Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Barium Sulfate Auger Screw is a special screw conveyor for conveying barium sulfate powder and its mixed pastes. Its enclosed structure design effectively solves the problems of dust and contamination during barium sulfate transportation. A single unit can achieve a maximum conveying distance of 30 meters, and multiple units can be connected for ultra-long-distance transport, easily adapting to different workshop layouts and conveying scenarios. Based on the characteristics of barium sulfate and operating conditions, we offer carbon steel, stainless steel, and PP materials, suitable for general operating conditions, corrosion-resistant operating conditions, and the conveying requirements of food-grade and pharmaceutical-grade barium sulfate, meeting the needs of large-scale and standardized barium sulfate transportation.

The Barium Sulfate Auger Screw features a sealed structure to prevent dust generation and reduce losses. Available in carbon steel, stainless steel, and PP, it boasts a simple structure, easy maintenance, and stable operation, making it suitable for large-scale transport in various industries such as chemicals and pharmaceuticals.

Sealed Conveying: Utilizing a fully enclosed structural design, it addresses the core pain points of dust generation and contamination during barium sulfate transport. It prevents environmental pollution caused by powder particle leakage and minimizes material loss.

High Adaptability: Supports multiple units connected in series for ultra-long-distance transport, easily adapting to different workshop layouts, warehousing, and production line transport scenarios.

Customization: Offers carbon steel, stainless steel, and PP material options, allowing for matching based on barium sulfate material characteristics and operating conditions. Customized production is supported according to transport scenarios and requirements.

Multi-Industry Adaptability: Meets the barium sulfate transport needs of various industries such as chemicals, building materials, pharmaceuticals, and coatings. Supports 24/7 uninterrupted operation, flexibly adaptable to raw material transport, process integration, and finished product warehousing and transport.

Our factory produces Barium Sulfate Auger Screws with both tubular and trough housings to meet customer conveying needs. The entire series supports customization with multiple materials to adapt to various industries and working conditions.

Tube-type Barium Sulfate Auger Screw: The housing is a closed circular tube structure, the mainstream housing type for barium sulfate conveying. It is constructed using a seamless welding process, providing excellent sealing and preventing barium sulfate powder dust leakage at the source. The smooth inner wall of the housing reduces barium sulfate material adhesion and conveying resistance, making it the preferred choice for long-distance, high-flow-rate barium sulfate conveying.

Trough-type Barium Sulfate Auger Screw: The housing is an open trough structure. A sealing cover can be added to the top as needed to form a semi-closed conveying system, balancing material observation and dust prevention requirements. The open casing design facilitates feeding and cleaning operations, quickly handling small amounts of clumped barium sulfate material during conveying, preventing material blockage, and allowing for flexible integration with various feeding and receiving equipment.

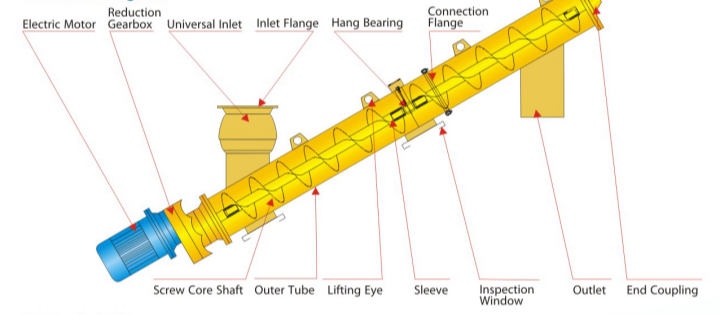

The Barium Sulfate Auger Screw boasts a simple and highly adaptable overall structure. Its core components include a drive system, conveyor cylinder, screw conveyor assembly, and sealed inlet/outlet structures. Customization options are available in carbon steel, stainless steel, and PP.

Drive Transmission System: Composed of a motor, reducer, coupling, and base, this is the core power source of the equipment. It can be equipped with a frequency converter to flexibly adjust the speed according to the barium sulfate conveying volume, preventing material blockage. The coupling is sealed to prevent powder ingress and transmission failure.

Conveyor Cylinder: The main load-bearing structure of the equipment, it adopts a seamless welded, closed-loop tubular/trough design, effectively preventing barium sulfate dust leakage. The smooth inner wall reduces material conveying resistance and adhesion.

Screw Conveyor Components: Available in shafted and shaftless designs, these are the core components for material conveying. Shafted models feature a solid screw shaft and continuous screw blades, offering high rigidity and transmission efficiency. Shaftless models use integrated shaftless screw blades, ensuring a high degree of fit with the cylinder and eliminating dead angles for material jamming, making them suitable for easily agglomerated barium sulfate materials.

Sealed Inlet/Outlet Structure: Includes customized inlet and outlet ports, equipped with soft-seal flanges and dust covers, achieving a completely sealed conveying process and preventing barium sulfate powder from splashing during unloading. The inlet port is compatible with upstream equipment such as silos and grinding mills, while the outlet port supports an adjustable design to accommodate different receiving devices.

The Barium Sulfate Auger Screw works by using a rotating screw to forcefully push the material axially within a closed tank, achieving directional, continuous, and sealed conveying. When the drive unit rotates the screw shaft, the screw blades generate a forward axial thrust on the barium sulfate material entering the tank. Due to the combined effects of the barium sulfate's own gravity and the friction between it and the tank walls and blades, the barium sulfate does not rotate with the spiral blades. Instead, it slides smoothly forward along the tank under the propulsion of the spiral.

| Specifications | Spiral diameter(mm) | Pitch (mm) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | |

| small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3.0 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| medium | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62.0 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

| Material lumpiness | Material grindability | Filling factor | K | A |

| powdery | Unpolished, semi-polished | 0.35-0.40 | 0.0415 | 75 |

| powdery | Abrasiveness | 0.25-0.30 | 0.0565 | 35 |

| Small block a<60mm | Unpolished, semi-polished | 0.25-0.30 | 0.0537 | 45 |

| Small block a<60mm | Abrasiveness | 0.20-0.25 | 0.0645 | 25 |

A chemical new materials company specializing in industrial-grade barium sulfate powder processing needed to achieve a 25-meter long-distance closed-loop conveying distance from the raw material silo to the grinding workshop, requiring adaptability to high-flow conditions and complete dust control. A custom-designed tubular, shafted Barium Sulfate Auger Screw was developed for them. The casing and blades are made of 304 stainless steel, and the fully enclosed, seamless welded structure completely solves the powder dust problem. The variable frequency drive system allows for adjustable conveying capacity, adapting to a production demand of 25 tons per hour. A single 25-meter conveying unit requires no splicing, simplifying the layout and reducing equipment failure points.

The Barium Sulfate Auger Screw offers highly flexible conveying angles. Our products can be customized from 0° to 90° to meet process requirements. However, in typical applications, an inclination angle of 30° to 60° is most common, ensuring high conveying efficiency and stability while lifting materials, suitable for most workshop layouts. When the conveying angle increases to vertical, the barium sulfate will rely entirely on the spiral blades to push upwards, significantly reducing its conveying capacity and efficiency. Therefore, the vertical lifting height of vertical conveying is usually limited to within 5 meters to ensure operational reliability and reasonable throughput.

Yes, it can. Addressing the characteristics of hydrated barium sulfate—its tendency to clump, stick to walls, and poor flowability—we have specially optimized the equipment structure design. The core features a shaftless spiral mechanism with a smooth inner wall cylinder, eliminating dead angles for material jamming. The blades fit tightly against the inner wall of the cylinder, effectively scraping away adhering material and preventing clumping and blockage. We can also customize stainless steel/PP wear-resistant and non-stick materials to reduce material adhesion to the equipment.

Dahan Machinery, as a manufacturer of Barium Sulfate Auger Screws, offers all equipment directly from the factory at factory prices, eliminating middlemen and markups. Prices start from $560. Equipment prices fluctuate based on actual configuration requirements, primarily influenced by materials, conveyor length, and machine specifications. Carbon steel models are suitable for standard industrial barium sulfate conveying; stainless steel and PP models are customized for corrosion-resistant and high-cleanliness applications, with prices adjusted accordingly. Tubular, trough, and shafted/shaftless models also have corresponding pricing standards. Our factory supports non-standard customization quotes, calculating additional costs for roller additions, frequency converters, and other configurations as needed. Our pricing is transparent with no hidden charges, and we provide comprehensive after-sales support, allowing customers to purchase suitable barium sulfate conveying equipment at a reasonable cost.

The Barium Sulfate Auger Screw, through a combination of reinforced structure, wear-resistant materials, special spiral design, and powerful drive, solves the core challenges of high wear, easy deposition, and heavy load in the conveying of barium sulfate materials. It is the key to achieving fast, reliable, and clean conveying in barium sulfate production lines.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!