Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Hay Auger Conveyor uses the rotating motion of spiral blades to continuously convey materials. It can handle both dry pelletized hay and silage with a high moisture content, and can even perform complex processes such as mixing and blending.

Price: $650.00-$3,560.00/set

Conveying Capacity: 458 cubic meters/hour

Length: 30-70 meters

Speed: 13-140 rpm

Torque: 4000 N/m

Material: Carbon steel, 304 stainless steel, 316 stainless steel

Discharge ports: One or more (customizable)

Applications: Forage storage, processing, feeding, and resource utilization, covering various scales of livestock, processing, and energy production.

Hay Auger Conveyor is a modern conveying device designed specifically for agriculture and animal husbandry, suitable for horizontal or inclined conveying of various forage materials, including straw, silage, and hay. Its shaftless spiral structure completely eliminates problems with tangling and clogging, and with a conveying capacity of 5-30 tons/hour, it is an ideal choice for large-scale farms and feed processing centers.

This Hay Auger Conveyor combines practicality and flexibility, supporting a wide range of inclination angles from 0-60°, enabling stable horizontal transport or inclined lifting to meet diverse site layout requirements. Universal wheels can be added to the base for easy relocation after conveying, making it suitable for temporary forage transport scenarios. Customizable, the position and shape of the feed and discharge ports can be adjusted to suit different upstream and downstream equipment. Available materials include cost-effective carbon steel models suitable for dry forage, and corrosion-resistant, easy-to-clean stainless steel models suitable for wet or high-hygiene environments, fully meeting various forage conveying needs.

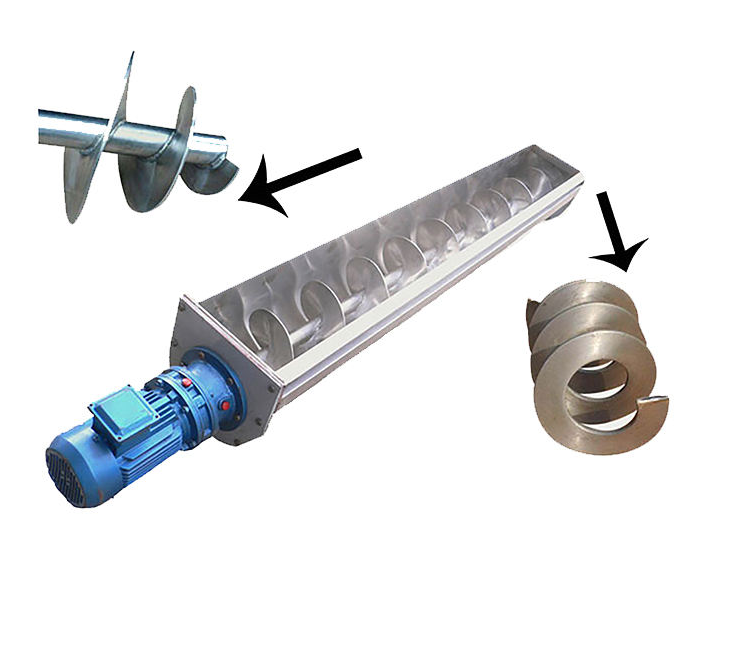

Hay auger conveyors are primarily categorized by their structural characteristics: shafted and shaftless. Each type is designed to address different hay characteristics and conveying requirements, with distinct application scenarios and functional advantages.

Shafted Auger Conveyors:Based on a core structure of "spiral blades + central shaft," the blades are fixed to a rigid central shaft. A motor drives the shaft to rotate and propel the hay. The housing is typically U-shaped or round, allowing for flexible configuration of the feed inlet and outlet. Some models feature a cleaning door for easy maintenance. They are suitable for conveying dry, loose hay without excessive fiber entanglement, such as hay meal and low-moisture silage.

Shaftless Auger Conveyors:They utilize a shaftless design with integrated, continuous spiral blades that fit snugly against the inner wall of the housing. The blades' rotation propels the hay, providing a more airtight housing. Some models utilize wear-resistant materials to reduce friction. It is designed for wet, sticky, high-fiber, or impure forage, such as fresh silage with high moisture content and forage with straw fibers. It prevents entanglement and clogging by preventing the material from wrapping around the shaft, thus reducing clogging.

The Hay Auger Conveyor features a patented shaftless, anti-entanglement design, easily handling long-fiber forage such as straw and silage. It boasts a conveying capacity of 5-50 tons/hour. Its wear-resistant material life is tripled, and its fully enclosed structure is dust- and rain-resistant, supporting multiple drive modes and intelligent control.

Moisture-proof: The fully enclosed structure prevents moisture intrusion, preventing the material from being scattered and damp during conveying.

Modular Design: The U-shaped or tubular casing is connected via flanges for quick assembly and disassembly, adapting to different deployment scenarios. Multiple units can be connected in series to form long-distance conveyor lines.

Anti-Tangle Design: The central-shaft-less spiral blades prevent entanglement of long-fiber forage, reducing failure rates. The special pitch design ensures even feed delivery without residue.

Customizable Angles: We offer hay auger conveyors designed for various scenarios and angles, and we accept non-standard customization to create the right conveying equipment for you.

The hay is confined within the conveying channel formed by the spiral blades and the casing. The hay is moved axially by the combined forces of gravity, friction, and the thrust of the spiral. This design cleverly utilizes the physical properties of the material, avoiding the excessive compression or spillage that occurs with traditional conveying equipment. It is particularly suitable for conveying fragile and easily entangled hay.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

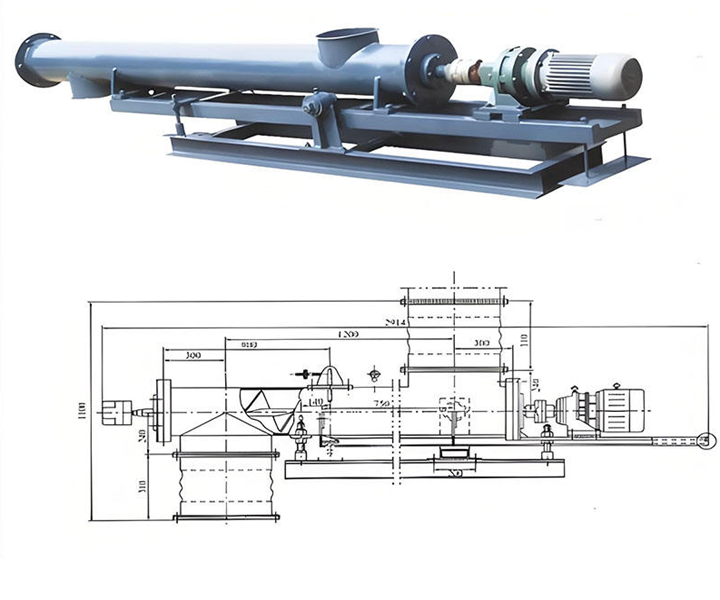

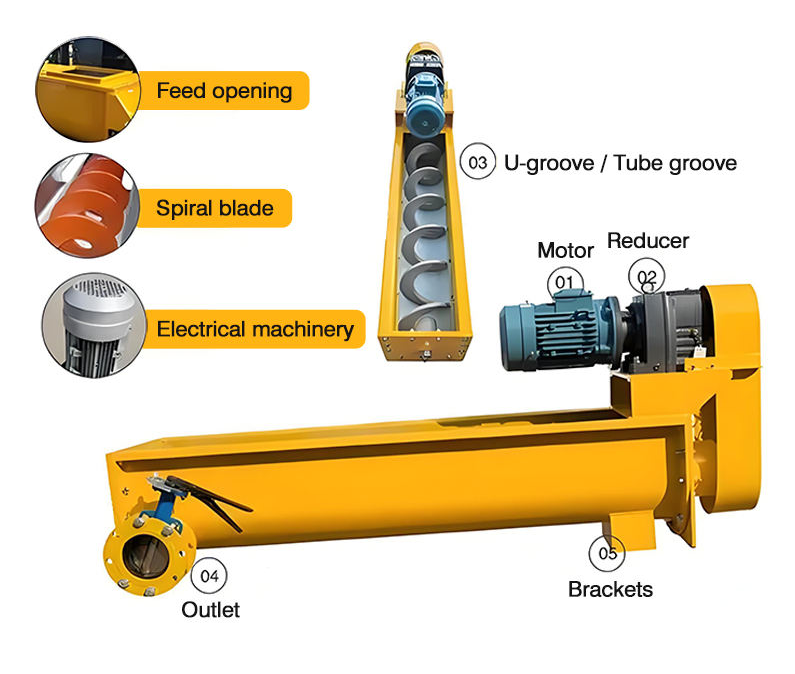

The main components of the Hay Auger Conveyor are designed around "stable conveying and adaptability to hay characteristics." The core structure includes the following key components, which work together to ensure rapid hay transport.

Drive Unit:Comprising a motor, a reducer, and a coupling. The motor provides driving force. The reducer reduces speed and increases torque, ensuring the auger blades rotate at a stable speed to prevent stalls caused by excessive hay resistance. The coupling connects the motor and auger shaft, transmitting power and dampening vibrations.

Auger Conveyor Shaft: Available in two types: shafted and shaftless. Shafted models feature a rigid central shaft with auger blades fixed to the shaft, with blade spacing optimized for loose hay. Shaftless models feature integrated, continuous auger blades without a central shaft to prevent entanglement in fibrous hay.

Casing: Most often constructed in a U-shaped or circular configuration, it is typically made of wear-resistant carbon steel or stainless steel. The U-shaped casing facilitates inspection and cleaning, while the round casing provides a more airtight seal, reducing hay spillage and dust.

Feeding and discharging device: The feeding port is mostly square or round, and can be equipped with an adjustable gate to control the feeding amount to avoid grass accumulation and blockage; the discharging port is designed according to the conveying direction, and some models are equipped with a discharge baffle to facilitate accurate docking with subsequent equipment.

The Hay Auger Conveyor's application scenarios focus on four core areas: forage storage, processing, feeding, and resource utilization, covering various scales of livestock farming, processing, and energy production.

Intra-farm feed transportation: On large cattle and sheep farms, it is used to transport hay meal, pelleted grass feed, or low-moisture silage from storage bins to feed troughs via fixed routes, enabling automated feeding.

Forage temporary storage and transfer: Connecting forage receiving areas with storage bins, for example, hay and shredded straw unloaded from transport vehicles are transported to silos or hay sheds via shafted or shaftless conveyors, completing centralized transfer prior to temporary storage.

Feed production pretreatment: In large-scale feed mills, it serves as a front-end conveyor, transporting dry, loose forage to the grinder and mixer, or low-moisture silage to the pelletizer, integrating with the production line for continuous processing. Biomass Fuel Processing: In biomass energy plants, screw conveyors are used to transport fiber-containing hay to dewatering equipment and briquetting machines for biomass pellet fuel production.

Choosing a Hay Auger Conveyor requires considering three key characteristics of hay: moisture content, fiber content, and impurity levels, and matching the appropriate model with the appropriate equipment structure.

Filter by moisture content: For dry hay, a shafted screw conveyor is recommended. Its stable structure and high conveying efficiency accommodate the loose nature of dry hay, minimizing resource waste. For moist hay, a shaftless screw conveyor is recommended. The lack of a central shaft prevents hay from clumping due to moisture, reducing the risk of blockage.

Categorize by fiber content: Low-fiber hay is best served by a shafted model. The combination of the spiral blades and central shaft ensures stable conveying and reduces entanglement. High-fiber hay requires a shaftless model. The integrated spiral blades prevent fibers from tangling around the central shaft, ensuring continuous conveying.

Judge by the impurity situation of the forage: if the forage has few impurities, both shafted and shaftless models are acceptable, and you can flexibly choose based on other characteristics; if the forage contains more impurities, shaftless models are preferred, as their casing fits tightly with the blades, and some models have wear-resistant linings on the inner walls, which can reduce the wear of the equipment on impurities and extend its service life.

Through a five-step process: defining material characteristics → determining the conveying capacity → selecting the structure type → matching the power system → customizing the functional modules, a Hay Auger Conveyor is tailored to your needs, taking into account key parameters such as feed moisture content and fiber length.

Material Analysis: Determines feed density, particle size, moisture content, and flowability. For example, when conveying alfalfa silage with a moisture content of 30%, a belt-type blade design with increased pitch is recommended.

Flow Calculation: Determine the screw diameter, pitch, and speed based on a calculation formula. Model Compatibility: When horizontal conveying distances exceed 30 meters, intermediate bearings should be installed in sections. When vertical lifting heights exceed 8 meters, a horizontal feeder is required.

Material Selection: 304 stainless steel is used for corrosive environments, while galvanized carbon steel is used for general applications.

Drive Configuration: Choose between a conventional motor and a variable frequency motor based on load characteristics. A hydraulic coupling is recommended for long-distance conveying to reduce startup shock.

We are a high-tech enterprise integrating R&D, production, and sales. We specialize in the customized production of Hay Auger Conveyors. Our product range includes U-shaped, tubular, and vertical models, and we support customization in materials such as carbon steel, stainless steel, and wear-resistant alloys. We meet the diverse needs of industries such as feed processing, biomass energy, and grain storage, with an annual production capacity of over 2,000 units. With "fast conveying and energy-saving" as our core principles, we provide a full-cycle service cycle from design to after-sales maintenance. We support customized production and provide you with professional production and conveying solutions.

The Hay Auger Conveyor, with its fast, stable, and energy-saving features, has become a core equipment in feed processing, biomass energy, and grain storage. It achieves continuous material transportation through the rotation of spiral blades, and can handle both dry granular grass and silage with high water content.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!