Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Shaftless Screw Conveyor for Conveying Glass Fibers uses the continuous rotation of helical blades to smoothly transfer glass fibers from one location to another. The entire conveying process is gentle, effectively preventing fiber tangling, jamming, and breakage, thus preserving the original properties of the material. It supports inclined conveying, adapting to different workshop layouts without complex installation and commissioning. The inclination angle can be adjusted according to site conditions to meet various conveying needs, including horizontal and inclined conveying. Materials include carbon steel, stainless steel, and PP, catering to the conveying needs of glass fiber production at different scales.

The Shaftless Screw Conveyor for Conveying Glass Fibers is a core conveying device in the production, processing, and recycling of glass fibers, specifically addressing industry pain points such as fiber entanglement, dust generation, and breakage. Its shaftless structure completely eliminates fiber entanglement and material blockage, ensuring continuous and stable conveying.

It achieves glass fiber conveying: Utilizing continuously rotating helical blades, it smoothly transfers glass fibers from one station to another, completing the directional conveying of materials in different forms, including raw fibers, chopped fibers, and fiber powder.

It solves the problems of entanglement and breakage: Designed specifically for the characteristics of glass fibers—their easy entanglement and breakage—the shaftless structure combined with specially designed helical blades ensures a gentle and smooth conveying process, fundamentally preventing fiber entanglement and material breakage.

It flexibly adapts to conveying layouts: Supporting inclined conveying, the conveying angle can be flexibly adjusted according to the spatial layout of the workshop and the height of the production equipment, while also accommodating horizontal conveying needs without requiring large-scale modifications to the existing site.

Meets diverse operating conditions: We support non-standard customization, and can recommend suitable conveyor models based on your production needs and conveying standards to ensure the normal operation of the entire production process.

To address the material characteristics of glass fiber and its diverse conveying conditions, our factory produces multiple models of Shaftless Screw Conveyors for Conveying Glass Fibers, supporting flexible combinations to meet the needs of different glass fiber conveying scenarios.

U-shaped Shaftless Screw Conveyor: This is the most widely used basic model in glass fiber conveying scenarios. It features an open U-shaped trough with shaftless helical blades. A removable sealing cover is installed on top of the trough, allowing workers to quickly clean residual glass fiber debris and powder after shutdown, and also providing basic sealing during operation to prevent dust spillage. It is mainly used for horizontal, short-distance material transfer within glass fiber production workshops.

Double-Helix Shaftless Conveyor: This specialized model is optimized for the challenges of conveying glass fiber. It features two sets of synchronously operating shaftless helical blades, with the two helices working together to propel the material. Compared to single-helix models, it offers stronger conveying thrust and a larger conveying capacity, effectively handling agglomerates and clumps in the glass fiber. During conveying, the agitation of the double helices moderately loosens glass fiber clumps while maintaining the anti-winding advantage of the shaftless structure, preventing fiber snagging, entanglement, and jamming. It is suitable for large-scale conveying of recycled glass fiber and mixed glass fiber waste.

Tubular Shaftless Helical Conveyor: This type uses a fully enclosed circular steel tube as the conveying shell, equipped with shaftless helical blades. It completely eliminates dust leakage from the start to the end of the conveying process. The smooth interior of the circular tube, with no dead corners, combined with the shaftless blades, further reduces the probability of glass fiber adhesion and entanglement. It can not only achieve horizontal conveying but also easily complete small-angle spatial turning conveying, making it suitable for glass fiber production lines with extremely high environmental requirements and those requiring concealed conveying spaces.

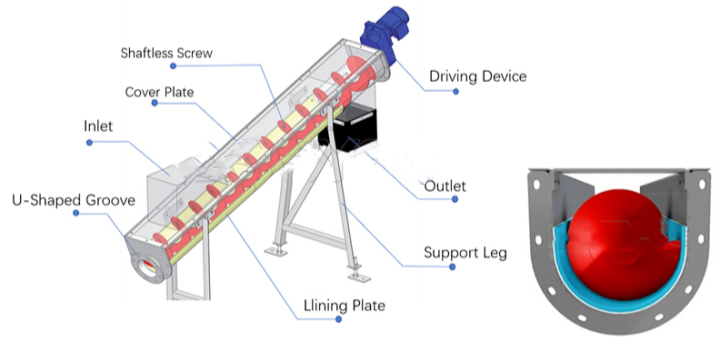

Considering the characteristics of glass fiber—its susceptibility to tangling, dust generation, and breakage—the core structure of the Shaftless Screw Conveyor for Conveying Glass Fibers can be divided into modules such as the core conveying component, drive system, housing/trough, and sealing/protection components. Each part is specifically adapted to the conveying requirements of glass fiber.

Drive Motor: A variable frequency speed-regulating motor is used, which can flexibly adjust the conveying speed according to the production rhythm of the glass fiber production line, avoiding excessive speed that would cause a large amount of glass fiber dust to fly. For the dusty environment of the glass fiber workshop, dustproof and explosion-proof motors are often used.

Trough: The housing/trough is the material conveying channel, and also serves a protective and sealing function. It mainly comes in two types: U-shaped trough and tubular trough, which can be selected according to conveying requirements.

Support Frame: The support frame is used to fix the housing and adjust the level and tilt angle of the equipment to ensure stable operation of the entire machine. Long-distance models are equipped with special shaftless hanger bearings with a sealed design to prevent glass fiber tangling.

Inlet/Outlet: The inlet is designed with a flared opening to accommodate upstream equipment such as fiberglass silos, crushers, and pulverizers, preventing material spillage. The outlet can be customized with flanges or chutes to connect to downstream processing and packaging equipment, achieving seamless material transfer.

The Shaftless Screw Conveyor for Conveying Glass Fibers relies on a continuous spiral blade without a central shaft as its core conveying component. After the glass fibers enter the conveying channel through the inlet, they are continuously pushed forward by the rotating spiral blades, moving along the casing to ultimately achieve fiber transfer. Its shaftless structure completely eliminates protruding parts such as central shafts and flanges, preventing fiberglass strand entanglement and jamming at the source. Combined with a fully sealed or semi-sealed casing, it can suppress dust leakage and smoothly convey fiberglass powder, fragments, and clumps of recycled material.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

Shaftless conveyors eliminate the central shaft, preventing glass fiber entanglement and clogging at the source. They cause less damage to materials and offer better sealing and dust suppression. While shafted screw conveyors have lower purchase costs, they are prone to shaft entanglement and jamming, making maintenance cumbersome and suitable only for non-entangled, conventional materials.

Structural Differences: Shaftless screw conveyors use continuous, flexible helical blades for direct drive, eliminating the traditional central shaft and related connecting components. They have no protruding or gapped internal structures. Shafted screw conveyors, on the other hand, rely on a central shaft for support, with blades welded or fixed to the shaft. Their structure contains multiple connection and support points prone to material accumulation.

Anti-entanglement and Anti-clogging Capabilities: Shaftless conveyors physically eliminate the possibility of entanglement, making them particularly suitable for long, easily entangled materials such as glass fiber. They can operate stably for extended periods without frequent cleaning. Shafted screw conveyors are highly susceptible to fiber entanglement and buildup at the connection between the central shaft and the blades, which not only affects efficiency but can also cause equipment jams or even motor damage.

Material Adaptability: The flexible pushing method of shaftless screw conveyors minimizes material damage and effectively reduces the risk of fiber entanglement and blockage. Shafted conveyors, due to the central shaft, are very prone to entanglement and blockage during transport.

Applicable Scenarios: Shaftless screw conveyors are a dedicated solution for entangled materials such as glass fibers and strip waste, adaptable to various layouts including horizontal, inclined, and short-distance turning. Shafted conveyors are more suitable for long-distance, heavy-duty transport of non-entangled materials such as granules and powders.

A large glass fiber manufacturer, primarily engaged in glass fiber product processing and glass fiber recycling, previously used shafted screw conveyors to transport glass fiber scraps and powders. Frequent problems arose with fiber filaments entangled in the shaft and causing blockages, affecting production continuity and requiring frequent shutdowns for cleaning. Based on the client's needs, a U-shaped shaftless screw conveyor was customized with a conveying length of 7.8 meters. All parts in contact with materials are made of 304 stainless steel, suitable for a conveying capacity of 50 cubic meters per hour. It features a removable sealing cover to address both dust prevention and convenient maintenance. After the equipment was put into use, the shaftless structure eliminated the problem of fiberglass entanglement at the source, ensuring stable and smooth operation. The fully sealed design effectively suppressed dust leakage, improving the workshop working environment while reducing fiberglass material breakage and loss, significantly reducing maintenance frequency.

The standard conveying length of a single Shaftless Screw Conveyor for Conveying Glass Fibers can reach 30 meters, meeting the long-distance horizontal and small-angle inclined conveying needs of most fiberglass production workshops and storage areas. If the conveying site has corners or a complex spatial layout, making a single straight-line device unsuitable, multiple devices can be connected in series and arranged in sections. Depending on the corner angles and workstation distribution, U-shaped, tubular, and turning shaftless screw conveyors can be flexibly combined to achieve multi-segment relay conveying, breaking through the limitations of single-machine length and straight-line conveying, and meeting the long-distance and variable-direction conveying requirements of various fiberglass production lines.

The Shaftless Screw Conveyor for Conveying Glass fibers manufactured by DaHan Machinery ranges in price from $650.00 to $3,560.00, with prices fluctuating depending on the actual equipment configuration and operating conditions. Equipment length, the material in contact with the material, and additional configurations are key factors affecting pricing. Basic short-distance models made of conventional carbon steel tend to be cheaper; long-distance customized models, those using corrosion-resistant and wear-resistant materials such as 304 stainless steel, or those equipped with frequency conversion control systems, fully sealed protection, and special hanger bearings will have higher prices. We will recommend a suitable model based on your glass fiber material form, conveyor length, workshop requirements, production capacity standards, and on-site conditions, and provide you with a detailed and transparent quotation.

The Shaftless Screw Conveyor for Conveying Glass Fibers, with its core advantages of shaftless anti-winding and sealed dust suppression, is perfectly adapted to the characteristics of glass fiber materials. A single unit can reach a maximum length of 30 meters, and multiple units can be connected in series to handle complex site layouts.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!