Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Fish Feed Screw Conveyor is an automated conveying equipment specifically designed for granular and powdered fish feed. Its enclosed structure prevents moisture, dust, and contamination of the feed. It supports multi-angle installation, including horizontal and inclined configurations, and is suitable for various scenarios from aquaculture farms to feed mills.

Price: $450.00 - $3,200.00/set

Diameter: 100 mm - 1250 mm

Hopper Capacity: 100-300 kg

Feeding Capacity: 1000 kg/hour

Feeding Height: 2-12 meters

Material: Carbon steel, stainless steel, plastic

Layout: Horizontal, vertical, inclined

Applicable Materials: Flour, coffee powder, corn flour, concrete, cement, coal powder, ash, grains, etc.

Fish Feed Screw Conveyor is a high-speed, flexible mechanized conveying device used in aquaculture and feed processing. Its core principle is to continuously push granular, powdered, or highly moist and sticky fish feed along a fixed pipeline using rotating helical blades, achieving automated transportation from the storage silo to the feeding point. Compared to traditional manual handling or pneumatic conveying, this equipment offers advantages such as stable conveying, low loss, and strong adaptability, making it particularly suitable for the material flow needs of large-scale farms, feed processing plants, and automated aquaculture systems.

The biggest highlight of our Fish Feed Screw Conveyor is its support for non-standard customization. Customers can choose materials such as carbon steel, stainless steel, or food-grade plastic according to their actual needs, and match the type of helix, including shafted, shaftless, or flexible hose helices. They can also adjust the helix diameter, length, and conveying angle (0°-90° full coverage). Combined with variable frequency speed control technology, the equipment can achieve a conveying capacity adjustment of 3-30 tons per hour, precisely matching the daily feeding needs of farms of different sizes, providing a reliable solution for improving feed utilization and reducing labor costs.

Fish feed screw conveyors can be categorized into various types based on their structure, layout, and function, precisely matching different production scenarios. Each model can be customized to meet different production needs and process requirements.

Shafted Screw Conveyor: Its core structure is a combination of a rigid screw shaft and screw blades. The screw shaft is fixed inside the housing by bearings. During rotation, the screw blades push the material axially, achieving horizontal, inclined, or vertical conveying. This type of conveyor is suitable for conveying dry, free-flowing granular or powdered fish feed.

Shaftless Screw Conveyor:By eliminating the central shaft design, it uses integral steel screw blades to directly push the material, significantly improving anti-tangling and conveying efficiency. This type is particularly suitable for conveying fish feed with high oil content, easy adhesion, or a ribbon-like or easily tangled texture, such as wet fish bait and filter press cake.

Hose Screw Conveyor:This type combines the efficiency of traditional screw conveyors with the flexibility of hose conveyors. It uses a flexible hose as the conveying channel, with internal screw blades propelling the material. This type is particularly suitable for conveying scenarios requiring flexible layout or frequent movement, such as distributing feed from storage silos to multiple aquaculture ponds, or rapid loading during truck transport. It can adapt to conveying fish feed with varying moisture content and particle size, and its small bending radius allows for complex path conveying in three-dimensional space.

As a core piece of equipment in aquaculture and feed processing, the Fish Feed Screw Conveyor demonstrates significant advantages in efficiency, adaptability, hygiene, and cost due to its structural characteristics and functional design.

Multi-material compatibility: Supports materials such as carbon steel, stainless steel, and food-grade plastics, and can convey dry pellets (such as fish food), powdered feed (such as fishmeal), and highly moist and viscous materials (such as wet bait), avoiding clogging or residue caused by material characteristics.

Full-angle coverage: By adjusting the screw parameters and drive power, it can achieve horizontal, inclined, and vertical conveying from 0° to 90°, meeting the three-dimensional feeding needs of aquaculture farms from the ground to upper-level ponds.

Continuous Operation: The spiral blades continuously propel materials without interruption, with a single unit conveying capacity of 3-30 tons/hour, suitable for small and medium-sized processing lines and large-scale aquaculture farms.

Modular Structural Design: Available in shafted, shaftless, and flexible hose spiral types, allowing customers to choose the model based on space layout, conveying distance, and feeding accuracy.

Personalized Functional Expansion: Supports configurations such as variable frequency speed control, automatic cleaning, and anti-backflow baffles. For example, the conveying speed can be controlled via a variable frequency motor to adapt to the feeding frequency of fish at different growth stages; or a cleaning device can be added to reduce the risk of mold growth caused by feed residue.

Customized Size and Angle: The spiral diameter, length, and conveying angle can all be adjusted as needed, such as customizing vertical lifting models for high-rise aquaculture ponds, or designing multi-segment inclined combined conveyor lines for complex terrain areas.

The core principle of the Fish Feed Screw Conveyor is based on the rotational motion of a spiral blade. When the drive unit rotates the spiral shaft, the spiral blades fixed on the shaft push the material forward from the feed inlet along the closed channel. During the conveying process, the material is subjected to both friction from the spiral surface and axial thrust, forming a continuous spiral trajectory, and finally discharged from the outlet.

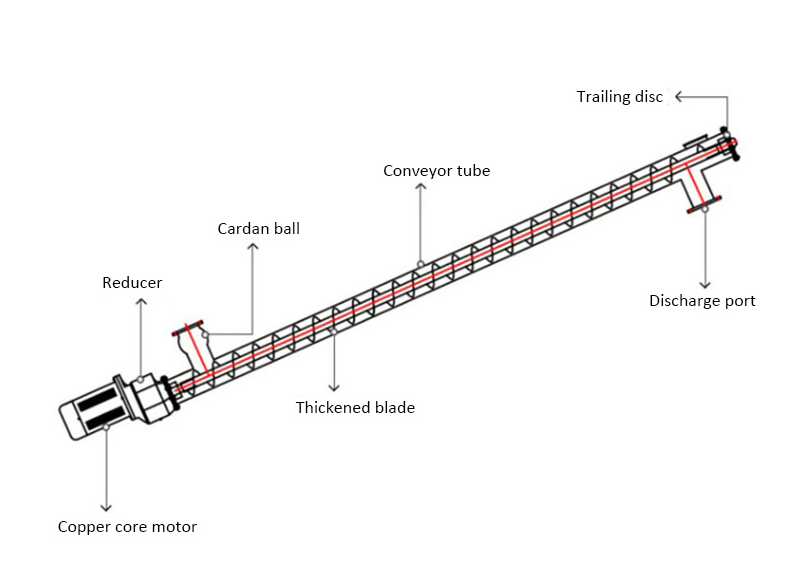

The Fish Feed Screw Conveyor adopts a modular and compact structure. Its core consists of a drive unit, spiral shaft, trough, feed inlet and outlet, and support components. The overall structure is simple, easy to assemble and disassemble, and has few vulnerable parts, ensuring conveying stability while facilitating daily cleaning and maintenance.

Spiral Shaft System: Made of high-strength alloy steel, with a wear-resistant surface treatment to extend service life. The spiral blades can be individually selected according to the material characteristics.

Sealing and Support Structure: The casing adopts a U-shaped groove design, with wear-resistant liners embedded in the inner wall, and a removable cover on the top for easy maintenance. A thrust bearing is installed at the head to withstand axial force, and hanger bearings are installed every 2.5-3.5 meters to prevent the screw shaft from bending due to excessive length.

Drive and transmission device: Typically consists of a variable frequency motor, reducer, and coupling, supporting stepless speed adjustment.

The Fish Feed Screw Conveyor, with its flexible adaptability, is widely used throughout the entire aquaculture and feed processing industry chain. In addition, it can also be used in feed storage unloading, and conveying after cooling of extruded fish feed, comprehensively meeting the material transfer needs of customers of different scales.

Feed production stage: In fish feed production lines, screw conveyors are used to transport crushed raw materials (such as fishmeal and soybean meal) from the silo to the mixer, or from the mixer to the pellet mill.

Fish farm feeding system: Combined with an automatic feeder, the screw conveyor can transport feed from the storage tower to the edge of the aquaculture pond, achieving timed and quantitative feeding through variable frequency control.

Special Material Handling: For fish feed with high oil content, the screw conveyor can prevent material from adhering to the inner wall of the casing due to centrifugal force by adjusting the screw pitch and speed.

| LS type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter (mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Pitch (mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Speed (r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery capacity QΦ=0.33 (m³/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| 功率Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd 1=30m (KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Speed (r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd 1=10m (KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd 1=30m (KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Speed (r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd 1=10m (KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| Power Pd 1=30m (KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Speed (r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| Power Pd 1=10m (KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| Power Pd 1=30m (KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

The Fish Feed Screw Conveyor features a flexible conveying angle design to meet diverse needs from horizontal to vertical. In horizontal or near-horizontal conveying at 0°-20°, the equipment excels in high-speed and stable operation. The material moves evenly under the propulsion of the screw blades, resulting in low energy consumption and minimal wear. It is commonly used for raw material transfer in fish feed processing lines or for short-distance feeding in fish farms. When the angle increases to 20°-45°, the equipment can still maintain high conveying efficiency by optimizing the screw structure and motor power, for example, transporting feed from a low-level storage silo to a high-level hopper, or overcoming terrain obstacles to achieve cross-regional feeding. For vertical conveying, the equipment requires special design, such as adding anti-fall-back baffles and enhancing screw rigidity, to ensure that materials do not slip under gravity, making it suitable for precise feeding in high-rise aquaculture ponds.

The Fish Feed Screw Conveyor, with its flexible adaptability and stable performance, has achieved remarkable results in aquaculture and feed processing scenarios of varying scales. Our customer case studies fully validate the core value of the equipment in increasing production capacity, reducing costs, and adapting to special working conditions.

Large Fish Feed Processing Plant: Previously faced with the problem of low raw material unloading efficiency, the old system took 25-30 minutes per bag to unload 11 different raw materials, relying entirely on forklift support. After introducing a customized screw conveyor, coupled with an unloading device, the unloading time for a 1-ton bag of raw materials was reduced to 5 minutes. The equipment uses a horizontal screw conveyor to precisely transport raw materials to 11 corresponding storage bins, achieving automatic diversion of multiple raw materials.

Large-scale aquaculture farms: Manual feeding presents challenges such as uneven feeding, difficulty in controlling feed quantity, and high labor intensity. Installing a screw conveyor with a dynamic weighing device enables automated and precise feed delivery. The equipment picks up feed from the feed hopper, transports it to each pond via the screw conveyor, and adjusts the feeding amount and frequency in real time via a control box to adapt to the different growth stages of fish species.

High-temperature extruded fish feed processing: Equipment must be heat-resistant and free from structural deformation. A custom-designed inclined screw conveyor made of 304 stainless steel is used, with optimized blade and diameter design for high-temperature conditions, and a fixed chassis to ensure stable inclined operation. The equipment provides uniform feed at a rate of 1.8 tons/hour, and a sealed cover reduces heat loss and dust pollution.

The Fish Feed Screw Conveyor offers a wide range of options covering materials, structures, parameters, and functions to precisely match different customer needs. It can also be equipped with weighing and speed adjustment functions, and can be paired with fixed or mobile models to fully meet the personalized needs of fish farms and feed mills.

Fish feed screw conveyor: Material selection must balance hygiene and durability, and can be chosen according to needs. Food-grade stainless steel is corrosion-resistant, has a smooth surface that is easy to clean, and meets aquatic feed hygiene standards. Wear-resistant carbon steel is less expensive, but requires an epoxy resin or other anti-corrosion coating to improve rust resistance, suitable for small customers with limited budgets in non-food contact areas or dry environments. For high-hardness fish feed, ceramic liners, wear-resistant alloy blades, and other wear-resistant lining accessories can be upgraded to extend the equipment's service life.

Trough type: U-shaped troughs facilitate loading and unloading, are easy to clean and maintain, and are suitable for short-distance transport; circular troughs have strong sealing properties, preventing feed from getting damp and dusty, and are suitable for long-distance or inclined transport.

Conveying layout: Supports multiple installation methods such as horizontal, inclined, and vertical, which can be flexibly selected according to the plant height and equipment connection requirements, without the need for complex foundation modifications.

Inlet/outlet design: Offers multiple connection methods including flanges, bags, and universal joints. Single/multiple outlets can be customized to distribute feed to multiple devices or aquaculture ponds.

Roller design: Rollers can be added to the bottom of the equipment for easy relocation after use.

The price of a Fish Feed Screw Conveyor varies considerably depending on the model, material, and features. Our factory's prices range from 450.00 to 3,200.00 RMB per set. Basic carbon steel screw conveyors are suitable for small-scale aquaculture farms or short-distance horizontal conveying, and are typically priced under 1,000 RMB. Stainless steel, corrosion-resistant designs, or high-capacity models may exceed 2,000 RMB. Furthermore, customized equipment supporting inclined or vertical conveying and equipped with variable frequency speed control will further increase the price. Customers can choose flexibly based on their aquaculture scale, conveying distance, and budget.

As a seasoned manufacturer in the aquaculture equipment field, we specialize in the research and development of fish feed screw conveyors, offering a variety of materials including carbon steel, stainless steel, and food-grade plastics to meet the conveying needs of different feed characteristics (such as oil content and moisture). Our products cover three main types: shafted, shaftless, and flexible hose screws, supporting horizontal, inclined, and vertical full-angle rotation conveying. We can also customize the screw pitch, blade angle, and drive power according to the scale of the aquaculture farm, spatial layout, and feeding accuracy requirements. Whether for flexible feeding in small family ponds or continuous operation in large-scale factory farms, our modular design enables efficient matching, helping customers improve feed utilization and aquaculture efficiency.

What other materials can the Fish Feed Screw Conveyor convey?

It can convey a variety of granular and powdery materials with similar characteristics. This includes grains such as corn flour, wheat bran, and soybean meal, as well as agricultural by-products such as distillers' grains and wheat bran. Furthermore, for feed additives, such as vitamin premixes and mineral powders, the equipment ensures clean transport through food-grade materials and a sealed structure.

What is the hourly conveying capacity of a Fish Feed Screw Conveyor?

The hourly conveying capacity of a fish feed screw conveyor can be flexibly adjusted according to equipment specifications to adapt to different needs. Small models convey 0.5-5 tons per hour, suitable for small-scale fish farms; medium-sized models convey 5-15 tons per hour, suitable for medium-sized feed mills; large models, with optimized design, can convey up to 20 tons or more per hour.

What is the service life of a Fish Feed Screw Conveyor?

The service life of a fish feed screw conveyor is affected by materials, operating conditions, and maintenance, generally around 10 years. The specific service life will depend on your usage frequency, usage time, and the characteristics of the conveyed materials.

In the modern aquaculture and feed processing industry, the Fish Feed Screw Conveyor, with its advantages of compact structure, high conveying efficiency, and strong adaptability, has become a key piece of equipment connecting feed production and aquaculture.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!