Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

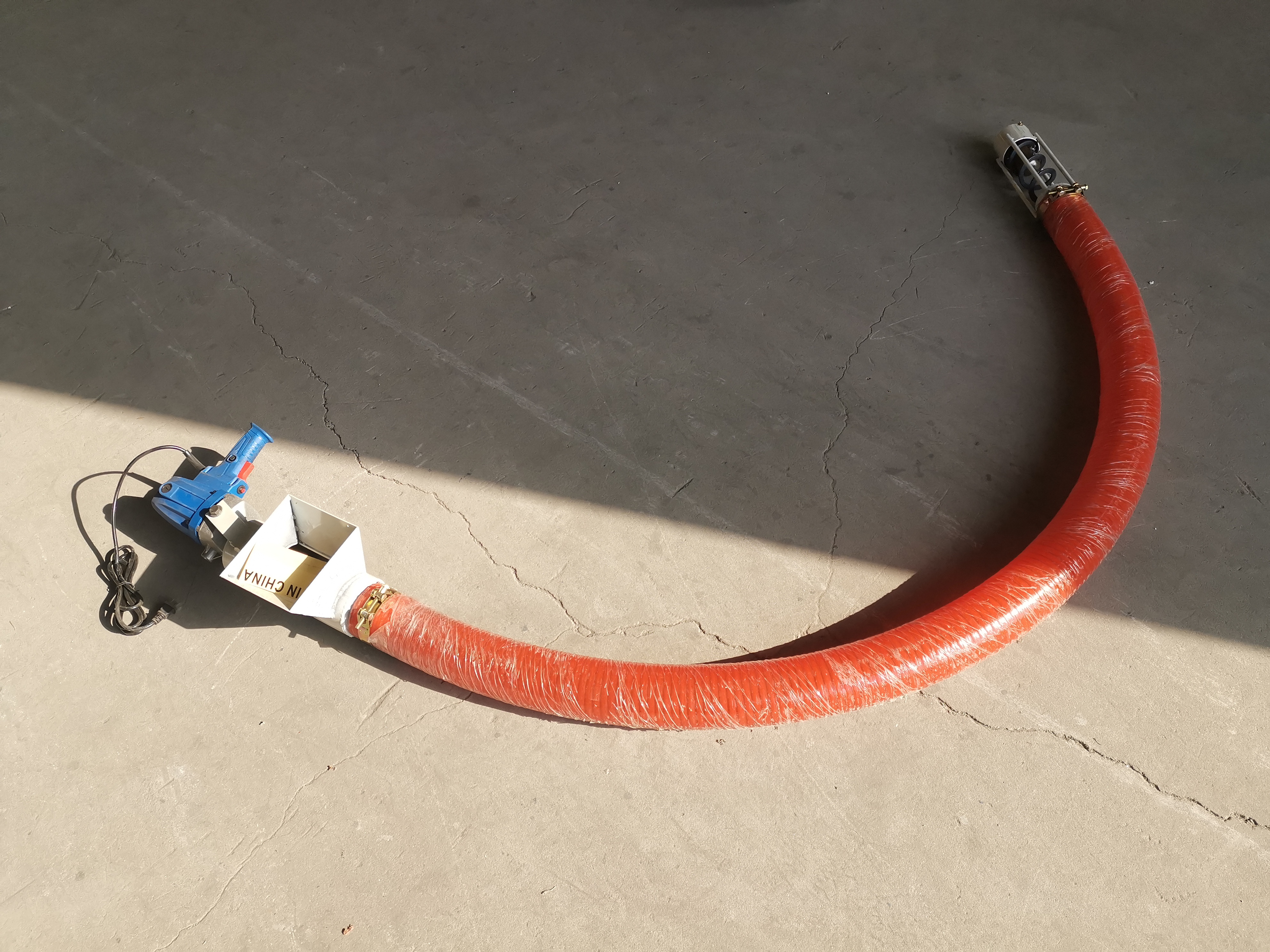

Flexible screw conveyor is a new type of advanced material handling equipment. It is small and flexible, easy to assemble, and can be used for material transportation after simple assembly. It can be transported horizontally, inclined, and vertically.

Load capacity: 8 tons

Model: RLS-160

Power: 3KW

Width or diameter: 160mm

Belt material: pvc

Length: Customized 1~30m

Application: rice, wheat, corn, sorghum, dry sand, pebbles, slag, cement, wood chips, etc.

Cement Hose Grain Suction Machine is a device used for cement particle processing. It mainly sucks cement particles from one place to another by sucking them with a hose. Combining the advantages of the hose and the spiral, cement can be better transported to different scenes. The hose made of beef tendon is more durable and can reach a length of 30 meters. It can also be used to transport sand, corn, and wheat.

The features and advantages of Cement Hose Grain Suction Machine are mainly reflected in the following points

Anti-blocking design: The equipment has an anti-blocking design, which can effectively cope with the characteristics of high density and easy blockage of cement particles.

Anti-adhesion treatment: Through special surface treatment or design, the adhesion of cement particles during transportation is reduced to keep the equipment clean.

Strong adaptability: The flexibility of the hose enables the cement hose suction machine to adapt to various transportation routes and site layouts, which improves the flexibility of the equipment.

Enclosed dustproof: The entire transportation process is carried out in a closed pipeline, which effectively avoids dust flying, improves the working environment, reduces material loss, and meets the requirements of modern industry for environmental protection.

The cement hose suction machine uses the negative pressure generated by the vacuum pump to suck cement particles from the storage container into the hose and transport them to the designated location. Its core components include vacuum pump, suction hose, filtration system and control system. The vacuum pump is responsible for generating negative pressure, the suction hose is responsible for conveying materials, and the filtration system ensures that the dust in the air is effectively filtered to protect the environment and the health of operators.

The main structure of the cement hose suction machine mainly includes the following parts.

Suction machine head: including feed port and discharge port, used to absorb and convey cement particles or powder.

Hose: soft and wear-resistant hose, used to convey cement particles, with certain bendability, adaptable to different conveying paths.

Conveying spiral: located inside the hose, through rotation drive, cement particles are conveyed to the destination along the hose spiral.

Transmission device: provides power to drive the rotation of the conveying spiral to realize the cement conveying operation.

| Model |

Length (Meters) |

Pipe diameter |

Loading Capacity (t/h) |

Motor phase power(kw) |

Installation | Structure | Conveying height |

| RLS-100 | 3-30m | 100mm | 5-8 | Single phase 3KW | Vehicle mounted | Steel screw blade inside | Depends on case |

| RLS-120 | 120mm | 10-15 | Three phase 4KW | ||||

| RLS-160 | 160mm | 15-20 | Three phase 5.5KW | ||||

| RLS-180 | 180mm | 20-30 | Three phase 11KW |

The cement hose suction machine uses its own advantages and is mainly used in the following scenarios.

Cement production plant: used to transport cement particles or powder to different production links, such as grinding, sintering, etc., to improve production efficiency and automation level.

Construction site: On the construction site, the cement hose suction machine can transport cement particles from the warehouse to the concrete mixing station or the specific construction location, which is convenient and efficient.

Storage facilities: used for the transportation and storage of cement in the warehouse, which is convenient for management and use.

Different types of cement will produce different effects when using hose spiral conveyors.

Particle size and shape: The size and shape of cement particles directly affect the conveying efficiency of the suction machine. Particles that are too large or irregular in shape may cause blockage, while particles that are too small may increase the amount of dust and affect the performance of the filtration system.

Density and fluidity: The density and fluidity of cement determine its conveying speed and stability in the hose. High-density cement requires stronger negative pressure to be effectively conveyed, while cement with poor fluidity may cause poor conveying.

Humidity and viscosity: The humidity and viscosity of cement have a significant impact on the working efficiency of the suction machine. Cement with high humidity or high viscosity is prone to form lumps on the inner wall of the hose, affecting the conveying efficiency and may even cause equipment failure.

Chemical composition: The chemical composition of cement determines its corrosiveness and the degree of wear on the equipment. Some cements with special ingredients may have special requirements for the material of the suction machine to prevent corrosion and extend the life of the equipment.

We have many years of professional R&D and production experience, and have been committed to providing customers with high-performance, high-quality and reasonably priced cement hose suction machines. In the production process, we are equipped with advanced production equipment and a complete production line. The large-scale production model effectively reduces the production cost, which enables us to give customers a very competitive price while ensuring product quality: 1 - 9 sets $460.00, >= 10 sets $450.00.

As a professional conveying equipment, the cement hose suction machine plays an important role in the cement industry. By fully understanding the characteristics of cement as a material, the design and application of cement hose suction machines can more effectively improve production efficiency and reduce losses, helping the cement industry to develop in a more automated and efficient direction. The emergence of this equipment provides a convenient and efficient solution for cement production and transportation, and promotes the modernization of the cement industry.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!