Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

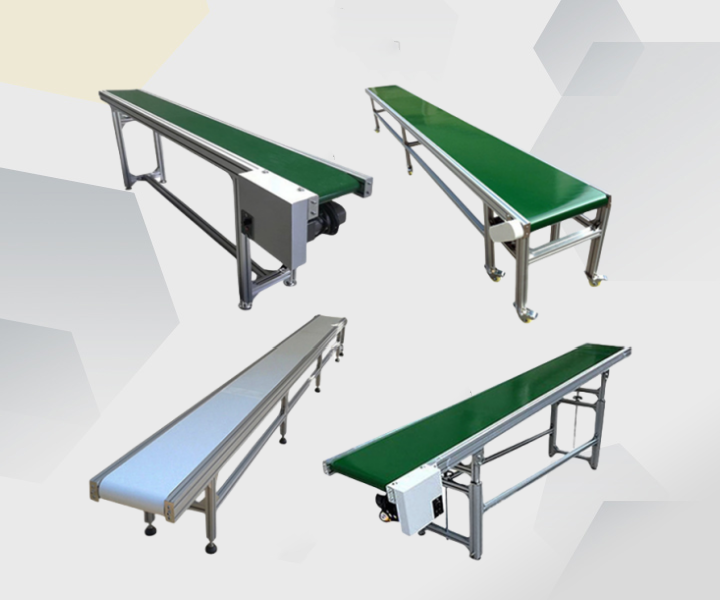

Flat Belt Portable Conveyor is a mobile conveying equipment designed for short-distance, light and medium-duty material handling.

Dimensions (L*W*H): Customized size

Features: Durable, easy to move, hygienic

Speed: 1-20 m/min Variable speed

Length: 3-30 m (customizable)

Belt width: 400/500/600/800/1000/1200 mm

Belt material: rubber belt, PVC belt, PU belt silicone belt

Applicable industries: hotels, clothing stores, manufacturing plants, food and beverage plants, farms, restaurants, homes, retail, food stores, and catering stores.

Flat Belt Portable Conveyor is a material handling equipment designed for rapid deployment. It adopts a high-strength lightweight body and foldable design. It is light in weight, easy to move, and can be easily pushed by one person. Equipped with universal casters and brake system, it can quickly transfer workstations to meet the needs of multiple scenarios such as warehousing logistics, construction sites, and agricultural production. The conveyor belt width is optional from 200 to 800mm, and it supports a variety of belt materials such as rubber, PVC, and PU to meet the standards of different industries such as food, chemicals, and express delivery.

Five core advantages of Flat Belt Portable Conveyor are widely used in multiple scenarios such as logistics/construction/agriculture, significantly improving handling efficiency!

Plug and play: No need to install a foundation, it can be operated after unfolding, which is suitable for temporary warehouse replenishment, truck loading and unloading, etc.

Convenient to move: It can be pushed by one person, and can be directly placed in a truck compartment or a small warehouse after folding. It saves more than 60% of storage space compared to traditional conveyors, and multiple units can be used in series to extend the conveying distance.

Low energy consumption and high efficiency: The motor power is 0.5-3kW, and 10-50 tons of materials (such as parcels and boxed goods) can be transported per hour.

Labor saving: Compared with manual handling, the efficiency is increased by 3-8 times, and the labor cost is reduced by more than 50%.

Multifunctional adaptation: Optional hydraulic lifting (adjusting height 0.5-1.5m), electronic weighing or scanning terminal to achieve intelligent operation.

Customizable: The length, material, bandwidth, and roller can be designed according to the production needs of customers.

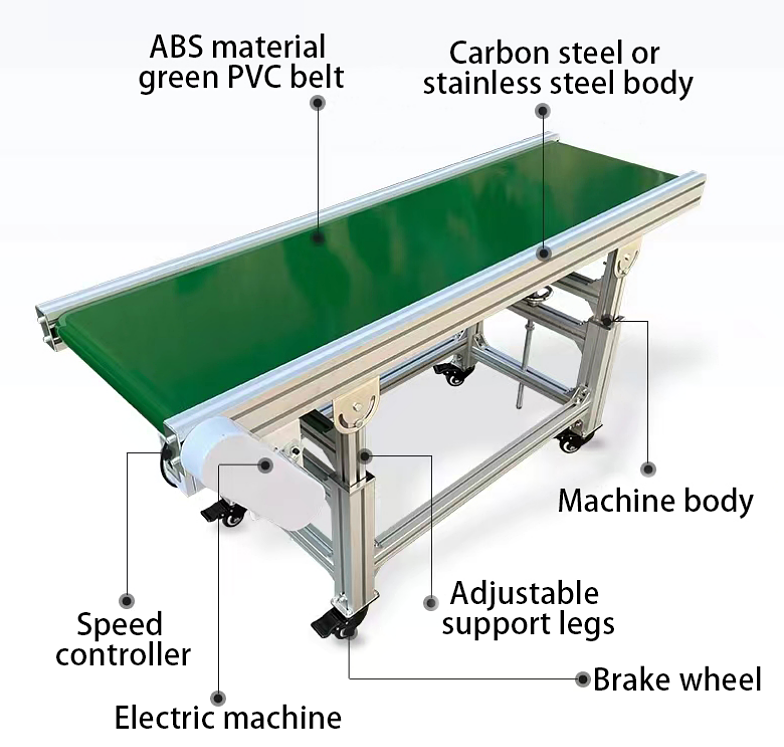

Adopting high-strength aluminum alloy/steel frame, equipped with foldable rack and universal casters, it can achieve rapid mobile deployment. Its main structure has the following points.

Light rack: using aluminum alloy or high-strength steel pipe, light weight (usually 50-200kg) and corrosion-resistant.

Conveyor belt: rubber/PVC material, optional width 300-800mm, anti-slip grooves or ribs can be added on the surface.

Folding design: Some models support folding or segmented disassembly of the fuselage for easy transportation and storage (the length can be reduced to less than 2m after folding).

Drive mode: Electric roller or motor + gearbox drive, voltage can be selected 220V/380V or battery power supply.

Speed regulation function: Standard stepless speed change (transmission speed 0.3-2m/s adjustable), adapting to different working rhythms.

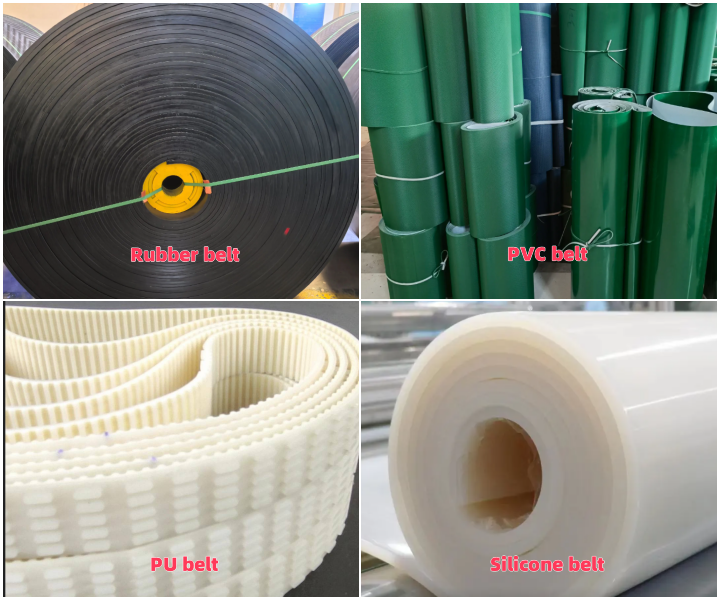

Horizontal belt portable conveyor can be made of rubber, PVC, PU and silicone, and different characteristics are suitable for construction, food, electronics and other industries.

Rubber belt: Ordinary rubber belt has wear resistance and tensile resistance, and patterns can be added to enhance anti-slip properties. It is suitable for conveying general industrial materials such as building materials and ores.

PVC belt: Ordinary PVC belt is economical, lightweight and corrosion-resistant, suitable for conveying light packaging boxes and electronic products, with a thickness of 1-5mm. The surface resistance of anti-static PVC belt is 10^6-10^9Ω, which can meet the special needs of electronic components and flammable dust environments.

PU belt: PU belt is known for its high elasticity and oil resistance, and its operating noise is less than 60dB, ensuring a quiet working environment. It is not only suitable for scenes with high requirements for cleanliness and stability, such as precision instruments and cosmetic packaging, but also can maintain flexibility and strong adaptability in low-temperature environments of -30℃.

Silicone belt: Silicone belt has excellent high temperature resistance and can work stably in the range of -60℃~250℃. At the same time, it has excellent antibacterial properties and is widely used in processes with strict requirements on hygiene and temperature, such as baked food and pharmaceutical sterilization.

The core power of Flat Belt Portable Conveyor comes from friction drive. The motor drives the drive roller to rotate through the reducer, and the static friction between the roller and the conveyor belt drives the conveyor belt to circulate, and the material moves synchronously on the conveyor belt by friction. Its technical highlight lies in the modular design: the conveyor body consists of multiple standard segments, which are spliced by quick connection devices. The length of a single segment is usually 2-3 meters, and the conveying length can be flexibly adjusted according to site requirements.

Due to its light mobility and rapid deployment, this equipment is widely used in fields that require short-distance flexible transportation, including warehouse cargo loading and unloading, construction site sand and gravel transfer, farm grain loading, express parcel sorting, production line material connection, etc.

Warehousing and logistics: In the cargo loading and unloading and express sorting links, the horizontal belt portable conveyor has become a key tool to improve efficiency. When loading and unloading trucks, it can quickly connect vehicles and sorting areas, efficiently transport parcels and goods to designated locations, replace traditional manual handling, and significantly reduce labor intensity.

Agricultural production: In the grain loading, fertilizer and feed turnover scenarios, the horizontal belt portable conveyor shows strong practicality. When transporting grain, it can avoid the spillage of bulk materials and reduce losses. At the same time, it can quickly complete the loading task, save a lot of time, and provide strong support for the efficient operation of agricultural production.

Building decoration: For the short-distance transportation problem of heavy objects such as sand, gravel, and building materials, the horizontal belt portable conveyor is an ideal solution. It replaces the traditional trolley, eliminating the need for workers to carry repeatedly, effectively reducing labor intensity; at the same time, the characteristics of continuous transportation make the transportation of building materials more efficient and speed up the construction progress, especially in narrow or complex construction environments, its flexible mobility advantage is more prominent.

Factory workshop: In terms of material transmission on the production line, the horizontal belt portable conveyor adapts to various process changes with its flexibility. It can seamlessly connect different production lines to achieve fast and accurate material transmission.

Supermarket distribution: In the scenes of cold chain cargo loading and unloading and shelf replenishment, the horizontal belt portable conveyor plays an important role in ensuring the safety of goods. When loading and unloading cold chain goods, the smooth transportation process can avoid collision and extrusion of goods and protect the integrity of the product packaging.

|

Comparison Dimension |

Horizontal Belt Portable Conveyor |

Fixed Belt Conveyor |

|

Structural Features |

Lightweight materials (e.g., aluminum alloy) for the frame, compact structure; some can be folded or disassembled; equipped with universal wheels or crawlers for easy mobility. |

Heavy frame, mostly fixed installation; no mobility device or difficult to move. |

|

Mobility |

Can be easily pushed by one or more persons, quickly transferred between different work points to adapt to multi-site needs. |

Requires professional installation teams for disassembly, transportation, and reinstallation; high mobility cost and time-consuming. |

|

Application Scenarios |

Suitable for short-distance and flexible material handling, such as temporary sorting in e-commerce warehouses, temporary connection of workshop processes, and material transfer in small construction sites. |

Suitable for fixed routes, long-distance, and large-batch material transportation. |

|

Conveying Efficiency |

Stable conveying speed, continuous operation, large conveying capacity per unit time; conveying speed can be adjusted as needed. |

Large conveying capacity but poor flexibility. |

|

Maintenance Cost |

Modular design, easy replacement of vulnerable parts (e.g., conveyor belts, rollers); simple structure, few failure points, low maintenance costs. |

Complex structure, difficult maintenance, high maintenance costs. |

|

Maintenance Cost |

Can quickly adjust the conveying position and direction to adapt to changes in different work processes; can meet diversified material handling needs by adjusting the conveyor belt width and speed. |

Difficult to adapt to changes in work processes; reinstallation is required to change the route. |

Select the belt material according to the material type, determine the fuselage length according to the operating distance, and add weighing or lifting functions for special scenes.

Particle size and shape: If the conveyed material particles are large (such as block building materials with a diameter of more than 5cm), it is necessary to select equipment with a larger belt width and a wide spiral pitch to prevent material blockage; for materials with irregular shapes or sharp corners, the wear resistance of the conveyor belt should be considered, and thickened rubber materials or conveyor belts with protective layers can be selected.

Humidity and viscosity: Materials with high humidity or strong viscosity are easy to adhere to the conveyor belt. Conveyor belts with smooth surfaces and low friction, such as PVC materials, should be preferred, and the inclination angle of the conveyor should be appropriately increased (no more than 15°) to assist the material to slide down smoothly and avoid material accumulation.

Corrosiveness: When conveying corrosive materials, the contact parts of the entire conveyor, including the frame, conveyor belt, roller, etc., must be made of corrosion-resistant stainless steel, such as 316L stainless steel, to ensure the service life of the equipment and prevent safety hazards and economic losses caused by corrosion damage.

Dahan Machinery has been focusing on the research and development and production of high-quality light conveying equipment for many years. It has a modern production base technology production line, and its products have passed ISO9001 and CE certification. The company provides portable conveyors with a bandwidth of 200-800mm. In addition, it can support customized production. It adopts a high-strength aluminum alloy frame, equipped with universal casters and folding design. It has the characteristics of lightness, flexibility, strong load-bearing capacity, etc., and can provide a variety of belt materials such as rubber, PVC, PU, and customized configurations such as motor speed regulation and hydraulic lifting according to customer needs. With excellent product quality and a 24-hour quick response after-sales service system, the products are exported to many countries around the world and are an ideal partner for efficient material transportation in various industries.

Flat Belt Portable Conveyor takes "lightness, flexibility, and high speed" as its core, perfectly solving the pain points of temporary material handling. Whether it is the sorting pressure in the peak season of e-commerce or the sudden transfer of building materials on the construction site, it can respond to demand quickly and significantly reduce manpower dependence. When selecting, it is necessary to focus on material characteristics, movement frequency and extended functions to match actual operation needs.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!