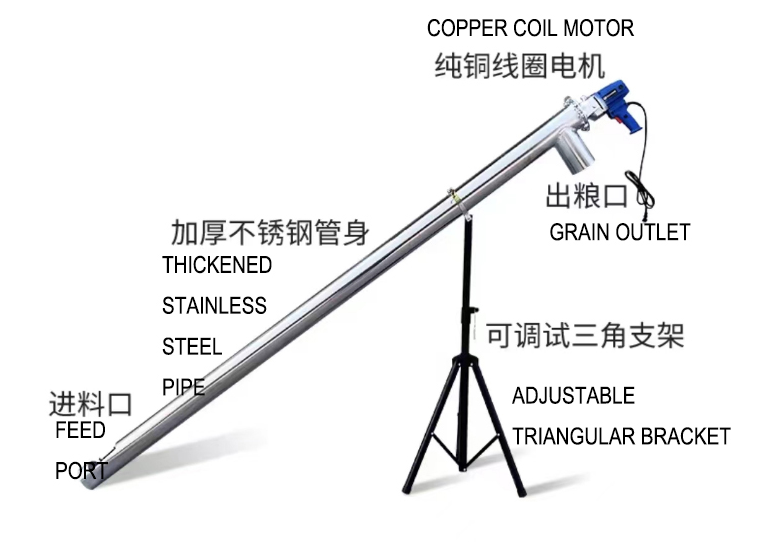

The feed stainless steel grain sucker is composed of multiple functional modules, which can achieve high-speed and stable material transportation through precise coordination.

Power system: It is the core of equipment operation. The electric model is equipped with motors of different powers, which can provide stable power according to operation requirements; the diesel model is equipped with a diesel engine and can continue to operate without an external power supply.

Conveying pipeline: It is made of all 304/316L stainless steel, with a smooth inner wall, which can effectively reduce the friction and residue of materials during transportation.

Suction and discharge device: The suction nozzle is designed to fit the material pile, which can quickly suck in granular feed such as corn and wheat; the discharge port is equipped with a special structure to ensure smooth discharge of materials and avoid blockage.

Control system: divided into basic manual control and intelligent PLC automatic control system. Manual control is simple to operate and suitable for small operations; the intelligent control system can realize one-button start and stop, conveying volume adjustment and other functions.

|

Model |

Length(m) |

Motor power(kw) |

|

RLS-102mm |

1.5-10m |

1400Kw-2800Kw |

|

RLS-114mm |

1.5-10m |

1400Kw-2800Kw |

When choosing a stainless steel feed conveyor for feed, here are some recommended selection considerations:

Material quality: Choose stainless steel material to ensure corrosion resistance, wear resistance, easy cleaning, and compliance with food hygiene standards.

Capacity requirements: Determine the required conveyor capacity based on the amount of feed used to ensure that it can meet production needs.

Power and efficiency: Consider the power and efficiency of the conveyor to ensure that it can efficiently suck and transport feed.

Ease of operation: Choose a conveyor that is easy to operate and easy to control to improve work efficiency and reduce operational complexity.

Safety: Ensure that the conveyor has safety protection devices to avoid accidental injuries.

In general, the stainless steel grain sucker for feed is an efficient, hygienic and reliable feed conveying equipment, which is widely used in animal husbandry, feed processing industry and other fields.

The price of stainless steel grain suction machine for feed is affected by many factors. From the power source, the electric model is different in price due to the different power specifications, motor power and type; the diesel-driven model has different pricing due to different engine brands and powers. In terms of materials, the cost of all 304 and 316L stainless steel is high and low, and the amount and thickness of stainless steel in the equipment also affect the final selling price. The conveying volume ranges from 5 tons to 50 tons per hour. The stronger the capacity, the higher the price. If you are interested, you can contact us for a detailed quotation sheet!

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!