Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

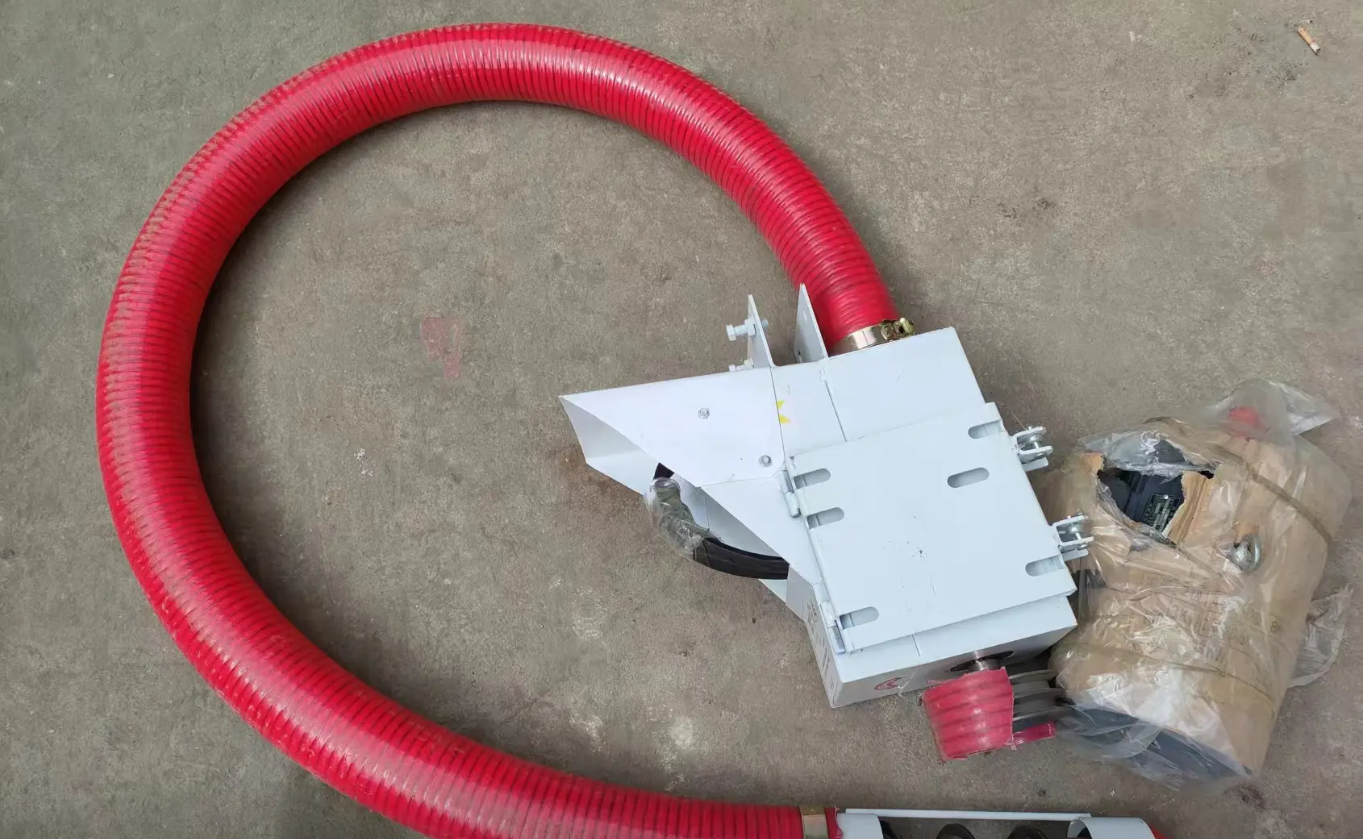

Corn Hose Conveyor can be used for horizontal, inclined and vertical conveying. The characteristics of the hose enable it to be used for conveying in different scenarios, and is particularly suitable for working in complex and narrow places.

Material: PVC

Capacity: 0.1t/h - 30T/h

Width or diameter: 160mm

Weight: 80kg

Power: 3kw

Voltage: 110V/220V/380V or customized according to demand.

Applicable industries: building materials stores, manufacturing plants, food and beverage plants, farms, construction projects, energy and mining, food and beverage stores

Corn Hose Conveyor is a device specially used for conveying corn grains. It combines the flexibility of the hose and the performance of the conveyor. It can convey corn from the starting point to the end point through the hose, providing convenience and adaptability for corn transportation, and occupies an important position in grain transportation and related industries.

The corn hose conveyor mainly operates based on the principle of spiral conveying. Its core component is a hose with a spiral spring inside. When the motor is started, the motor shaft is connected to the spiral spring through a screw, driving the spiral spring to rotate at high speed. Corn and other materials at the collection port will continue to rise along the spiral angle of the spring under the thrust generated by the rotating spring. As the materials move, they are gradually conveyed to the discharge port.

The main advantages of corn hose conveyor are as follows.

High conveying capacity: The conveying capacity per hour can reach 3-30 tons. The specific conveying capacity depends on factors such as the model of the equipment, the motor power, and the nature of the conveyed material.

Easy to move: The whole machine is relatively light, generally around 40-140kg, and occupies a small area, which makes the corn hose conveyor have excellent mobility. It can be easily moved and installed between different work sites without complex fixing facilities.

Protect corn particles: When conveying granular materials such as corn, the design of the spiral spring and the material conveying method can effectively reduce the collision and friction of the material, thereby reducing the breakage rate of the material.

Multi-scenario use: In addition to conveying corn, the conveyor can also be widely used in the conveying of a variety of granular materials, such as wheat, soybeans, rice, sorghum, plastic particles, resin particles, etc.

Relatively low price: The equipment cost of the corn hose conveyor is relatively low, and it has a higher cost-effectiveness compared with some large and complex conveying equipment.

The composition structure of the corn hose conveyor is simple, mainly composed of the following components.

Power system: Usually powered by a motor. The type and power of the motor depend on the conveying capacity and working environment of the conveyor. There is a gasoline or diesel engine as the power source, which makes it more mobile and adaptable.

Coil spring assembly: This is a key component of the corn hose conveyor. The diameter, pitch and material selection of the spring will be optimized according to the characteristics of the conveyed material (such as particle size, density, fluidity, etc.).

Hose part: As a channel for material transportation, the hose needs to have certain flexibility and wear resistance. It is generally made of high-strength rubber or plastic materials, such as tendon hoses.

Feeding and discharging device: The feeding device is usually designed as a funnel-shaped collection port to facilitate the concentration and guidance of materials into the hose.

| Model | Length (Meters) | Pipe diameter |

Loading Capacity

(t/h)

|

Motor phase

power(kw)

|

Installation | Structure |

| RLS100 | 4 meter | 100mm | 5-8 | Single phase-3kw | Vehicle mounted | Steel screw blade inside |

| 5 meter | ||||||

| 6 meter | ||||||

| 8 meter | ||||||

|

.....

Customized

|

||||||

| RLS120 | 4 meter | 120mm | 10-15 | Three phase-4KW | Vehicle mounted | Steel screw blade inside |

| 5 meter | ||||||

| 6 meter | ||||||

| 8 meter | ||||||

|

.....

Customized

|

Corn hose conveyors are widely used in multiple scenarios using their own advantages.

Agricultural production link: During the harvest season, farmers can use it to quickly transport corn from the fields to transport vehicles, and then transport it to the warehouse or grain purchasing point at home. In the warehouse, corn can also be stacked and piled up by conveyors to achieve a reasonable storage layout.

Grain storage industry: When grain is put into storage, the feed port of the conveyor can be connected to the transport vehicle to directly transport corn to the designated granary position; when it is out of storage, the corn in the granary can be quickly transported to the transport vehicle or other processing equipment to ensure the smooth flow of grain.

Feed mill processing plant: Granular raw materials such as corn and soybean meal can be transported to the batching system for mixing and processing.

Corn processing: The hose conveyor is used to transport corn raw materials to different processes such as cleaning, drying, crushing, and packaging to achieve continuous production.

Feed mill raw material transportation: The hose conveyor can transport corn to equipment such as mixers and crushers to improve production efficiency.

When purchasing corn hose conveyors, we must combine various issues and needs to select the most suitable conveying equipment.

Conveying distance and output restrictions: Purely relying on hoses for long-distance and large-volume corn transportation may have efficiency and power limitations.

Material characteristics: The moisture content, particle size and other characteristics of corn may affect the effect of hose transportation. If your corn is relatively wet, it may affect the conveying effect of corn.

Wear problem: Long-term transportation of hard corn particles may cause certain wear on the inner wall of the hose, which requires regular inspection and replacement.

We have many different types of customers in the corn conveying industry. The following are different types of customer cases

Post-harvest corn transportation on large farms: The customer's planting area exceeds 5,000 acres, and the annual corn output is as high as tens of thousands of tons. After the corn is harvested, it needs to be quickly transported from the field to the transport vehicle or temporary storage point. A mobile corn hose conveyor equipped with a high-power fan and wear-resistant hose is configured for the customer, which can directly transport corn from the harvester to the transport vehicle or temporary storage point.

Raw material transportation in grain processing plants: The customer is mainly engaged in the deep processing of corn starch and corn oil. The factory needs to process hundreds of tons of corn raw materials every day, and requires a closed, low-energy consumption conveying equipment. A pneumatic conveying system is designed for the customer, using wear-resistant hoses and high-efficiency fans to achieve fully enclosed transportation of corn raw materials.

Port corn loading and unloading transit: The customer's main business is to transport corn from the port to all parts of the country, and it needs to quickly unload corn from the cargo ship to the truck or train. A set of mid-drive corn hose conveyor system is configured for the customer, equipped with multi-section hose and control system with adjustable conveying direction, which can directly convey corn from cargo ship to truck or train car.

The price of corn hose conveyor varies due to equipment specifications, configuration, brand and function differences. Generally speaking, the price of small or basic models may be 1-2 pieces $290.00 >= 3 pieces $280.00. The main factors affecting the price include hose material, power system performance, conveying capacity, and automation control level. If you need it, please contact us!

Corn hose conveyor applications cover many fields from agricultural production to grain processing, warehousing logistics, food processing, etc. Its flexible and closed conveying characteristics make it an indispensable equipment in modern agricultural production and grain processing.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!