Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Chemical shaftless screw conveyor has become an ideal equipment for chemical enterprises to handle various complex materials with its unique design advantages and excellent performance, bringing significant improvement to the industry's conveying efficiency.

Price: $750.00-$3,960.00/set

Type: single shaftless/double shaftless

Diameter: 150 - 470 mm

Installation angle: 0-15° or 0-30°

Length: 0-20 m or 0-30 m

Output: 0.8 tons/hour - 45 tons/hour

Power: 0.55 kW - 5.5 kW Speed: 29 rpm

Structural material: hot-dip galvanizing, 304/316 stainless steel, hardened alloy, etc.

Angle: <40 degrees

Application: It can effectively convey various types of chemical materials such as viscous, high-water content, and wet materials, plastic particles, resins, adhesives, asphalt, etc.

Chemical shaftless screw conveyor is a special conveying equipment designed for the chemical industry. It adopts a center shaftless structure and anti-corrosion materials. It can safely convey all kinds of corrosive, viscous, toxic and harmful chemical materials, and completely solve the corrosion and leakage problems of traditional conveying equipment. It can quickly convey different types of chemical products such as powder, granules, blocks, strips, etc. through the shaftless design. It can perfectly combine with other equipment for joint production to complete the process production line.

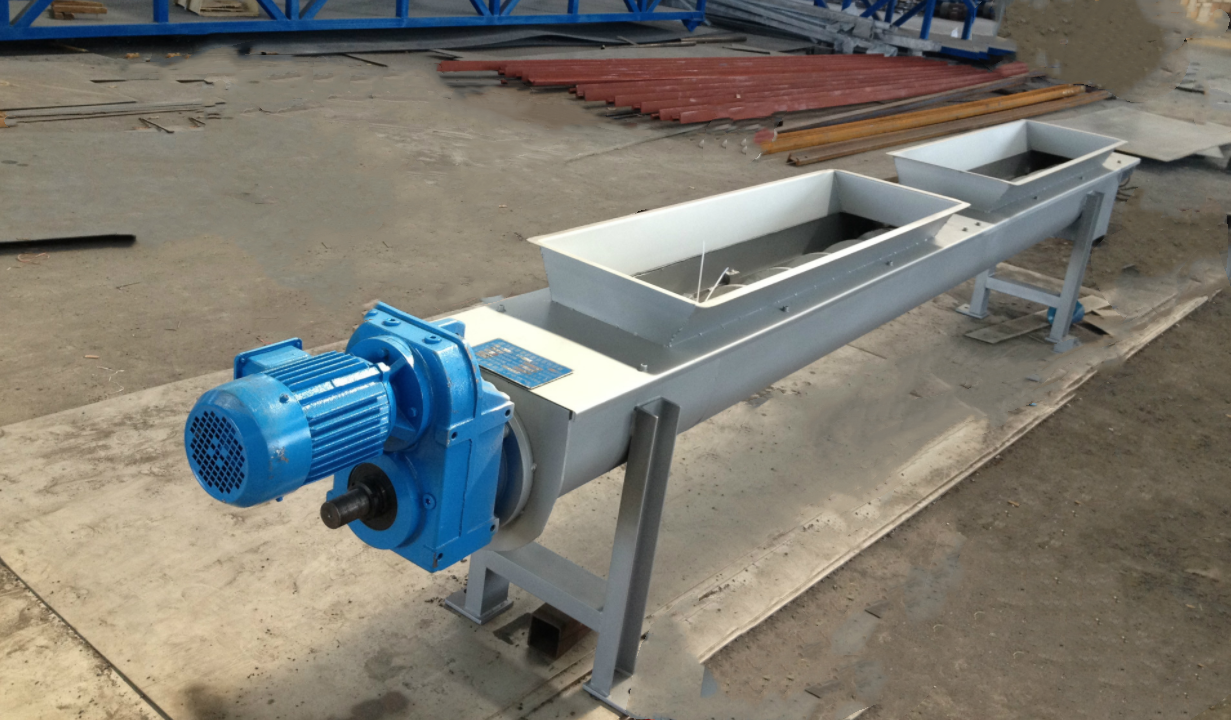

Chemical shaftless screw conveyors are mainly divided into U-shaped trough type and tube type. The U-shaped trough type is easy to maintain and suitable for viscous materials; the tube type has good sealing and is suitable for toxic, flammable and explosive materials.

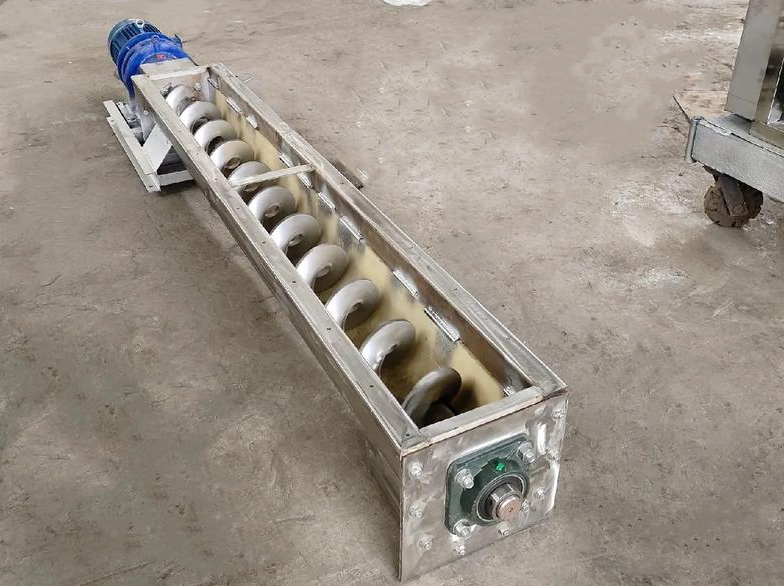

U-shaped trough shaftless screw conveyor: The trough body is U-shaped open or covered and closed, and the center shaftless spiral blades are in direct contact with the material. It is often equipped with wear-resistant liners such as polyethylene and ceramics. It is easy to maintain and the open structure is easy to check and clean; it has a wide range of applicability and strong customizability. The width and depth of the trough body can be adjusted according to the characteristics of the material.

Tube shaftless screw conveyor: adopts a fully enclosed round tube structure, with a small gap between the spiral blade and the tube wall, excellent sealing, and can be made of stainless steel, titanium alloy or plastic lining. It is completely sealed to prevent volatilization and leakage, suitable for toxic and harmful materials; it has dust and explosion-proof characteristics, suitable for flammable and explosive chemicals, can be installed horizontally, tilted or vertically, and the conveying distance is up to 30 meters.

The shaftless design of the chemical shaftless screw conveyor prevents winding and blocking, and the corrosion-resistant material is suitable for strong acids and alkalis. It is fully sealed to prevent leakage, ensure the safe transportation of chemical materials, and reduce maintenance costs.

Super strong corrosion resistance: using 316L stainless steel/titanium alloy and other materials, resistant to acid and alkali corrosion

Completely sealed: fully enclosed structure design to prevent material leakage and volatilization

Anti-sticking design: special surface treatment to avoid material adhesion and scaling

Anti-crystallization and clogging design: for easy crystallization materials, the tank body can be integrated with a jacket heating system, combined with a spiral blade 0.5mm mirror polishing to prevent material crystallization and adhesion in the low temperature zone.

The chemical shaftless screw conveyor adopts a special structural design without a central shaft. The wear-resistant spiral blades are driven by a motor to rotate to realize the closed conveying of various chemical materials. Its working principle is based on the continuous rotation of the spiral blades to push the material to move axially along the U-shaped trough or tubular channel. It is particularly suitable for corrosive, viscous or toxic and harmful chemical materials.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

|

Model |

Diameter (mm) |

Rated speed (r/min) |

Reference capacity (m³/h) |

Motor power (Kw) |

Admission biggest gradient (o) |

|

LS114 |

114 |

84-130 |

1 |

0.75-18.5 |

<60 |

|

LS133 |

133 |

84-130 |

1.3 |

0.75-18.5 |

<60 |

|

LS159 |

159 |

84-130 |

5 |

0.75-18.5 |

<60 |

|

LS219 |

219 |

84-130 |

15 |

0.75-18.5 |

<60 |

|

LS245 |

245 |

84-130 |

20 |

0.75-18.5 |

<60 |

|

LS273 |

273 |

84-130 |

30 |

0.75-18.5 |

<60 |

|

LS315 |

315 |

84-130 |

40 |

0.75-18.5 |

<60 |

|

LS400 |

400 |

60-100 |

45 |

0.75-18.5 |

<60 |

|

LS500 |

500 |

60-100 |

70 |

0.75-18.5 |

<60 |

|

LS600 |

600 |

60-100 |

100 |

0.75-18.5 |

<60 |

The chemical shaftless screw conveyor is suitable for the transportation of corrosive liquids and slurries, chemical waste residues and hazardous wastes, and is suitable for a variety of harsh chemical working conditions.

Raw material transportation: In the production of plastic particles such as polyvinyl chloride and polyethylene, the shaftless screw conveyor can stably transport resin powder to the extruder to avoid dust flying and agglomeration.

Waste treatment: Chemical wastewater treatment plants use the fibrous impurities (such as synthetic fibers and plastic fragments) intercepted by their conveying grid decontamination machines to prevent clogging of pipes and pump bodies.

Reactor feeding: In the process of pesticide and dye synthesis, the amount of catalyst and additives added is accurately controlled through the frequency conversion speed regulation function to ensure the stability of the reaction.

Packaging line matching: Linked with the automatic packaging machine, quantitative filling of powdered materials such as fertilizers and coatings can be achieved, reducing manual intervention and improving packaging efficiency.

The blades of the chemical shaftless screw conveyor are in direct contact with various corrosive, flammable and explosive or high-viscosity chemical materials. The material selection must take into account corrosion resistance, wear resistance, strength and cost.

Stainless steel material: 304 stainless steel is suitable for weakly corrosive materials, with moderate cost and basic rust resistance, but not resistant to chloride ion corrosion; 316L stainless steel contains molybdenum, has better corrosion resistance, can cope with moderate corrosion conditions, and is a common choice in the chemical industry.

Special alloy material: Hastelloy alloy is highly resistant to corrosion by strong acid, strong alkali and fluorine-containing media, and is suitable for conveying high-purity materials in fine chemicals, but the cost is relatively high; titanium alloy is resistant to corrosion by oxidizing media at high temperatures of ≤300℃, and is lightweight and high-strength, making it suitable for conveying high-temperature chemical slurries.

Non-metallic and composite materials: Ultra-high molecular weight polyethylene is resistant to acid and alkali, non-sticky, and suitable for viscous materials and low-concentration corrosive slurries. Ceramic lining blades are made of a metal matrix and alumina ceramics, which are both wear-resistant and corrosion-resistant, and are suitable for conveying corrosive materials containing hard particles.

As a manufacturer, our chemical shaftless screw conveyor serves customers in multiple industries: fine chemical companies use it to ensure the purity of pharmaceutical intermediates, sewage treatment plants rely on it to convey corrosive sludge, and hazardous chemical plants use it to achieve safe transportation, adapting to the special transportation needs of various industries.

Chemical raw material transportation: Large-scale fine chemical enterprises have long been committed to the production of high-purity chemicals. When transporting raw materials such as pharmaceutical intermediates, traditional equipment frequently has problems with material residue and cross-contamination, which seriously affects product quality. After the introduction of the chemical shaftless screw conveyor, the 316L stainless steel electrolytic polishing process is used to reduce material adhesion. With the CIP online cleaning system, deep cleaning can be completed within 30 minutes.

Chemical wastewater treatment: Sewage treatment plants need to treat a large amount of wastewater containing heavy metal ions and high concentrations of acid and alkali. The sludge produced by precipitation is highly corrosive and viscous. In the past, conveying equipment was often shut down for maintenance due to corrosion damage and blockage, affecting the efficiency of sewage treatment. After selecting the tubular closed chemical shaftless screw conveyor, the main body of the equipment is made of Hastelloy, which is resistant to strong acid and alkali corrosion and effectively overcomes the high viscosity resistance of sludge.

Optimization of hazardous chemical production and transportation: The production process involves the transportation of a variety of flammable, explosive, toxic and harmful materials, such as organic peroxides and highly toxic halides. The original conveying equipment has poor sealing, and there is a risk of leakage from time to time, which poses a great safety hazard. A customized chemical shaftless screw conveyor is used, with a fully enclosed round tube structure and a double-layer sealing design to prevent material volatilization and leakage. Titanium alloy is used as the material, which has excellent pressure resistance and corrosion resistance. In view of the explosive characteristics, it is equipped with an intrinsically safe electrical system and an anti-static grounding device.

Choosing a suitable chemical shaftless screw conveyor requires a comprehensive evaluation from five dimensions: material characteristics, conveying parameters, equipment performance, environmental adaptability and economy.

Accurately match material characteristics: The selection of chemical shaftless screw conveyors must be based on material characteristics as the primary basis. For large particles/block materials, a model with a screw diameter of ≥400mm and a pitch of 300-500mm should be selected to prevent blockage; powdery/fine particles are suitable for models with a diameter of 200-300mm and a pitch of 150-250mm to improve conveying efficiency. Viscous/entangled materials should give priority to shaftless design and increase the screw torque to avoid entanglement; high-humidity materials should use anti-stick coating or stainless steel.

Clearly define the conveying parameters: Conveying parameters directly affect equipment selection and production efficiency. The conveying volume needs to be determined according to production needs. For example, large-scale fertilizer plants need to select models with a diameter of ≥400mm and a speed of ≥50rpm to meet the conveying needs of 50-100 tons per hour. In terms of conveying distance and angle, the length of a single horizontal conveyor can reach 30 meters, and long-distance conveying requires multi-stage series connection.

Evaluate equipment performance and reliability: The quality of key components needs to be strictly controlled. The thickness of the spiral blade is recommended to be ≥10mm, and the material needs to match the material characteristics; the drive motor is preferably an adjustable speed variable frequency motor to adapt to fluctuations in conveying volume.

Adapt to working environment conditions and spatial layout: High temperature environments require high temperature resistant models, high humidity environments require rust prevention, and explosion-proof environments require explosion-proof motors and control boxes. In terms of spatial layout, small places should use small and compact tubular or small U-shaped screw conveyors.

Dahan Machinery has been focusing on the research and development and manufacturing of biomass shaftless screw conveyors for many years. We have a professional technical team that can customize exclusive conveying solutions based on different customer needs. In terms of production technology, we use advanced equipment and exquisite craftsmanship to ensure high product quality. The shaftless design of the conveyor produced can effectively avoid material entanglement and is suitable for all kinds of biomass materials, such as straw, wood chips, etc. The conveying length of a single machine can reach 30 meters. In addition, the material and conveying angle can also be customized according to your on-site conditions.

In chemical production, the transportation of corrosive media, viscous slurries, solid waste and other materials always faces problems such as equipment corrosion, blockage and leakage, and pollution risks. With its exclusive design of corrosion resistance and anti-blocking, the chemical shaftless screw conveyor has become the core equipment for material transfer in the chemical, pharmaceutical, printing and dyeing industries, fundamentally solving the adaptation pain points of traditional conveying equipment.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!