Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Aluminum Chip Screw Conveyor is a customized conveying device designed for the transfer of aluminum chips, aluminum powder, and aluminum scraps in the aluminum processing industry. It is adaptable to the characteristics of lightweight, easily tangled, and potentially fluid-containing aluminum chips. The core of the device utilizes a screw propulsion principle, with a drive system rotating screw blades within a conveying trough/hose to transfer aluminum chips from the machine tool's chip discharge port to a collection box or recycling equipment.

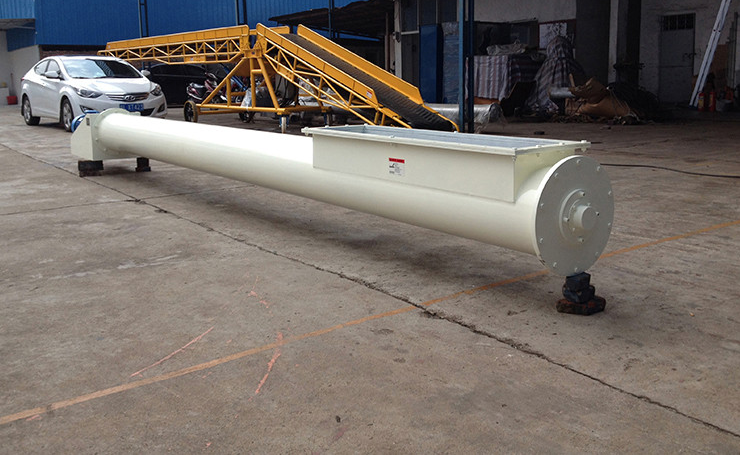

The Aluminum Chip Screw Conveyor is available in carbon steel and 304/316L stainless steel. The maximum conveying length for a single unit is 30 meters, and the maximum pipe diameter is 600mm. It also supports full customization, allowing adjustments to blade type, conveying angle, inlet/outlet configuration, and drive configuration based on the characteristics of the aluminum chips and the site layout. With its flexible adaptability and stable conveying performance, it has become a key piece of equipment for aluminum processing companies to improve waste chip handling efficiency and optimize the workshop environment.

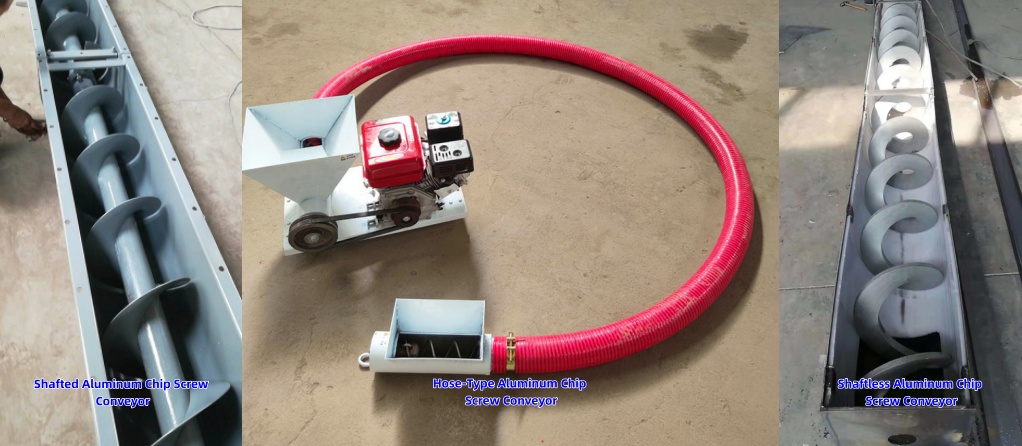

Addressing the characteristics of lightweight, easily entangled, and fluid-containing aluminum chips, our factory produces three main types of Aluminum Chip Screw Conveyors: shafted, shaftless, and flexible. Each type differs in structural design and applicable scenarios to meet the needs of various aluminum processing applications.

Shafted Aluminum Chip Screw Conveyor: Utilizes a solid helical shaft with continuous blades. The shaft and blades are integrated, resulting in high rigidity and ample propulsion. The blades undergo wear-resistant treatment, and the optimized pitch adapts to the fluffiness of the aluminum chips, effectively preventing lightweight aluminum chips from suspending or clogging.

Shaftless Aluminum Chip Screw Conveyor: With no central shaft, it uses hollow helical blades to directly propel materials. It features a compact structure and outstanding anti-entanglement performance. The small gap between the blades and the trough allows it to handle wet aluminum chips containing a large amount of cutting fluid and strong adhesion, preventing material blockage caused by shaft entanglement. The trough can be U-shaped open or sealed for convenient cleaning and maintenance.

Hose-type aluminum chip screw conveyor: Utilizing a highly elastic, wear-resistant hose as the conveying medium, coupled with flexible helical blades, it can bend 360° and requires no fixed installation. The lightweight body, equipped with casters, allows for flexible movement between multiple machine tools and is suitable for confined spaces. The sealed hose structure prevents aluminum chip splashing and cutting fluid leakage.

The Aluminum Chip Screw Conveyor is custom-designed for the characteristics of lightweight, easily tangled, and fluid-containing aluminum chips. With its optimized structure and functional adaptability, it has become the preferred equipment for chip transfer in the aluminum processing industry.

High adaptability: Shafted models use optimized pitch blades, shaftless models have no central shaft design, and hose-type models with flexible helical structures, all effectively preventing aluminum chip entanglement and jamming.

Long service life: Core components are made of wear-resistant carbon steel or 304/316L stainless steel, with polished or wear-resistant surfaces, resistant to aluminum chip friction and cutting fluid corrosion; the drive system is equipped with a high-quality motor and gearbox, ensuring stable operation and long maintenance cycles.

Adaptable to diverse scenarios: Supports horizontal, inclined, and flexible bending conveying. Shafted models have a capacity of 1-15 tons per hour for batch transfer, while flexible hose models can bend 360° to adapt to narrow spaces; equipped with a variable frequency speed control system, the conveying capacity can be precisely adjusted, and it can connect to the chip discharge ports of multiple machine tools.

Strong sealing: Shafted and shaftless models are equipped with sealed tanks and covers; flexible hose models have a fully enclosed conveying structure. Combined with inlet and outlet seals, this effectively prevents aluminum chip splashing and dust diffusion, while also preventing cutting fluid leakage and site contamination.

Convenient installation and maintenance: Simple and compact structure, supporting fixed installation or mobile operation without complex debugging; removable tank cover and inspection port design facilitates cleaning of tangled aluminum chips and routine maintenance.

Customizable: Blade type, material, conveying length, inlet/outlet configuration, and drive method can be customized based on aluminum chip characteristics, conveying distance, and site layout.

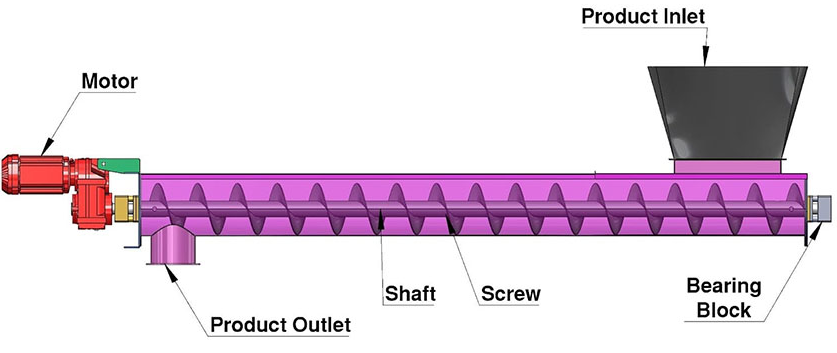

The Aluminum Chip Screw Conveyor's structure is designed around anti-tangling, wear resistance, and adaptability to aluminum chip characteristics. Its core consists of a conveying system, drive system, support and fixing system, and auxiliary accessories. These components work together to ensure stable transport.

Spiral Blades: Available in shafted and shaftless types, made of wear-resistant carbon steel or 304 stainless steel. Blade edges are polished, and the pitch is optimized based on the aluminum chip's bulkiness to prevent tangling and blockage.

Conveying Tank/Hose: Shafted and shaftless models use a U-shaped trough with a pre-drained hole at the bottom and a smooth, non-stick inner wall. The hose type uses a highly elastic, wear-resistant hose that can bend 360° to adapt to complex spaces.

Inlet/Outlet: The inlet is flared or flanged for easy connection to the machine tool's chip discharge port; the outlet can be equipped with a discharge valve or guide chute to prevent aluminum chips from splashing and supports adjustable discharge direction as needed.

Motor: A variable frequency speed control motor or explosion-proof motor is selected. The power is configured according to the conveying capacity and tilt angle, ensuring smooth start-up and low noise.

Gearbox: Used in conjunction with the motor, it increases torque through gear reduction, ensuring low-speed, high-torque operation of the spiral blades and preventing shutdown due to excessive aluminum chip load. The material is mostly cast iron or aluminum alloy, which is wear-resistant and durable.

The Aluminum Chip Screw Conveyor conveys materials through a rotating spiral shaft. When aluminum chips enter the enclosed U-shaped housing from the inlet, the continuous rotation of the spiral blades generates axial thrust, pushing the material forward along the chute to the outlet. The equipment adopts a fully sealed design, with a 3-5mm gap between the blades and the housing, preventing aluminum chip leakage and avoiding entanglement of long strips of chips. Utilizing variable frequency speed control technology, the conveyor speed can be adjusted in real time according to the briquetting machine's capacity, achieving intelligent linkage with downstream equipment and ensuring the continuous and stable operation of the aluminum chip recycling process.

The Aluminum Chip Screw Conveyor, with its adaptability to aluminum chips under different working conditions, has been implemented in multiple industries. We can recommend suitable conveying equipment based on different application scenarios to ensure the normal operation of the entire production process.

Automotive Aluminum Alloy Wheel Factory: Processing thousands of wheels daily, generating 120 tons of wet aluminum chips containing cutting fluid. Previously, manual transfer was inefficient and resulted in significant cutting fluid waste. A centralized processing system consisting of six shafted aluminum chip screw conveyors, combined with crushing and degreasing equipment, was adopted to form an automated production line. The equipment uses a 304 stainless steel tank and wear-resistant blades, with a bottom drain hole to discharge cutting fluid in real time. A variable frequency motor adjusts the conveying volume to match the wheel processing rhythm. After implementation, aluminum chip processing efficiency increased by 80%, and 1800 liters of cutting fluid are recycled daily.

Precision Machining Aluminum Chip Transfer: The customer primarily uses the machined aluminum alloy precision parts for aerospace applications. The five-axis machine tools generate a large amount of ribbon-like aluminum chips, requiring measures to prevent entanglement and vibration that could affect machining accuracy. A Z-shaped layout shafted aluminum chip screw conveyor is adopted, with a 600mm wide collection trough adapted to the machine tool's chip discharge port. The wave-shaped blade design prevents the ribbon-like aluminum chips from entanglement. The equipment occupies only 1.2m x 0.8m of floor space, yet can vertically lift 2.5 meters to a centralized processing box, where a scraper device automatically cleans up residual aluminum chips. After implementation, machine tool downtime due to aluminum chip accumulation has been reduced by 70%.

Multi-Machine Tool Dispersed Aluminum Chip Transfer: The customer has 10 aluminum profile cutting and milling machines, with aluminum chips scattered throughout the workshop. Traditional manual cleaning is inefficient and produces a lot of dust. Four flexible hose-type aluminum chip screw conveyors are introduced. These machines use highly elastic, wear-resistant hoses that can bend 360° and navigate between machine tools. With casters, one conveyor can connect to multiple machine tools. The sealed hose structure prevents aluminum chips from splashing, and the carbon steel blades are suitable for drying aluminum chips. Each unit has a production capacity of 1-3 tons per hour, meeting the needs of small to medium batches. After use, the manpower for aluminum chip cleaning in the workshop is reduced by 2 people, and dust pollution is significantly improved.

| Specifications | Spiral diameter(mm) | Pitch (mm) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | |

| small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3.0 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| medium | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62.0 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

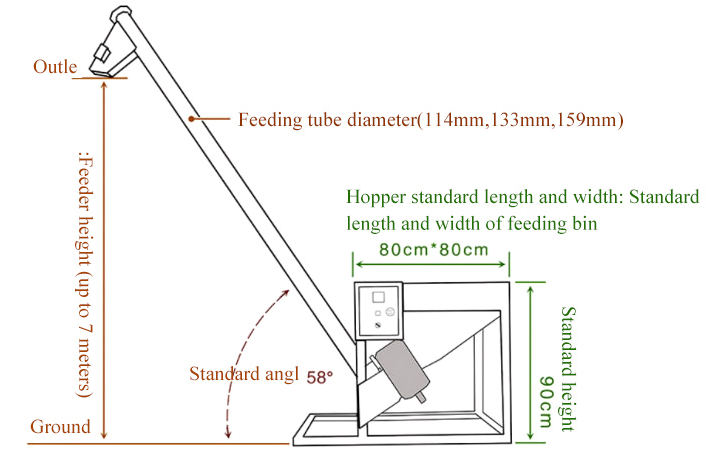

Our factory's Aluminum Chip Screw Conveyor has a full-angle conveying capability of 0°-90°, which can flexibly adapt to the needs of different industrial scenarios. When installed horizontally, the equipment achieves long-distance straight conveying with maximum efficiency, suitable for centralized collection of aluminum chips from the workshop floor; when installed at an incline, by adjusting the screw shaft speed and blade pitch, the influence of gravity can be overcome to stabilize the conveying, which is often used to connect processing equipment and recycling devices at different heights; when installed vertically, the high-torque drive device and anti-jamming design can lift aluminum chips directly from a lower position to the briquetting machine or storage silo, saving horizontal space.

Choosing an aluminum chip screw conveyor requires comprehensive consideration of material, conveying capacity, space adaptability, and customization needs. We support ultra-long designs up to 30 meters; confirm the installation angle based on the workshop layout to ensure stable operation.

Select based on aluminum chip characteristics: For dry/granular aluminum chips, choose a shafted model; for damp/oil-containing/easily sticky aluminum chips, choose a shaftless model; for dispersed small-batch transfers or operations in confined spaces, choose a flexible hose model.

Confirm material compatibility: For ordinary dry aluminum chips, carbon steel is suitable; for environments containing cutting fluid, corrosive environments, or precision machining scenarios, choose 304/316L stainless steel; for flexible hose models, pay attention to the hose's wear resistance and sealing performance.

Match conveying parameters: Determine the conveying capacity based on the daily aluminum chip output, and confirm the conveying length and tilt angle based on the site layout to avoid exceeding the equipment's adaptability range.

Consider installation and site compatibility: For fixed production lines, choose shafted/shaftless models with brackets/feet, supporting horizontal/inclined installation; for multi-machine operation, choose mobile models with casters; ensure equipment dimensions match workshop space and machine chip outlet locations.

Customization services: Choose manufacturers that can customize materials, blade pitch, and inlet/outlet types to avoid incompatibility with other equipment.

DaHan Machinery's Aluminum Chip Screw Conveyors offer 0°-90° omnidirectional conveying capabilities. Products include shafted, shaftless, and flexible hose models, made of carbon steel and 304/316L stainless steel, suitable for dry, oily, and adhesive aluminum chips. Customized conveyor length, pipe diameter, and drive configuration are supported. Free technical consultation and solution design are provided. We can design suitable conveyor equipment to fit your production line. Our products are sold globally, meeting the needs of different manufacturers and suppliers.

The Aluminum Chip Screw Conveyor features a closed housing design, effectively preventing coolant leakage from aluminum chips and avoiding oil contamination of the workshop environment. Its conveying capacity can be precisely controlled by adjusting the screw shaft speed and blade pitch, meeting the continuous production needs of small to medium-sized workshops.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!