Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Lead Slag Screw Conveyor is primarily used for the continuous transfer of lead slag and similar high-temperature, highly abrasive, and corrosive materials.

Price: US$1200.00 - US$20,000.00/set

Diameter: 100 mm - 800 mm

Length: 2 m - 30 m

Flow Rate: 458 m³/h

Material: Carbon steel, stainless steel, composite steel plate

Inclination Angle: 0°-90°

Power: Customizable

Applicable Materials: Copper slag, zinc slag, steel slag, cement clinker, fly ash, iron ore, crushed materials, coke lumps

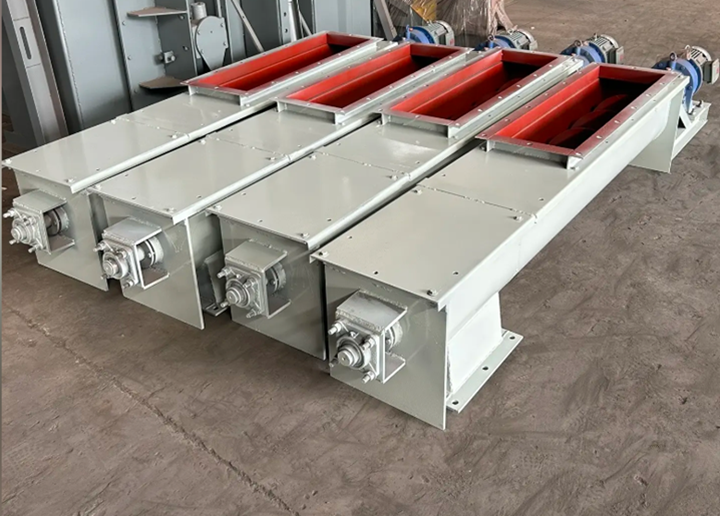

Lead Slag Screw Conveyor is a waste slag conveying equipment designed for lead smelting and recycling industries. Addressing the characteristics of lead slag—high temperature, high hardness, and corrosive media—it employs a customized structure and materials to achieve safe and stable continuous transfer. This conveyor supports horizontal, inclined, and vertical conveying, with a conveying capacity of 10-50 m³/h and a conveying length of 3-30 meters. It can flexibly connect to process nodes such as lead smelting slag outlets, slag bins, and crushing equipment. Its compact structure and small footprint make it particularly suitable for complex layouts in smelting workshops. The blades and trough can be replaced individually after wear, reducing later maintenance costs. Suitable angles, power outputs, and multiple feed and discharge points can be customized according to your production site.

The material selection for a Lead Slag Screw Conveyor requires comprehensive consideration of the physical properties of lead slag and the process environment. Our factory can provide three types of materials: alloy steel, stainless steel, and wear-resistant composite steel plates, to meet the needs of different customers.

Alloy steel: A balanced choice between high strength and wear resistance, its comprehensive mechanical properties are significantly improved through heat treatment. It is suitable for conveying dry, uniformly sized lead slag, and for medium- and low-temperature environments, avoiding softening during high-temperature annealing.

Stainless steel: Represented by 304 and 316L, it has outstanding resistance to pitting and crevice corrosion, and its smooth surface effectively reduces material adhesion. Its core applications include conveying lead slag containing acidic or alkaline components, and in food, pharmaceutical, and other fields with stringent hygiene requirements.

Wear-resistant composite steel plate: With a high-hardness alloy layer welded to the surface, its wear resistance is 5-10 times that of ordinary steel plates. It is suitable for conveying large-particle, sharp-edged lead slag, and for high-wear, high-impact environments.

With its strong sealing performance, wear and corrosion resistance, large and continuous conveying capacity, the Lead Slag Screw Conveyor can adapt to complex working conditions such as high temperatures and strong corrosion, effectively reducing material loss and environmental pollution.

High conveying efficiency: The screw conveyor can achieve continuous and uniform conveying, with a conveying capacity of tens to hundreds of tons per hour, meeting the needs of large-scale lead slag processing.

Angled conveying: The horizontal conveying angle can reach 20°, and the vertical conveying height does not exceed 6 meters, suitable for production lines with complex layouts.

Multi-point feeding/discharging: By opening multiple feeding and discharging ports on the shell, flexible distribution and collection of lead slag can be achieved.

Flexible conveying: Using a flexible screw conveyor, the conveying task can be completed in three-dimensional space, reducing the equipment footprint.

Sealed and environmentally friendly: The fully enclosed shell design effectively prevents lead slag dust from overflowing, and with the dust removal system, it can meet environmental protection requirements.

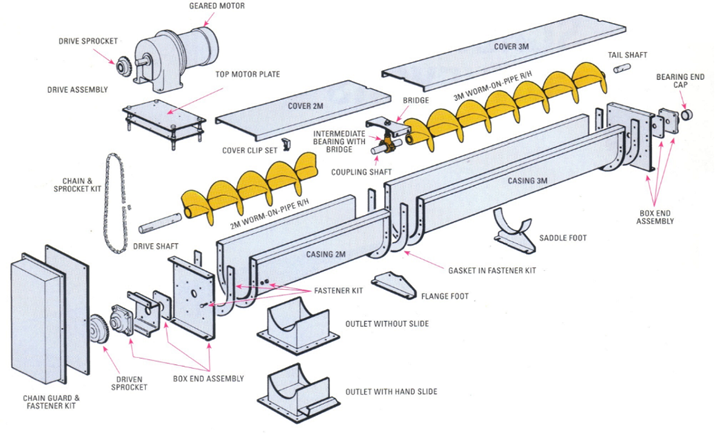

The Lead Slag Screw Conveyor mainly consists of a drive unit, screw assembly, trough assembly, sealing system, and support components. The drive unit employs an explosion-proof motor and a hardened gear reducer, providing high output torque suitable for high-load lead slag conveying. The screw assembly includes a main shaft and wear-resistant blades, with the blades designed for full-surface operation to improve conveying efficiency. The trough has a U-shaped structure with wear-resistant material lining the inner wall to reduce lead slag wear. The sealing system includes a dust cover and end cap seals to prevent dust leakage. Support components include bearing seats and brackets to ensure stable equipment operation. All structures work together, designed to meet the high-temperature and wear-resistant requirements of lead slag, achieving safe and continuous transfer.

The lead slag screw conveyor uses a motor to drive the screw shaft to rotate. The continuous propulsion of the screw blades transports materials such as lead slag from the inlet to the outlet.

Feeding Stage: Lead slag enters the conveyor housing through the inlet and accumulates at the bottom of the housing under gravity.

Propulsion Stage: The motor drives the screw shaft to rotate, generating friction between the blades and the material, causing the material to move in the direction of blade rotation. Simultaneously, the material adheres tightly to the inner wall of the shell under centrifugal force, forming a stable propulsion layer.

Discharge Stage: Under the continuous propulsion of the spiral blades, the material reaches the discharge port and is naturally discharged under gravity, completing the conveying process.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

With its compact structure, good sealing performance, and strong adaptability, the Lead Slag Screw Conveyor is widely used in lead smelting, recycling, mining, and recycling processing, especially suitable for conveying high-density, highly abrasive, or corrosive lead slag.

Smelting Workshop Slag Transfer: It can directly connect the lead smelting furnace outlet and the slag bin. The equipment can withstand temperatures below 600℃, and the fully sealed design prevents the leakage of high-temperature lead slag dust. It can continuously transport freshly produced lead slag to a temporary storage bin, avoiding the safety hazards of manual handling.

Lead slag crushing and processing: Used for material conveying between the slag bin and the crusher. The spiral blades are made of wear-resistant composite steel plates, capable of withstanding the impact and abrasion of lumpy lead slag, and evenly feeding the lead slag into the crusher to avoid blockage.

Lead slag recycling: In the sorting stage of lead slag containing metallic impurities, it conveys lead slag to magnetic separation, gravity separation, and other equipment. The equipment has a compact structure and can be flexibly arranged between sorting equipment to achieve seamless connection of multiple processes.

Lead-acid battery recycling: For lead sludge generated from battery dismantling, the conveyor uses corrosion-resistant materials to resist the corrosion of acidic substances in the lead sludge, conveying the lead sludge from the dismantling station to the purification equipment.

With its high-temperature resistance, wear resistance, and sealed structure, the Lead Slag Screw Conveyor can convey various high-temperature, high-abrasion bulk materials in addition to lead slag.

Smelting industry waste slag: Copper slag, zinc slag, steel slag, etc., suitable for continuous transfer of smelting furnace slag.

High-temperature dust: Materials such as cement clinker and fly ash require a fully sealed environment to prevent contamination and clogging. The design incorporates double seals and nitrogen protection at the shaft end to prevent dust explosions; the inner wall of the tank is polished or coated with a PTFE layer, and the spiral blades feature variable pitch for enhanced self-cleaning.

Blocky abrasive materials: Materials with high hardness and sharp edges, such as iron ore fragments and coke lumps, require both abrasion resistance and impact resistance. The design features a replaceable double-layer structure for the spiral blades, with a high-chromium cast iron outer layer and a steel inner layer; a flared buffer space at the feed inlet; and a heavy-duty reducer at the drive end to increase torque and prevent material jamming.

Corrosive waste residue: Materials such as chemical acid and alkali slag and desulfurization gypsum require long-term resistance to chemical corrosion. The design selects materials based on the degree of corrosion: 304 stainless steel for light corrosion, 316L stainless steel or duplex steel for strong corrosion, and PP/PVC plastic lining for extreme corrosion.

As a leading manufacturer with years of experience in conveying equipment, we leverage our modular design and flexible customization capabilities to tailor-make Lead Slag Screw Conveyors for clients in the metallurgical and chemical industries, successfully solving complex operating conditions such as high temperature, wear resistance, and explosion-proof requirements.

Cement Production Line Conveying: Cement needs to be conveyed from the bottom of the silo to the packaging machine over a distance of 15 meters, with an hourly output of 80 tons. The original equipment suffered from excessive dust leakage and frequent material blockage. After selecting a 500mm diameter screw conveyor and adopting thickened seamless steel pipes and felt bearings, the output reached 87.5 tons/hour, and the dust concentration was reduced to 2.5mg/m³, passing the environmental impact assessment.

Mining Waste Recycling: Lead slag containing 5-20mm particles from ore dressing needs to be conveyed to a waste treatment station over a distance of 25 meters, requiring continuous operation and high wear resistance. The customized LS500 screw conveyor features high-chromium cast iron screw blades and a wear-resistant trough, equipped with a heavy-duty reducer. Its fully enclosed structure meets mining environmental protection requirements, significantly reducing waste disposal costs.

For acid and alkali slag corrosion-resistant conveying: For conveying sulfuric acid-containing acid and alkali slag to a neutralization tank over a distance of 10 meters, high requirements are placed on corrosion resistance, sealing, and safety. A 316L stainless steel screw conveyor is selected, equipped with PTFE gaskets, an explosion-proof motor, and a ceramic coating on the trough. The explosion-proof design has passed safety inspection, and the conveying capacity reaches 15 tons/hour to meet production needs.

The Lead Slag Screw Conveyor can be customized with various configurations according to working conditions and production site requirements to improve equipment adaptability and operational stability.

Water cooling system: For high-temperature lead slag scenarios, a double-layer water-cooling jacket design is adopted. The outer layer circulates water to cool the trough and screw blades, preventing material annealing and strength reduction caused by high temperatures, ensuring long-term operation of the equipment under high-temperature conditions such as smelting slag transfer.

Explosion-proof motor: Suitable for working environments containing dust or flammable and explosive gases. The motor meets explosion-proof standards and, when paired with an explosion-proof control cabinet, effectively avoids the risk of dust explosions.

Variable frequency speed control device: Equipped with a variable frequency control cabinet, the conveying speed can be adjusted according to the feeding requirements of subsequent processes, achieving uniform conveying of lead slag and preventing material blockage or overfeeding.

Corrosion-resistant lining: When the lead slag contains acidic or alkaline corrosive components, a PTFE or polypropylene lining can be added to the inner wall of the tank, or 316L stainless steel can be used to resist chemical corrosion.

Dahan Machinery's Lead Slag Screw Conveyor starts at $1200. A specific quote needs to be customized based on your actual working conditions. The price is significantly affected by core configurations, such as material selection, whether a water cooling system or explosion-proof motor is added, conveyor length and diameter specifications, and whether additional functions such as variable frequency speed control are required, all of which will lead to price differences. We offer one-on-one selection consultation services, providing detailed quotations and configuration lists based on your material characteristics, conveying parameters, and environmental and safety requirements.

We are a source manufacturer specializing in the R&D and production of lead slag screw conveyors, possessing years of experience in manufacturing metallurgical and chemical conveying equipment and a standardized production workshop. We have customized design capabilities, and can configure water-cooling devices, wear-resistant blades, explosion-proof motors, and other components specifically tailored to the temperature, abrasion, and corrosiveness of lead slag. Core components use materials from well-known brands, ensuring equipment stability and durability. Equipped with a professional technical team, we provide one-stop service from selection consultation and solution design to commissioning and after-sales maintenance. Our products are ISO quality certified and have served many countries worldwide, solving your lead slag conveying problems.

Can screw conveyors be used with corrosive lead slag?

Yes. Targeted corrosion-resistant configurations are necessary, such as using 316L stainless steel or duplex steel for the tank and blades, with a PTFE lining on the inner wall; anti-corrosion treatment for welds; and corrosion-resistant seals. This resists the corrosive effects of acids and alkalis in lead slag, achieving sealed and stable conveying.

For large-particle, highly abrasive lead slag, how should a Lead Slag Screw Conveyor be selected?

Emphasis should be placed on wear resistance enhancement. The spiral blades should use wear-resistant composite steel plates with a high-hardness alloy outer layer to resist impact and wear; partial ceramic lining should be laid at the bottom of the tank to enhance the durability of easily worn areas. A heavy-duty reducer should also be included to prevent material jamming.

What is the horizontal conveying length of a Lead Slag Screw Conveyor?

The horizontal conveying length can reach 30 meters, meeting the material transfer needs of most workshops and sites. If a longer conveying distance is required in actual working conditions, multiple units can be connected in series. Through reasonable planning of equipment layout and connection methods, continuous and stable conveying can be achieved.

How is the high-temperature resistance of the lead slag screw conveyor?

The lead slag screw conveyor boasts excellent high-temperature resistance, with standard configurations capable of withstanding temperatures up to 600℃. The core components utilize a low-carbon steel base with an alloy weld overlay, maintaining structural strength even at high temperatures. If the conveying temperature exceeds 600℃, a double-layer water-cooling jacket can be added to prevent material annealing through circulating water cooling.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!