Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

When traditional shaft screw conveyors convey viscous and easily wound materials, equipment failures often occur due to materials blocking the central shaft, affecting production efficiency. The food-grade shaftless screw conveyor innovatively adopts a center-free design, and directly pushes materials with integral steel spiral blades, completely avoiding this problem.

Type: Single-axial-free/Double-axial-free

Diameter: 150 - 500 mm

Installation inclination: 0-15° or 0-30°

Length: 0-20 meters or 0-30 meters

Production: 0.8 tons/hour - 45 tons/hour

Power: 0.55 kW - 5.5 kW Speed: 29 rpm

Structural material: 304/316 Stainless steel

Inclination: <40 degrees

Application: Can handle viscous, high moisture content, humid materials, meat/fish/fruit and vegetable processing.

Food grade shaftless screw conveyor is a shaftless screw conveyor specially designed for the food industry. It is made of 304/316L stainless steel as the main material. The shaftless screw structure avoids the center shaft winding. It is equipped with variable pitch blades to efficiently push flour, jam and other materials. The fully sealed tube/U-shaped groove body prevents dust spillage and foreign matter invasion. The standard CIP online cleaning system is equipped with a full equipment cleaning in 30 minutes. It is suitable for baking raw materials transportation, dairy product transportation, candy pellet sorting and other scenarios.

The food-grade shaftless screw conveyor is made of stainless steel, with a shaftless design that is anti-winding, and the surface is electrolytic polished and easy to clean. The main features are as follows.

Shaftless clean structure: remove the central shaft design to avoid material accumulation at the shaft end, and integrate welding of spiral blades and drive shafts to reduce material residue by more than 90%.

Food-grade material system: The main body is 304/316L stainless steel, the grooves and blades of the contact materials are electrolytically polished, and the sealing ring is made of food-grade silicone rubber to prevent heavy metal migration and plasticizer pollution;

CIP online cleaning system: equipped with a high-pressure rotary nozzle, complete the full surface of the equipment in 30 minutes, and the cleaning water recovery rate reaches 85%, meeting the hygiene needs of multiple shifts per day.

Explosion-proof and anti-static design: For dust-prone scenarios such as flour and powdered sugar, ATEX certified explosion-proof motors and electrostatic grounding devices are configured.

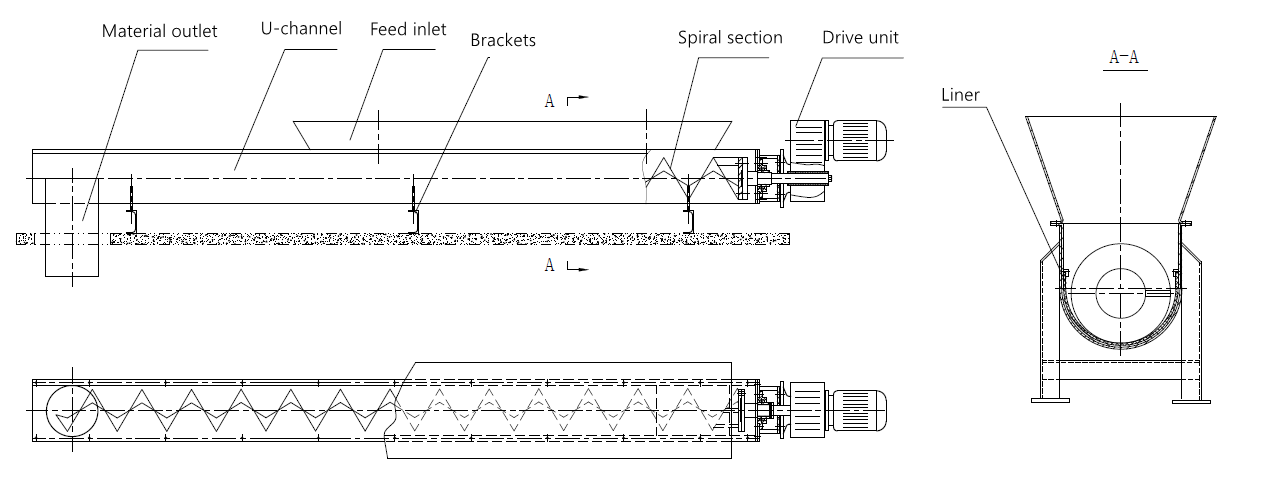

Food-grade shaftless screw conveyors realize material transportation through the rotation of shaftless screw blades in U-shaped grooves or tube channels. When the motor drives the spiral blades to rotate, the thrust of the spiral surface is used to move the flour, candy particles and other materials along the axial direction of the groove body. The axle-free design avoids contact between the central axis and the material, reducing the risk of winding and residual.

The main body of the food-grade shaftless screw conveyor is made of 304/316L stainless steel, which meets hygiene standards and ensures food hygiene and safety in all aspects.

304 stainless steel: is the basic material of the food industry, with excellent corrosion resistance and molding. After the surface is mirror polished, it fully complies with the food contact material standards. Its chromium nickel content can tolerate weak acid and alkali environments. If it is vegetable juice, dairy products, flour, etc., it is extremely cost-effective and suitable for conventional food delivery.

316 stainless steel: By adding 2%-3% molybdenum, it significantly improves its ability to resist chloride ion corrosion, and has become the first choice for seafood processing, fermented food, high-salt sauce and other scenarios. Its ultra-low carbon 316L variant can also avoid intergranular corrosion in the welding area, which is suitable for working conditions that require frequent disassembly and cleaning.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

Our shaftless screw conveyors can be used at different processing stages in food processing scenarios, and can perfectly match other equipment to complete the production process.

Raw material pretreatment section: In the raw material pretreatment process, the transportation of grains and powders is crucial. The tube-type sealed shaftless screw conveyor is an ideal equipment, with a flexibly selected pipe diameter of φ150 - 400mm. The equipment adopts a fully sealed circular tube structure, which can effectively prevent dust spills such as flour and cocoa powder.

Food processing section: In the processing section, the transportation of viscous materials is a major challenge. U-shaped shaftless screw conveyor stands out with its unique design. The blades adopt a variable pitch design, with a front end pitch of 250mm and a rear end of 200mm. For viscous materials such as jam and cream, the viscosity of the material is reduced by pushing.

Finished product packaging section: The finished product packaging section has extremely high hygiene requirements, and the equipment selected in this section has been upgraded in terms of material. The surface of the spiral blade is plated with hard chrome, and the groove body is polished with 316L stainless steel mirror. This design is suitable for the transportation of finished materials such as candy granules and nut crushed materials. The chrome plating layer can prevent the blade from wear and produce metal debris. The mirror surface avoids material adhesion, and can meet the strict hygiene requirements of exported food.

The exclusive food-grade functional module contains a foreign object detection system, which can quickly identify foreign objects such as iron filings; it is sterile isolation design to ensure a clean transportation environment.

Anti-foreign object detection system: built-in metal sensor, which can automatically shut down and alarm when foreign objects such as iron chips, screws and other foreign objects are mixed into the conveying material.

Sterile isolation design: The shaft end adopts dual-end mechanical seal (food-grade ceramic + fluoroelastomer), combined with a nitrogen purge device, to achieve clean room standards in dairy product delivery.

Quick disassembly and assembly structure: The groove body and the blade are connected in a clamp type, and the main components can be disassembled within 10 minutes, which is convenient for manual deep cleaning.

In the field of food processing, many companies use food-grade shaftless screw conveyors to achieve production upgrades. The following is our customer usage.

Baking industry: Large flour processing plants face the dual challenges of conveying efficiency and hygiene standards. In order to improve the overall production capacity, the factory introduced 3 φ400mm food-grade shaftless screw conveyors to realize the sealed conveying of materials and effectively avoid dust spillage and cross-contamination. With this advanced conveying system, the factory's annual conveying volume is as high as 50,000 tons, greatly meeting the needs of large-scale production.

Beverage production: The juice processing plant uses tube stainless steel models to transport pulp residues. The equipment uses 316L high-quality material, with excellent anti-fruit acid corrosion ability, can operate stably in an acidic environment for a long time, ensuring the reliability of the conveying process. In addition, the equipment is equipped with an advanced CIP system, which can automatically complete cleaning work every day, effectively avoiding the growth of microorganisms.

Meat processing: The slaughterhouse uses a U-shaped shaftless screw conveyor in the minced meat conveyor. The blade edges of the equipment have been carefully rounded to completely eliminate sanitary dead corners and prevent bacteria from growing. At the same time, the equipment can be combined with the high-temperature steam sterilization process and continuously sterilize at a high temperature of 121℃ for 30 minutes.

The price of food-grade shaftless screw conveyor starts from $2,500 (basic 304 stainless steel model). The specific cost fluctuates according to the material and function. The price difference mainly comes from the material grade (304 resistant to conventional food, 316L resistant to high salt/acidity), sanitary configuration (CIP cleaning system + $1,500) and intelligent control. The price will also increase for every 1 meter of size, and the cost will increase by 30%-40% for every 100mm expansion of diameter. It is recommended to choose 304 models for dairy products/baking, and 316L models for the aquatic products/fermentation industry, which will save maintenance costs in the long term.

As a professional manufacturer of food-grade shaftless screw conveyors, Dahan Machinery has been focusing on providing high-standard conveyor equipment for the food industry for many years. The product is made of 316L/304 stainless steel, ensuring that the material residue rate is less than 0.1%, perfectly meeting the strict hygiene requirements of dairy, meat products, condiments and other industries. We provide customized services in the diameter range of 113-500mm, equipped with a quick disassembly structure and a CIP cleaning system, and the cleaning time takes only 10 minutes. With modular design, intelligent control system and customized service design, we serve multi-plus enterprises. If you also need delivery, please contact us at any time to get the latest and best models and price lists!

With its advantages of shaftless design, food-grade materials, efficient transportation, flexible installation and simplified maintenance, food-grade screw conveyors have become an ideal choice for material transportation in food processing, pharmaceuticals, chemicals and other industries. It not only improves production efficiency and ensures product quality, but also reduces operation and maintenance costs, creating significant economic and social benefits for the enterprise.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!