Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Barium Sulfate Screw Conveyor is a fully enclosed screw conveyor for transporting barium sulfate powders, providing a solution for material handling in complex environments. We support non-standard customization to adapt to the spatial layout and capacity requirements of different production lines. It allows for flexible adjustment of the tilt angle from 0-90°, ensuring stable operation whether conveying horizontally, vertically, or at an angle. Supporting multi-point feeding design, it can meet the needs of simultaneous feeding from multiple stations along the same conveying path. Combined with a mobile frame design, the equipment can be quickly deployed to different production areas.

Barium sulfate is in powder or fine granular form, and under some conditions contains trace amounts of corrosive media. High purity is also required. Therefore, the material of the Barium Sulfate Screw Conveyor must balance corrosion resistance, cleanliness, and structural strength. We offer 304, 316, and PP materials.

304 Stainless Steel: Possesses basic corrosion resistance and good rust prevention. Its moderate hardness and ease of processing make it suitable for conveying conventional neutral barium sulfate materials.

316 Stainless Steel: Based on 304 stainless steel, the addition of molybdenum significantly enhances its corrosion resistance and acid/alkali resistance. It is suitable for barium sulfate materials containing trace amounts of corrosive components, or for production environments with high humidity and high cleanliness.

PP Material: A non-metallic corrosion-resistant material with excellent chemical stability. It does not react with acidic or alkaline media and is suitable for transferring highly corrosive barium sulfate materials.

The Barium Sulfate Screw Conveyor, with its corrosion-resistant materials and multi-angle (inclined/horizontal) conveying capabilities, has become a popular choice for conveying barium sulfate powder in various industries. Its main features include the following:

Good Sealing: Employing a fully enclosed trough design, the head, middle, and tail sections are bolted together. Gates are installed at the inlet and outlet to effectively prevent material leakage.

Multi-directional Conveying: By adjusting the rotation direction of the screw shaft, the equipment can achieve bidirectional conveying, meeting the needs of complex processes.

High Adaptability: Available in 304 stainless steel, 316 stainless steel, and PP materials to suit neutral, weakly corrosive, and strongly corrosive working conditions, completely eliminating metal impurity contamination.

Customizable: We can customize suitable screw conveyors based on site conditions, ensuring high-speed operation of the entire production line.

The Barium Sulfate Screw Conveyor is a specialized device designed for powdery, easily dusty, and partially corrosive barium sulfate materials. It features a compact structure and strong sealing.

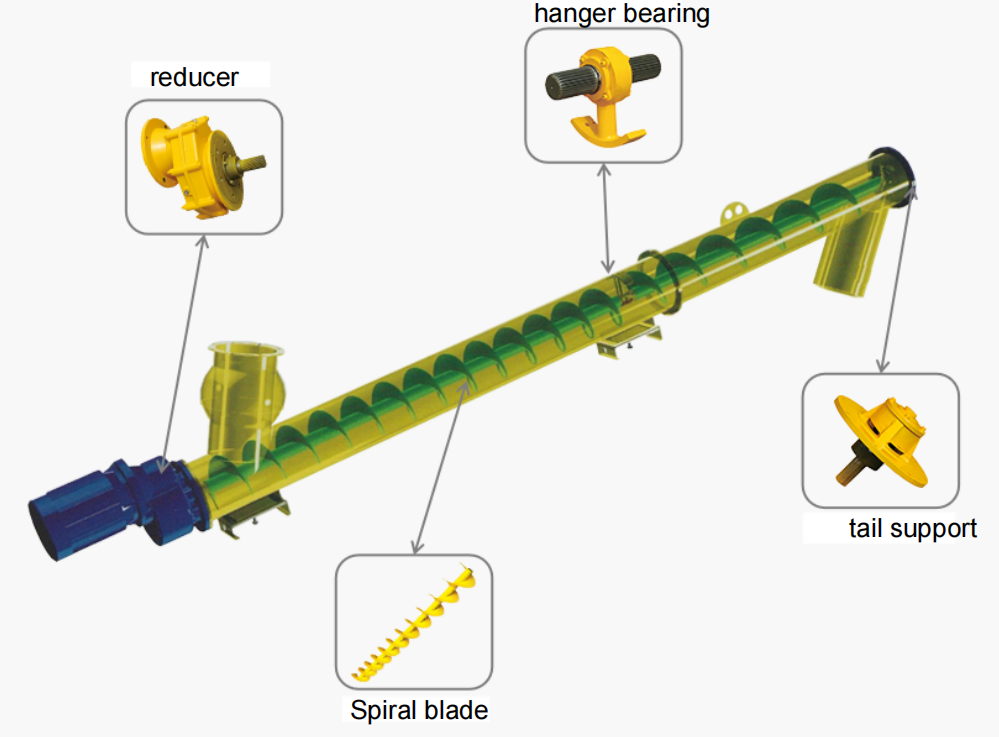

Drive Unit: As the core power unit, it consists of a variable frequency motor, a reducer, and a coupling. The variable frequency motor allows for flexible speed adjustment, preventing material accumulation or interruption; the reducer lowers the speed while increasing torque, adapting to different conveying distances and material resistances; the coupling ensures a stable connection between the motor and the screw shaft.

Conveying Body: The core carrier for material transfer, comprising a screw shaft, screw blades, and a sealed cylinder. The screw shaft is manufactured using an integrated forging process, resulting in high rigidity, low deflection, and resistance to deformation during long-term operation. The screw blades are designed with a constant or variable pitch structure based on the flowability of barium sulfate. The cylinder is made of 304 stainless steel, 316 stainless steel, or PP material, and its fully enclosed design effectively prevents dust leakage.

Inlet and Outlet: Includes an inlet, an outlet, and matching seals. The inlet is designed as a flange or chute structure for connection to upstream machinery; the outlet is equipped with an adjustable baffle to control the material output speed.

When the drive unit rotates the screw shaft, the barium sulfate particles, due to their own gravity and friction with the trough wall, do not rotate synchronously with the screw shaft but slide axially, forming a continuous material flow. This process is similar to the translational motion of a nut on a screw. Once the nut is clamped and fixed, the rotation of the screw pushes the nut in a straight line, while the barium sulfate particles are directionally conveyed through the rotation of the helical blades.

| Specifications | Spiral diameter (mm) | Pitch(mm) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) |

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3.0 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Medium | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62.0 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

| Material size | Material abrasiveness | Recharge Factor | K | A | |||||||

| Powder | Non-abrasive Semi-abrasive | 0.35-0.4 | 0.0415 | 75 | |||||||

| Powder | Grindability | 0.25-0.3 | 0.0565 | 35 | |||||||

| Small pieces a<60mm | Non-abrasive Semi-abrasive | 0.25-0.3 | 0.0537 | 45 | |||||||

| Small pieces a<60mm | Non-abrasive Semi-abrasive | 0.2-0.25 | 0.0645 | 25 | |||||||

To address the characteristics of barium sulfate materials in different fields, we customize different models of Barium Sulfate Screw Conveyors for different customers, successfully solving industry problems such as corrosion, dust, and substandard purity, and helping to improve production line efficiency.

Chemical Barium Sulfate Transfer: The original conveying equipment experienced frequent shutdowns for maintenance due to corrosion from residual hydrochloric acid. After customizing a duplex stainless steel helical shaft and a PTFE-lined trough, the equipment's acid and alkali resistance increased by 3 times, and the helical shaft wear was only 0.8mm.

Building Material Barium Sulfate Transfer: Modifying the original fixed conveyor took 4 hours, affecting production efficiency. After customizing a mobile screw conveyor, rapid deployment was achieved through heavy-duty casters and a hydraulic lifting support, reducing the single movement time to 15 minutes.

Barium Sulfate Conveying in Pharmaceuticals: The original single-point feeding resulted in a mixing uniformity of only 82%, leading to significant batch-to-batch variations. After customizing a clean-type screw conveyor, two additional feeding ports were added, enabling precise proportioning of barium sulfate and excipients. The 316L stainless steel polishing and closed-loop control meet hygiene standards, improving mixing uniformity to 99.9%.

As a core connecting device for material transfer, the Barium Sulfate Screw Conveyor can be flexibly combined with upstream raw material processing equipment and downstream deep processing and packaging equipment, depending on the barium sulfate production process and processing technology, to achieve fully automated conveying from raw material entry to finished product exit.

Mixer: Barium sulfate modification and batching processes. In the coatings and plastics industries, barium sulfate often needs to be mixed with additives such as titanium dioxide and resins. The screw conveyor can precisely deliver a fixed amount of barium sulfate powder to the mixer, and with the help of a frequency converter control system, precise control of the batching ratio can be achieved.

Vibrating Screen: Barium sulfate powder grading and screening. The screw conveyor transports raw materials to the inlet of a vibrating screen, which separates barium sulfate powder into different finenesses according to particle size requirements.

Packaging Machine: The screw conveyor directly transports the finished barium sulfate powder to the packaging machine for packaging and transfer.

DaHan Machinery manufactures a full range of Barium Sulfate Screw Conveyors in 304/316 stainless steel and PP materials, suitable for barium sulfate conveying conditions with different corrosion levels. The equipment boasts an IP65 sealing rating and a dust leakage rate of less than 0.1%. We provide a full-process service from selection and non-standard customization to after-sales support. Products can be customized to match the location, shape, and quantity of inlet and outlet ports with upstream and downstream equipment. We can sell complete sets of equipment. As the source manufacturer, there are no middlemen, ensuring the best price for you.

With its core advantages of corrosion resistance, excellent sealing, and strong adaptability, the Barium Sulfate Screw Conveyor has become the preferred choice for many companies. It not only solves the pain points of dust pollution, material loss and equipment corrosion in the barium sulfate transportation process, but also ensures production continuity through stable and fast transportation, helping enterprises improve production efficiency and reduce overall costs.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!