Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

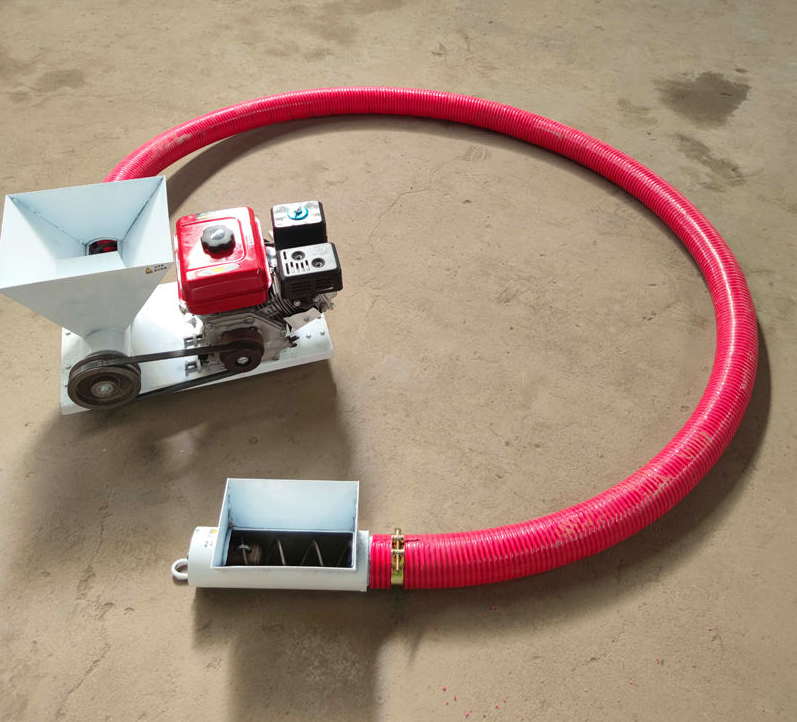

Grain Pumping Portable Grain Suction Auger Screw Conveyor Small is a lightweight grain transfer device designed for families, small farmers, and small grain enterprises. Its core features are portability and high efficiency, integrating suction and screw conveyor functions. Weighing between 5-15 kg, it comes with a carrying handle or shoulder strap, allowing for easy single-person transport. Its compact design and adjustable length, combined with a foldable form factor, make it small and space-saving.

The Grain Pumping Portable Grain Suction Auger Screw Conveyor Small combines suction and screw conveyor functions. It quickly sucks up granular grains such as wheat, corn, rice, and soybeans through a negative pressure suction port, then smoothly conveys the grain to the target container using screw blades, preventing dust and spillage. Food-grade materials are available for contact parts to ensure grain cleanliness. With a power output of only a few hundred watts, it is compatible with household 220V power supplies, consuming little electricity and operating quietly. Compared to manual labor, it can increase grain transfer efficiency by 3-5 times, reducing labor input, making it especially suitable for elderly people or families with insufficient labor.

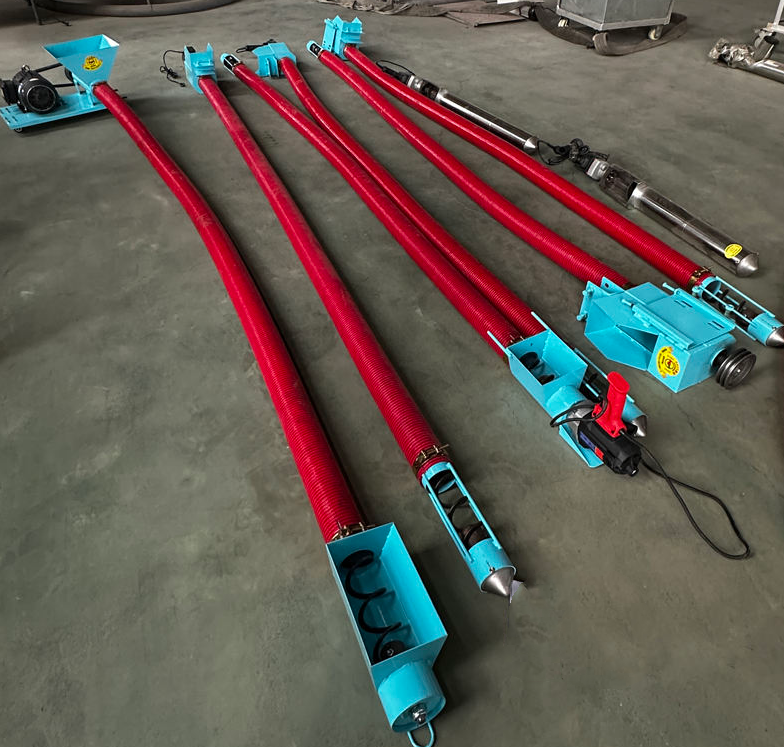

We mainly produce two types of Grain Pumping Portable Grain Suction Auger Screw Conveyor Small made of different materials to meet our customers' production needs. These are suitable for effective conveying of different materials in various scenarios.

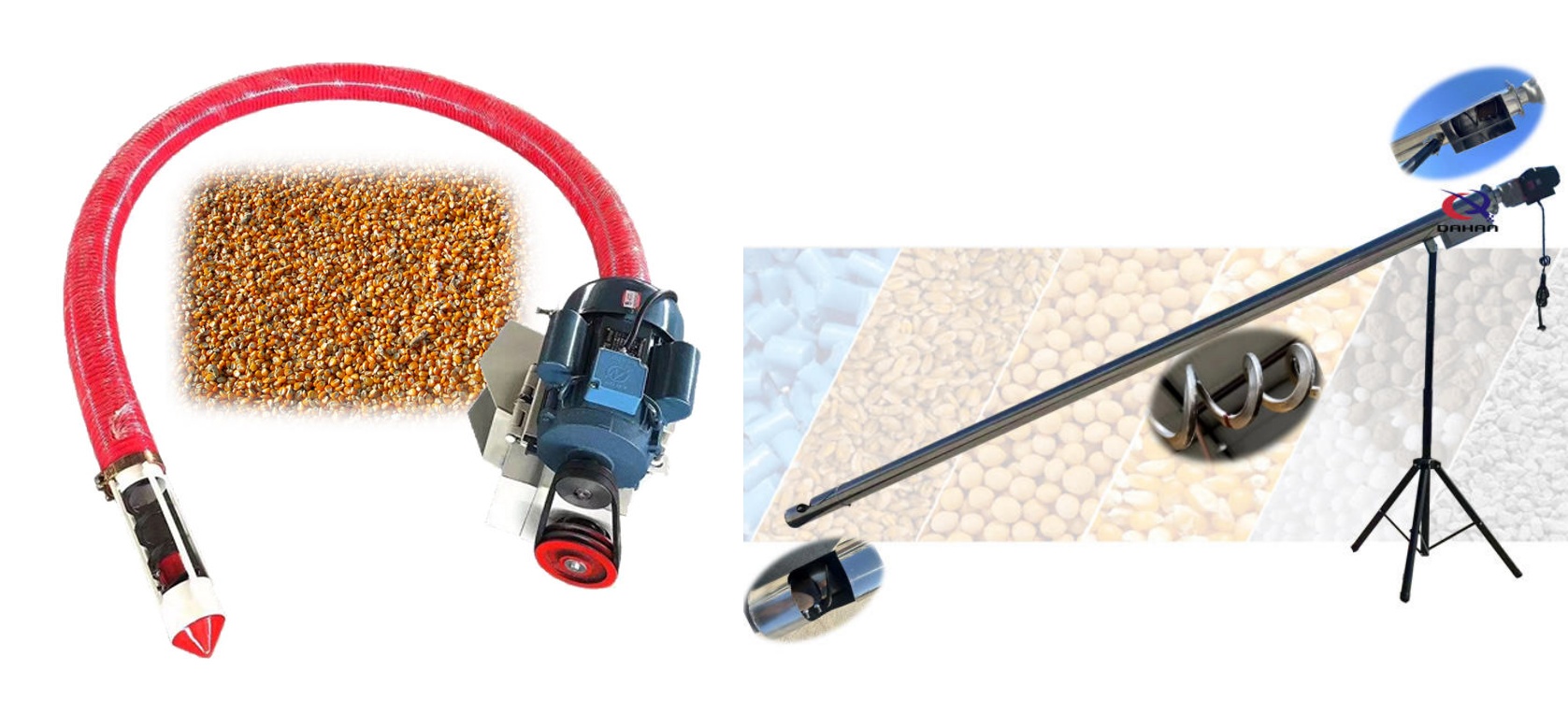

Hose Screw Conveyor: Utilizing a high-strength rubber hose conveying channel, it possesses tensile and wear-resistant properties. The standard inner diameter is 100mm, but can be customized up to 150mm. Its design emphasizes lightweight flexibility, with the entire machine weighing approximately 15-20kg. Equipped with a foldable support frame and casters, it supports single-person handling. The hose can be bent over 90°, adapting to narrow spaces such as grain silo corners and truck beds.

Stainless Steel Screw Conveyor: The entire machine is made of stainless steel, meeting food-grade standards. Its corrosion resistance far exceeds that of carbon steel, and its service life exceeds 10 years. The design features a tubular sealing structure with a 100-150mm diameter round tube to prevent dust leakage. Combined with a rainproof cover and a floating connection to prevent material jamming, it is suitable for humid and dusty environments.

The Grain Pumping Portable Grain Suction Auger Screw Conveyor Small is lightweight and easy to move, requiring no complex installation. It integrates suction and screw conveying, preventing grain spillage. It is suitable for various grain types and different conveying angles, with low energy consumption and simple operation, significantly reducing manual labor intensity.

Portability: The modular design supports quick assembly and disassembly. The head, middle, and tail sections are connected via flanges, allowing for equipment deployment within 10 minutes.

Electric/Gas/Motor Modes: Eliminating power supply limitations, it is highly suitable for remote mountainous areas or outdoor operations.

Multi-Angle Conveying: The tilting model supports multi-angle conveying from 20° to 90°. With universal joint bearings, a single unit can cover a conveying range of 30 meters horizontally and 6 meters vertically. Airtightness: The fully enclosed structure reduces dust emissions by over 90%, minimizing material spillage during transport.

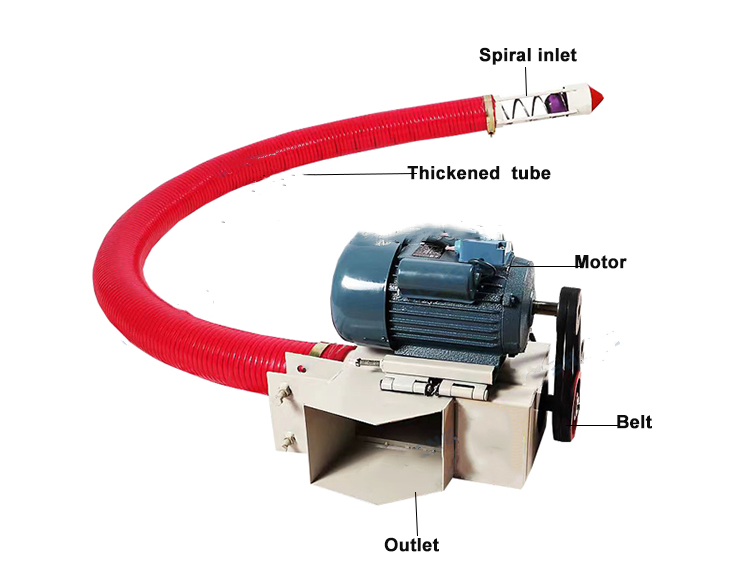

The Grain Pumping Portable Grain Suction Auger Screw Conveyor Small consists of four main parts: a power system, a conveying channel, a suction and discharge device, and a supporting moving structure. These components work together to achieve lightweight and efficient grain transfer.

Power System: Utilizing a small motor and reduction mechanism integrated design, it is compatible with most household 220V power supplies. Compact in size and lightweight, it operates stably, providing continuous rotational power to the equipment. Some models support speed adjustment to adapt to different grain types.

Conveying Channel: Constructed with high-strength flexible hose or stainless steel, it features internally manganese steel stamped spiral blades. The screw pitch matches the hose's inner diameter, ensuring even grain propulsion. The hose can be flexibly bent to adapt to narrow spaces.

Suction and discharge device: Includes a conical suction port and discharge port. The suction port is designed to reach deep into the grain pile, reducing suction resistance; the discharge port can connect to a flexible hose or directly connect to the grain storage container to prevent grain spillage.

The Grain Pumping Portable Grain Suction Auger Screw Conveyor Small achieves grain conveying through a combination of "negative pressure suction + spiral pushing." Upon startup, the power system drives the motor to rotate the reduction mechanism, which in turn rotates the spiral blades inside the conveying hose. The negative pressure generated at the suction port by the rotating blades draws the grain particles from the grain pile into the hose. The grain entering the hose is continuously pushed by the rotating spiral blades, which exert axial thrust on the grain. Simultaneously, the friction between the grain and the inner wall of the hose prevents the grain from rotating synchronously with the blades, allowing the grain to move smoothly forward along the inner wall of the hose and finally be precisely delivered to the grain storage container through the discharge port.

| Diameter | Length | Voltage | Power | Capacity | Weight |

| 100mm | 3m | 220V | 3KW | 5-6T | 43kg |

| 100mm | 4m | 220V | 3KW | 5-6T | 47kg |

| 100mm | 5m | 220V | 3KW | 5-6T | 51kg |

| 100mm | 6m | 220V | 3KW | 5-6T | 55kg |

| 100mm | 7m | 220V | 3KW | 5-6T | 62kg |

| 100mm | 8m | 220V | 3KW | 5-6T | 66kg |

| 100mm | 9m | 220V | 3KW | 5-6T | 70kg |

| 100mm | 10m | 220V | 4KW | 5-6T | 74kg |

| 100mm | 11m | 380V | 4KW | 5-6T | 82kg |

| 100mm | 12m | 380V | 4KW | 5-6T | 86kg |

| 120mm | 3m | 220V | 3KW | 7-8T | 48kg |

| 120mm | 4m | 220V | 3KW | 7-8T | 52kg |

| 120mm | 5m | 220V | 3KW | 7-8T | 56kg |

| 120mm | 6m | 220V | 3KW | 7-8T | 60kg |

| 120mm | 7m | 220V | 4KW | 7-8T | 60kg |

| 120mm | 8m | 220V | 4KW | 7-8T | 71kg |

| 120mm | 9m | 220V | 4KW | 7-8T | 75kg |

| 120mm | 10m | 220V | 4KW | 7-8T | 79kg |

| 120mm | 11m | 380V | 4KW | 7-8T | 89kg |

| 120mm | 12m | 220V | 4KW | 7-8T | 93kg |

| 100mm | 20m | 380V | 7.5KW | 5-6T | 150kg |

| 100mm | 25m | 380V | 7.5KW | 5-6T | 170kg |

| 120mm | 20m | 380V | 7.5KW | 6-7T | 180kg |

| 120mm | 22m | 380V | 7.5KW | 6-7T | 200kg |

Application scenarios for the Grain Pumping Portable Grain Suction Auger Screw Conveyor Small include: emptying grain storage in households, replenishing rice containers, bagging grain after drying in the fields for small farmers, and cleaning up leftover grain in corners of grain warehouses. It is suitable for transporting various types of granular grains.

Field Applications: Works with harvesters to enable immediate loading of crops such as wheat and rice, reducing losses during the drying process.

Family Farms: Used for short-distance transportation of feed ingredients (such as corn and soybean meal) from warehouses to farms.

Flour Mills: Transports cleaned wheat grains to the mill, completing preliminary mixing during the transport process.

Feed Mills: Uses a twin-screw conveyor to transport multiple raw materials to the mixer in proportion, with an accuracy error of ≤1%.

Port Terminals: Vertical screw conveyors enable rapid unloading of grain from ship holds to warehouses, with a daily processing capacity exceeding 2000 tons.

Cold Chain Logistics: Stainless steel models are designed for low-temperature environments, transporting frozen corn, soybeans, and other food items.

The price of DaHan Machinery's Portable Grain Suction Auger Screw Conveyor Small starts from $80, with a tiered price range influenced by equipment configuration and features. Basic models typically have manually adjustable supports and smaller pipe diameters, suitable for small-scale grain transport by households. Mid-range models feature foldable supports, casters, and speed adjustment, with pipe diameters of 80-100mm, offering superior conveying efficiency and portability. High-end models use food-grade contact materials and thickened screw blades, with some models supporting customized lengths, suitable for frequent use by small farmers or small grain stores. Price differences mainly stem from materials, conveying length, motor power, and additional features, offering excellent overall value and meeting the needs of different users' budgets and usage scenarios.

What are the characteristics of the conveyed material? Is the flow rate good or poor? Is it wet or dry?

Suitable for granular and powdery materials, such as wheat, corn, and starch. High-moisture materials that are prone to sticking and clogging are not recommended. Flow rate is adapted to demand; basic models offer 1-3 tons per hour, while mid-range models offer 3-5 tons per hour, meeting the needs of households/small farmers.

Bulk density of conveyed material = ? kg/m³

The suitable bulk density for grain materials is mostly 600-800 kg/m³. For example, wheat is approximately 750-800 kg/m³, corn 650-700 kg/m³, and rice 550-600 kg/m³ (dry state). The equipment is designed to accommodate this density range to ensure minimal clogging during conveying.

Conveying capacity = ? m³/h

This needs to be determined based on your conveying method and the material being conveyed. Generally, the maximum conveying capacity for horizontal conveyors can reach 20 tons per hour.

Transport Length = ?M

Our flexible hose type single unit can reach a maximum length of 30 meters. For longer distances, it needs to be used in series. The stainless steel type can reach a length of 4 meters.

Conveyor Can Be Horizontal, Inclined, or Vertical

Our equipment supports three installation methods: horizontal, inclined, and vertical. Horizontal installation is suitable for short-distance planar transport. Inclined installation allows the angle to be adjusted via brackets. Vertical installation can reach 90°, but the height is limited to 6 meters.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!